Services for slide bearings from the manufacturer

RENK offers the full range of service and support for optimal performance of your slide bearings.

Although RENK slide bearings Slide bearings Slide bearings facilitate the low-friction movement of shafts by coming into direct contact with a sliding surface. are extremely robust and durable, they can wear out and reduce efficiency or, in the case of severe damage, cause the drive train to fail.

As an original equipment manufacturer of high-quality bearings, we offer a comprehensive range of services for both our own and third-party bearings to maximize performance and uptime. These services include:

- Spare part management

- Refurbishment

- Field service

Ensuring operational continuity: fast spare parts delivery.

Minimize system downtime and associated risks with original spare parts.

The (preventive) maintenance of slide bearings Slide bearings Slide bearings facilitate the low-friction movement of shafts by coming into direct contact with a sliding surface. in your plant or vessel ensures high availability. RENK supports you with global availability of spare parts such as bearing shells or peripheral parts such as seals. For the fastest delivery times, we stock locally and offer an onlineshop in addition to direct contact with our experts.

At RENK, you have the leading experts in the field of hydrodynamic slide bearings at your disposal. Explicit analysis and advice on damage mechanisms of the bearing itself and interactions with other components in the drive train are therefore a real added value for our customers.

Save costs with reconditioning your slide bearings.

Bearings are sometimes remanufactured for cost reasons or to ensure compatibility. Of course, we offer this service for our own bearings as well as for third-party products. We have extensive experience and methods to bring products virtually up to date.

The key advantages of our slide bearing Slide bearings Slide bearings facilitate the low-friction movement of shafts by coming into direct contact with a sliding surface. refurbishment:

Faster delivery of the remanufactured bearing than manufacturing a new bearing. Less downtime for your equipment.

Refurbished bearings are functionally reliable and re-babbitted. This is a functional repair so that the bearing performs similarly to a new bearing.

Refurbished bearings need approximately 65% less energy and thus fewer resources compared to manufacturing of new spare parts. This contributes to our customers' environmental goals by reducing emissions.

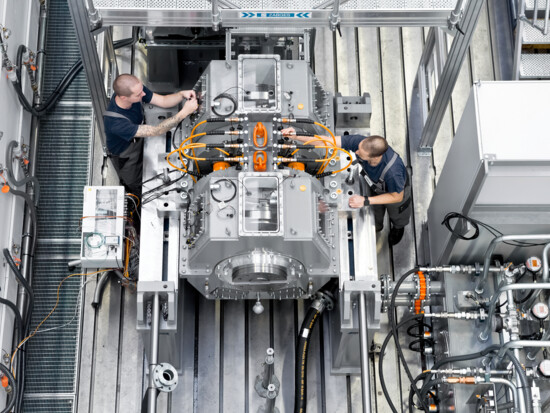

As a leading manufacturer of high-end bearings, our target is to ensure the superior quality of our refurbishment work by leveraging the expertise of our professionals and cutting-edge production and metrology equipment.

On-Site expertise: reliable field service for slide bearings

Our global team of service technicians provides on-site services such as reassembly, maintenance and adjustment of complex bearing systems – so your drivetrain performance meets your demands and expectations.

Interested in our slide bearing services?

We would be happy to support you with our experience and competence. Contact our experts and send us your questions and requests.