Drive performance – with RENK hydraulic safety couplings.

HYGUARD® torque limiting couplings Couplings Couplings are used to connect two shafts for the transmission of torque, and to compensate for misalignment or movement. safeguard your machinery’s drivetrain from overload, protecting your capital goods from damage caused by unexpected overstraining. With constant, individually adjustable release torque, the RENK solution ensures reliability and flexibility throughout the entire operation.

Safety couplings Couplings Couplings are used to connect two shafts for the transmission of torque, and to compensate for misalignment or movement. are used predominantly in heavy industries such as steel, extrusion, mining, cement, locomotives, and test stands. RENK offers a range of design types to suit your requirements, whether for a new build or installation, or to replace an existing solution. Our broad range of torque-limiting couplings covers capacities of up to 10,000 kNm and speeds up to 7,500 rpm

With over 150 years of expertise, RENK understands your industry inside out. As a global leader in drivetrain technology, we deliver performance, reliability, and innovation.

HYGUARD in action

In less than two minutes, find out how HYGUARD safety clutches protect your drivelines against overload.

The HYGUARD® advantages at a glance

- Excellent price/performance ratio (CAPEX)

- Can be combined with all types of couplings

- Quick availability

- No additional energy costs for operation

- Constant trigger torque throughout the entire period of operation

- Torsionally rigid-flexible connection of shafts

- Overload protection with adjustable torque limitation

- Release accuracy of +/- 7–10%

- No stoppages due to material fatigue, resulting in low downtime costs

- No decline in triggering accuracy over time

- Transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. of high torques in a small space

- Quick re-commissioning

- No operational wear and tear, therefore no maintenance costs

- No cost-intensive stocking of spare parts

HYGUARD® torque limiting couplings – easy to operate, reliable in execution.

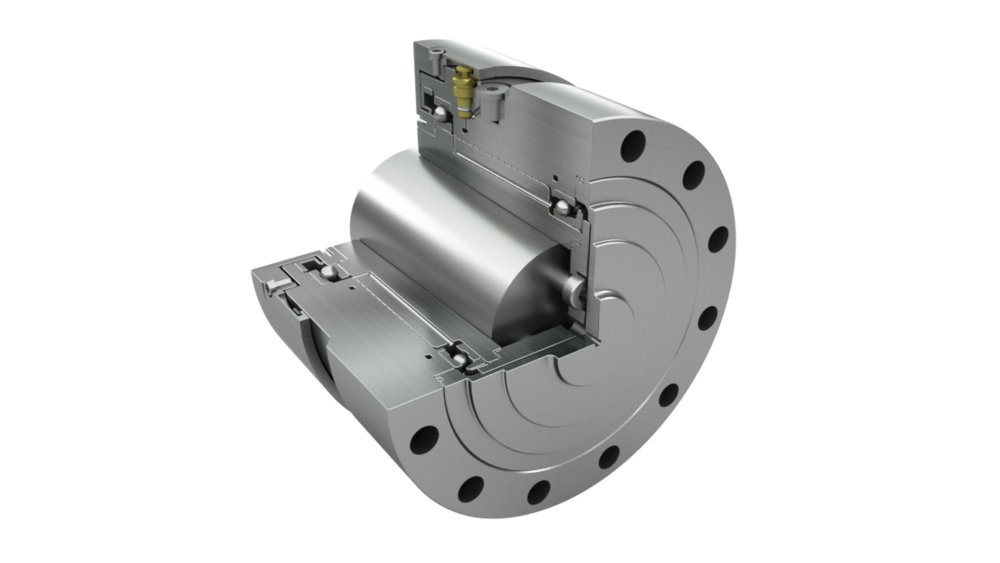

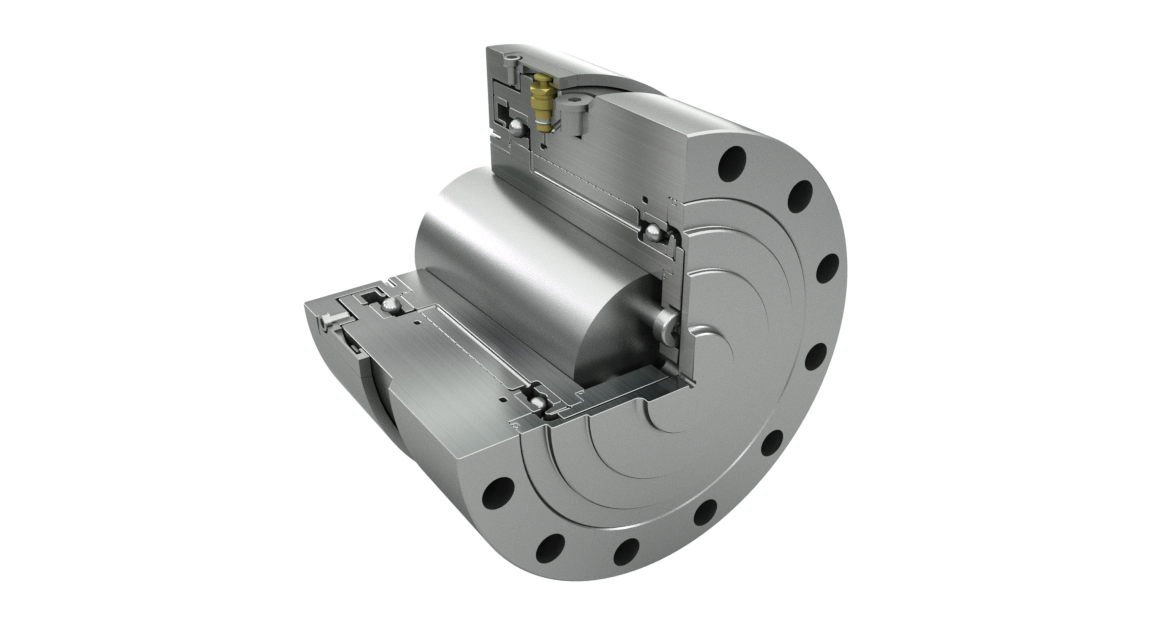

Appropriate safety equipment is required to protect drivetrains in industrial plants. This includes torque limiting couplings, which are available in a wide range of designs. The HYGUARD® hydraulic safety couplings transmits torque solely by friction between the hydrostatically loaded surfaces of the shaft and hub. It operates without slippage as long as the set torque is not exceeded.

If the torque exceeds this value, the hydrostatic pressure is quickly released, immediately interrupting the driveline. Recommissioning takes very little time. The system simply needs to be pressurised again.

Components of the HYGUARD® torque limiting couplings

- Shaft

- Shear ring

- Injector connection

- Shear tube

- Screw plug for lubricant filling

- Double-walled clamping element

- Seal for lubricant filling

- Coupling hub, gear wheel, or other driving element

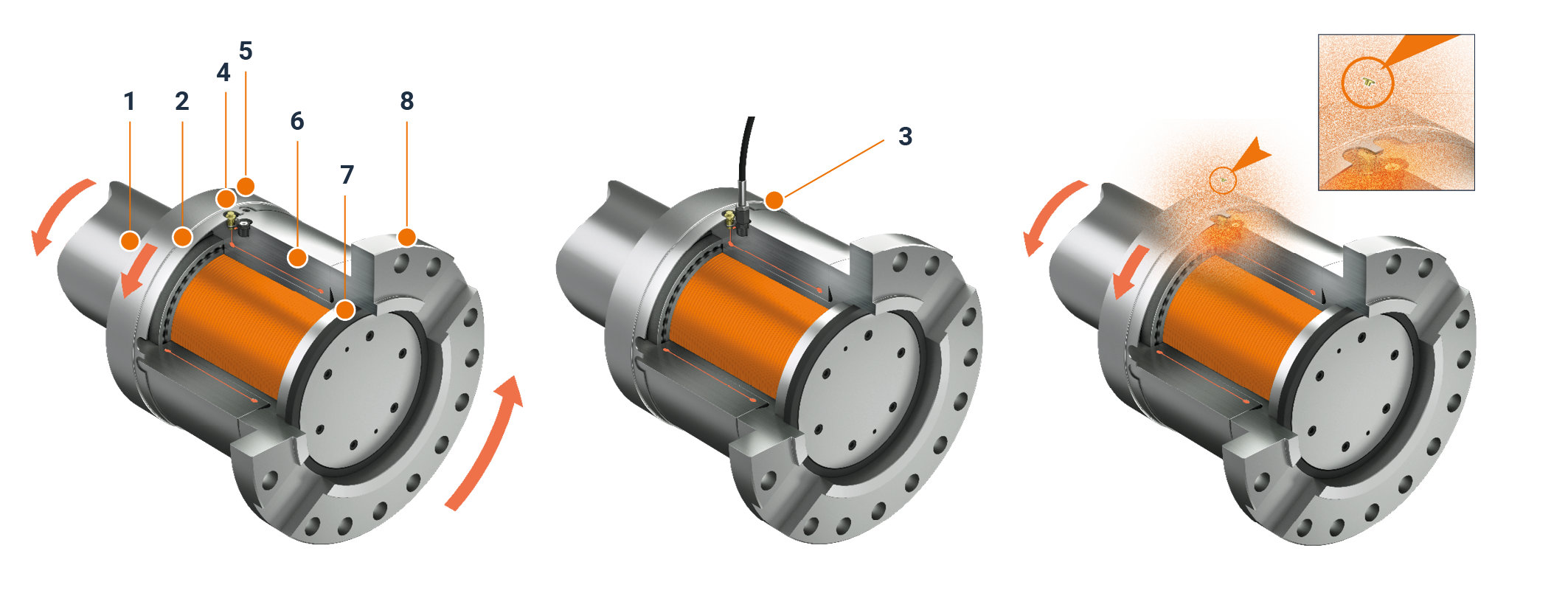

Principle of operation

- Two bushes are inserted into each other, both ends of which are closed in a pressure-tight manner.

- The gap gets pressurized with a hand pump.

- Torque is transmitted by frictional engagement between the contact surfaces.

- Torque vs. pressure according to the calibration diagram provided by RENK.

- When the release torque is exceeded, the safety element will slip on the profiled surfaces and the shear ring will cut off the shear tube.

- The pressure drops within milliseconds, and the hydraulic safety coupling releases the connection.

HYGUARD® Control System – the smart extension of the standard HYGUARD®

The HYGUARD® safety coupling reliably protects your drivetrains from damage caused by overload. The intelligent HYGUARD® Control System takes this protection to a new level: PLC-controlled electronics monitor torque, speed, and position in real time and enable immediate, active responses according to specified parameters.

This allows torque peaks to be specifically limited, slip to be controlled, and overload situations to be detected at an early stage. As a result, you achieve higher plant availability, longer component service life, and fewer unplanned downtimes.

In production facilities with continuous processes, on test benches, or in process engineering plants, even short torque peaks, for example when starting up the equipment, can lead to damage or long downtimes. Classic safety couplings disconnect the drive – this protects the equipment but interrupts the process.

The HYGUARD® Control System goes one step further: it immediately detects overload situations, regulates dynamically, and thus enables continuous production despite load peaks.

The HYGUARD® Control System is designed to be easily connected to common control systems. Depending on customer requirements, we either supply a compact control system or provide only the necessary signals that can be integrated directly into your existing Programmable Logic Controller (PLC). Your control architecture remains unchanged and integration is as flexible as possible. For applications in potentially hazardous environments, we supply suitable solutions on request, including ATEX-certified versions.

- Real-time monitoring of torque, speed, and position directly in the drive train

- Slip and trip detection for immediate notification of the operator

- Condition monitoring Condition monitoring Condition monitoring involves continuously monitoring technical systems to detect deviations or damage early on. : continuous tracking of the drive status for transparency, safety, and efficiency

- Adjustment possible via PLC control

- Continuous production through torque limitation without disengagement

- Cost advantages through reduced maintenance, fewer downtimes, and smaller dimensions

- Integration into digital production systems and cloud solutions for analysis and optimization

HYGUARD® Control System is your active component in the drivetrain: monitoring, informing, controlling. For maximum safety, productivity, and efficiency.

RENK service for your industry

Our industrial services and solutions specialists offer numerous advantages for your projects and plants. These include improving energy efficiency, reducing emissions and costs, and increasing the uptime and safety of your plant. In this we act globally, promptly and throughout the lifecycle of your plant.

Downloads

- Hyguard® safety couplings (824 kB)

E-Mail angeben

Bitte geben Sie Ihre E-Mail-Adresse an, um den Download zu starten.

- RENK Couplings (3.3 MB)

E-Mail angeben

Bitte geben Sie Ihre E-Mail-Adresse an, um den Download zu starten.

Relevant products

Get in touch with our experts in case of any questions: