150 years full of stories, innovations, and passion

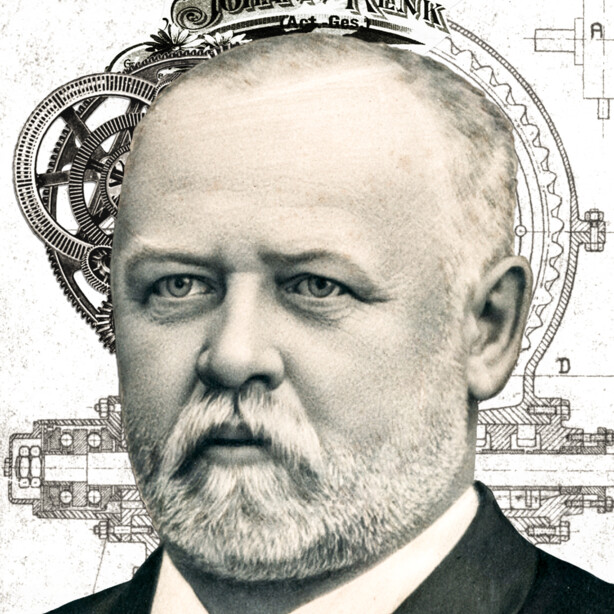

A pioneer of the industrial age founded RENK

Our founder started RENK in a garage in Augsburg. Thanks to his passion and innovations the garage was not sufficient anymore and the first factory was needed.

Key turning point

The “Zahnräderfabrik Augsburg” joint-stock company for the production of gear wheels is founded.

Quantum leap

RENK constructs a gear cutting machine with a processing diameter of seven meters.

Breakthrough

500 precision automotive gear units each month.

Milestone

The first reversing gear units for marine applications are built.

Record

RENK builds the fastest gear box in the world.

New invention

RENK causes a paradigm shift in the transfer of power and energy for tanks to the principle of hydrostatic superimposition steering.

Global innovation

RENK produces the first turbine gear box with the highest pitch circle velocity (185 m/s).

Shifting gears

RENK builds the first vehicle transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. dynamometers for tanks with automatic transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. .

Pure innovation

RENK invents the hydrostatic-hydromechanical steering drive for tracked vehicles Tracked vehicles A tracked vehicle is a vehicle that moves on tracks rather than wheels, typically used for rough terrain. .

All inclusive

RENK designs the first integrated braking system with friction brakes.

Maximum control

Development of the RENK checker - an electronic device for monitoring gear boxes.

Even more dynamic

Acquisition of the slide bearing Slide bearings Slide bearings facilitate the low-friction movement of shafts by coming into direct contact with a sliding surface. and coupling product areas of Eisenwerke Wülfel in Hanover.

Global pioneer

RENK becomes the world's first company in the field of drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles. to harden and grind gear wheels measuring over 3,000 mm in diameter.

Gigantic

RENK manufactures one of the largest marine gear boxes for ice going ships with a diesel motor drive. Power: 40,000 kW.

Trailblazing technology

Based on the company’s expertise in the development of electronic control devices for automatic transmissions Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. , the RDDS (RENK dynamic data system) was created for controlling a drive shaft dynamometer, and is still used in the area of development in Formula 1 motorsports today. The RDDS has been continually enhanced since this time.

New venture

The product areas of industrial and marine gear boxes are spun off into RENK-TACKE GmbH.

The RENK AG

The company's name is changed to RENK Aktiengesellschaft – including the product areas of automatic vehicle transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. , drive elements, and test systems Test systems Test systems evaluate the functionality, load capacity and wear of technical components under realistic conditions. .

In a class of its own

RENK produces a turbo gear box with the highest power rating ever transmitted by gears in mesh: 75,000 kW.

Vice Versa

RENK builds a planetary gear box for a marine propulsion system with counter-rotating propellers – with an unbelievable performance potential of 20,600kW.

Full turbo

First type of the world's most powerful gear box with a gas turbine output of 90 MW.

Merger

RENK-TACKE GmbH is fully incorporated into RENK AG.

Maximum boost

The output of a turbo gear box increases to 100 MW gas turbine output for the first time.

Big debut

Delivery of a bevel planetary gear unit weighing 110 metric tons, designed for an output of 5,400 kW. The gear unit is used in the world’s largest and most powerful roller mill at a cement works in Argentina.

New dimension

RENK presents the newly developed etaX® gear box for a higher degree of efficiency.

Major feat

The first CODAG CODAG Combined Diesel and Gas is a marine propulsion system that combines diesel engines and gas turbines to drive the same shaft, depending on operational needs. system in the world for the main propulsion system of a frigate with a total output of 38 MW.

Above and beyond

The first RENK AEROGEAR gear box is installed in the AREVA 5-MW system at the Alpha Ventus Offshore Wind Farm in the North Sea.

Premiere

First type of the high-capacity marine propulsion gears for COGAG COGAG Combined Gas and Gas is a marine propulsion system where two or more gas turbines drive the same shaft. Individually or together. arrangement with the lowest specific weight in the world and a total output of 6,300 kW.

Strategically important alliance in 2007

The founding of RENK-MAAG GmbH in Winterthur, Switzerland, and thus the takeover of MAAG’s successful turbo series as well as the global service for the turbo and marine gear units.

Pinnacle of development

Production of a multiple power splitting gear box with a multiflow for an output torque of 15 million Nm – which is approximately three times greater than any previous torques.

First approval of CODELAG hybrid propulsion

The approval of the first system in the world built for the hybrid propulsion of a frigate, CODELAG, with an output of 30,000 kW.

Gateway to Asia

RENK opens a central base, RENK Shanghai Service and Commercial Ltd. Co.

Gigantic

The world's largest planetary gear box for a wind power nacelle test rig is built – with a torque of 15,000 kNm.

Three records in one year

- COPE, the most powerful cement mill gear boxes thus far with an eight-motor drive and an output of 10 MW.

- The world’s largest spur gear box (290 metric tons) for the propulsion of the cutting head of a head suction dredger with a torque of 2.5 million nM.

- First AED electric drive module for extremely low-noise marine propulsion systems.

A superlative scale

The world's largest test stand for gear boxes up to this point is built.

Extending the mobility solution package

RENK buys the Horstman Group, a leader in suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. system for military vehicles. With this move, RENK is strengthening the position of being a holistic mobility solution provider.

Stronger in the Americas

RENK acquires from L3Harris the Technologies Combat Propulsion Systems, an established mobility solution provider.

150 years – a success story continues

In 1873, Johann Julius Renk founded our company in a garage in Augsburg. An incredible and successful journey of 150 years. Made possible by passionate, innovative and incredible employees, customers and partners. Something we will celebrate by innovating our logo and branding.

RENK Group AG goes public again

In February, RENK made a highly successful return to the stock market. Investor demand was so strong that the placement volume was increased to 33 million shares. Just three months after the listing, RENK was admitted to the SDAX index of the German stock exchange.

HSWL 076: A new generation of light vehicle transmissions

With the HSWL 076, RENK expands its HSWL family with a compact, high-performance transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. for light tracked vehicles, developed in a record time of just two years in close cooperation with Patria and designed for digital, hybrid, and future autonomous applications.