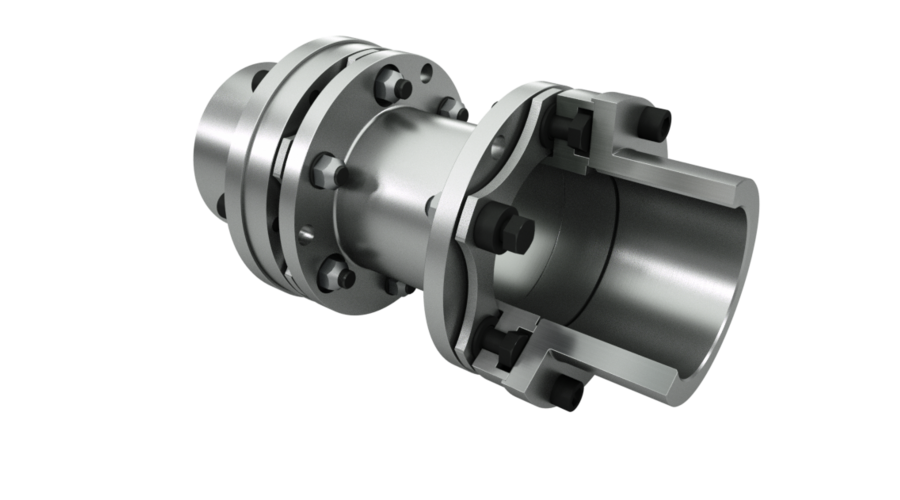

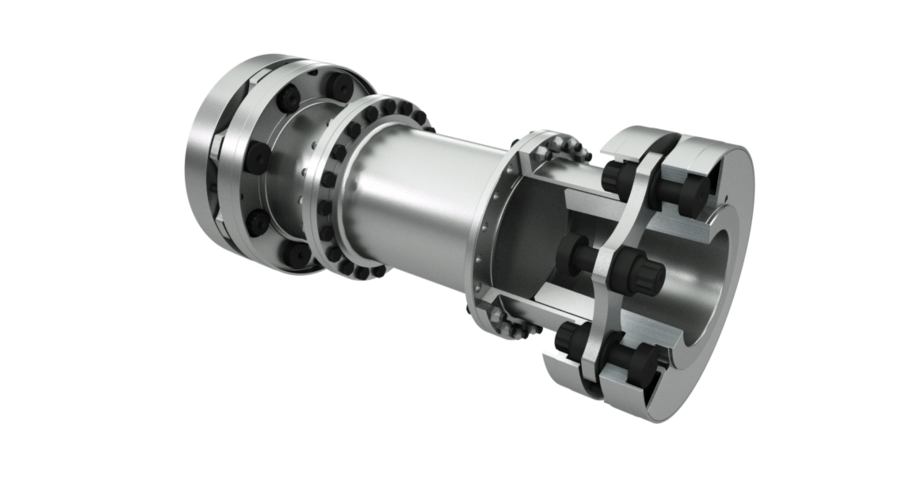

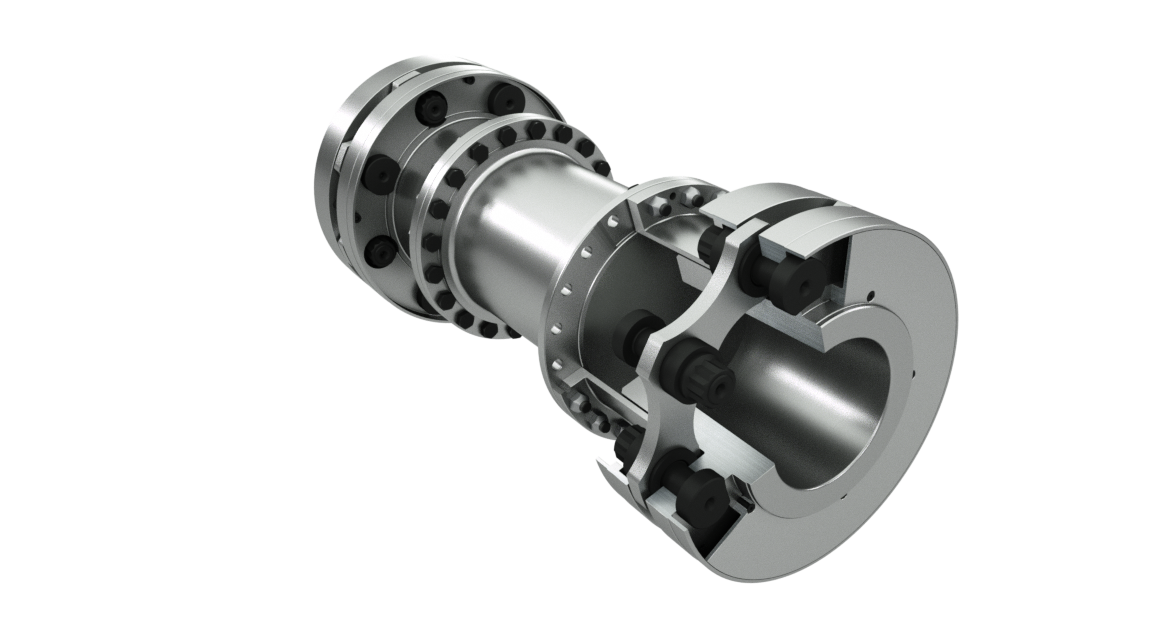

RAFLEX® flexible disk couplings for low speed up to turbo applications

- 01DS – Basic series for lower speeds

- 02DT – High speed series for turbo applications

The RAFLEX® series is designed for various torque applications, with low or high speeds and can handle misalignments. The alternately bolted disk pack of the coupling are made of stainless spring steel. Due to the layered structure of the specially shaped disks, these couplings Couplings Couplings are used to connect two shafts for the transmission of torque, and to compensate for misalignment or movement. compensate for axial, radial and angular misalignment between the driving and driven machines without generating large restoring forces.

High quality materials ensure a long service life even in the most demanding environmental conditions. Depending on the product family, the couplings Couplings Couplings are used to connect two shafts for the transmission of torque, and to compensate for misalignment or movement. meet API 610 or 671 specifications. They can also be used in potentially explosive atmospheres in accordance with ATEX.

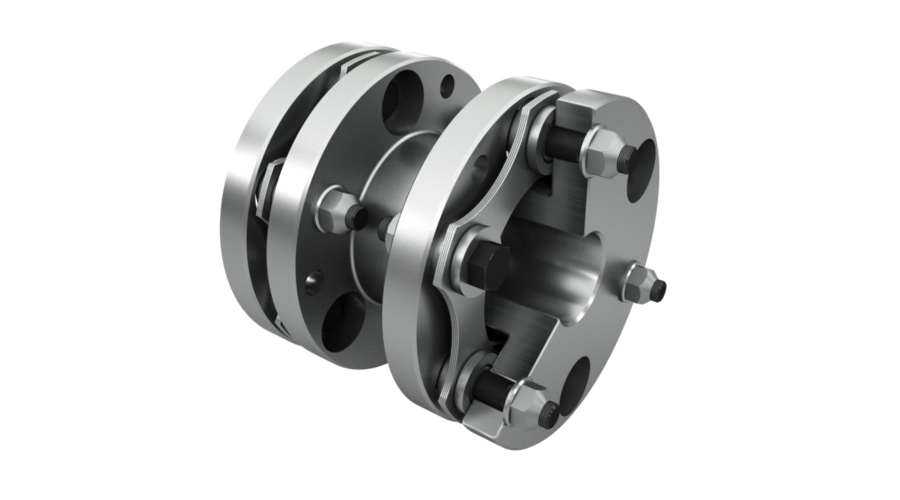

RAFLEX® disk couplings are available in standard 3-bolt, 4-bolt and 5-bolt designs. The different disk variants allow the optimum coupling to be selected for each application. The number of bolts determines the transmittable torque as well as the misalignment capability of the coupling.

DS Series: Flexible disk couplings for lower speeds

The RAFLEX® flexible disk couplings of the DS series are especially suitable for challenging industrial use in the lower speed range.

Typical applications are industrial pumps, fans, presses, crane systems, generators as well as for marine applications.

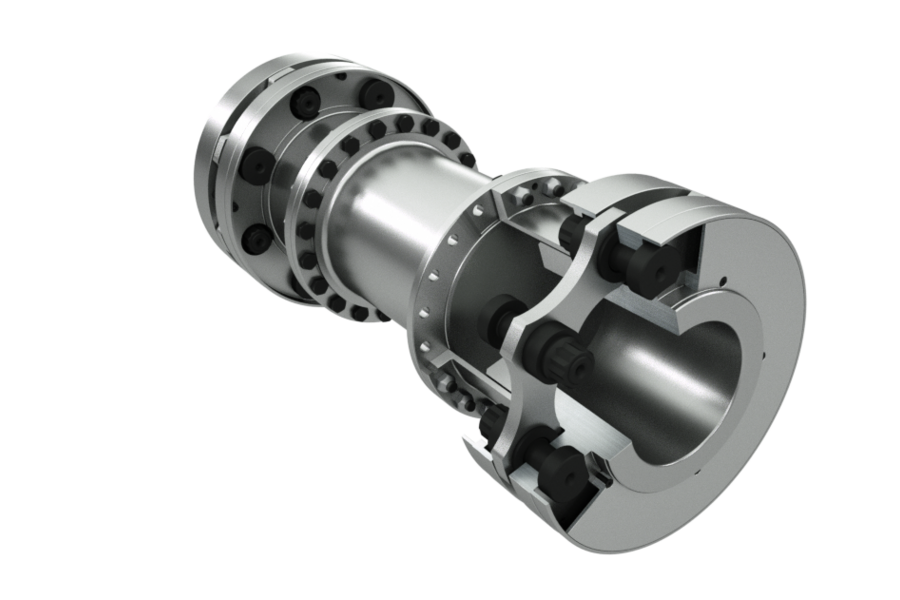

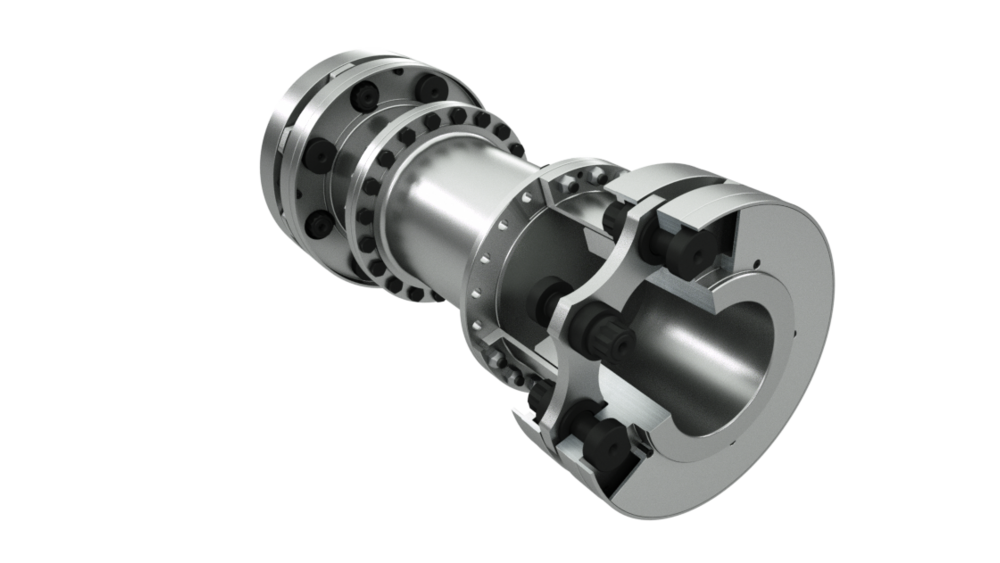

DT series: Flexible disk couplings for high speed applications

The turbo series embraces various flexible disk couplings specifically designed for high speed applications such as turbines, compressors or generators. The RAFLEX® DT disk couplings are noted for their high power density at maximum speeds.

Features of RAFLEX® flexible disk couplings

- Minimal wear therefore high uptime and low maintenance demand

- Torsional rigid and compensating offsets

- High power density

- 3-, 4-, 5-standard bolt designs

- API 610 and 671 compliant

Downloads

- RENK Couplings (3.3 MB)

E-Mail angeben

Bitte geben Sie Ihre E-Mail-Adresse an, um den Download zu starten.

Get in touch with our experts in case of any questions: