Our vertical shaft bearings – a reliable foundation for efficiency

Easy to integrate, yet hard to surpass: vertical shaft bearings for high axial and radial forces

RENK vertical bearings of the EV and V series cover the entire range of applications for slow- to high-speed vertical machines. Based on proven RENK designs, they can be perfectly matched to the specific performance and speed range of vertically installed pumps, blowers, turbines or electric machines. As a pure guide bearing or as a combined thrust-and-guide bearing, they offer the highest quality and unlimited service life.

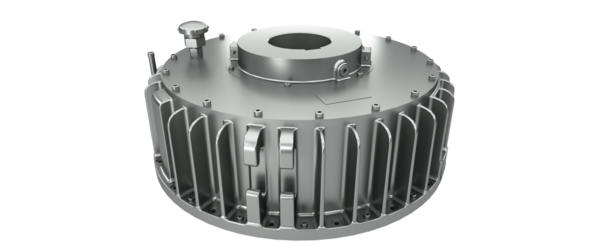

The V series for slow-to-medium shaft speeds

The vertical bearings of our V series are designed for slow-to medium-speed vertical machinery such as pumps, blowers, turbines or electric machines.

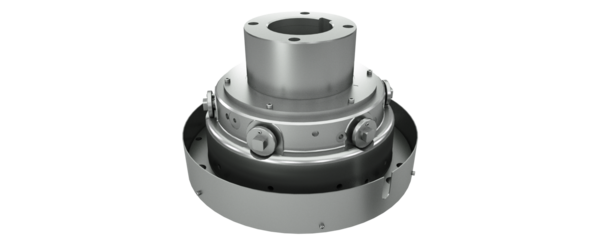

The fast running EV series

RENK vertical bearings of the EVE/EVF series are the experts when it comes to making fast running machines of vertical design permanently efficient.

Vertical bearing with highest flexibility and optimized for efficient operation

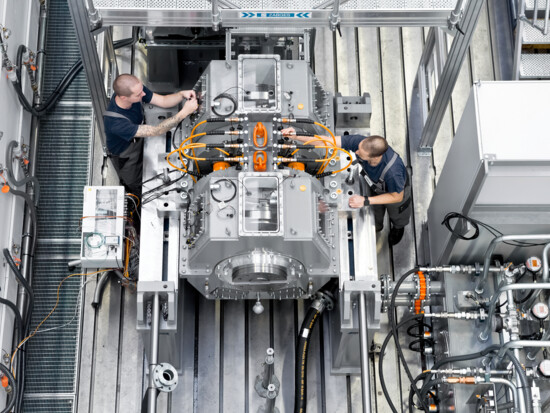

With decades of experience and a large installed base of proven vertical bearings, we can not only tailor bearings to your operational needs, but also manufacture them to the highest standards. Our engineers and manufacturing experts take pride in the quality of their bearings and the features they incorporate.

With our broad technology and basic product portfolio, our experts can customize our bearings according to the needs of the application. As an example: To accommodate higher axial loads, the RD-thrust pads can be designed to inject high pressure oil from a hydrostatic jacking system.

Get in touch with our bearing experts to discuss your requirements.

Depending on the respective operating conditions, the vertical bearings are operated with natural cooling, external lubrication, or integrated water coolers. Using a fan expands the range in which natural cooling can be used to include higher speeds. If there is an external lubricant system, the housing is equipped with an overflow chamber that always contains enough lubricant for short-term emergency operation until the machine is shut down.

Reducing noise and vibration also means reducing friction and thus energy loss and wear. This is where RENK bearings excel, thanks to decades of experience in engineering and manufacturing combined with state-of-the-art production facilities and quality control.

With the expertise from RENK and the monitoring of the bearing temperature, the condition of the bearing can be easily analyzed. This enables more effective planning of service intervals and helps to avoid unexpected downtime.

Get in touch with our experts in case of any questions.