RDDS – RENK Dynamic Data System

- 01Unlimited flexibility

- 02Increasing automation

- 03Maximum digitization

- 04Unique operator support

Our technologies for your demands

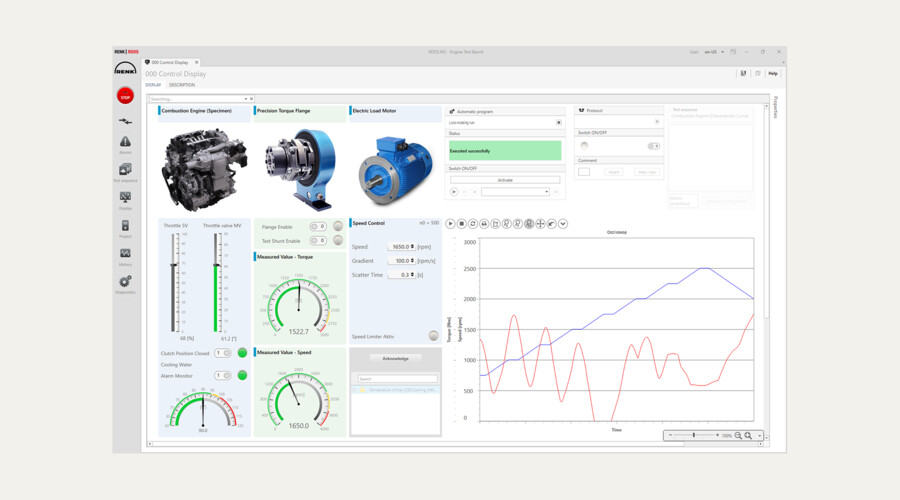

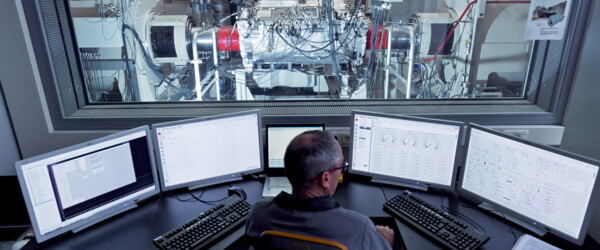

The value of a test rig depends significantly on its control system.

Based on almost 70 years of experience in operating test benches, RENK has developed an automation system that focuses absolutely on the safe and successful execution of the test task.

With RDDS, a very powerful tool is available that combines all basic processes on one interface and makes RENK a fully comprehensive system provider in the field of test rig technology

Python now available in RDDS

Unlock new opportunities for automation and digitization: Discover the full-featured Python editor now integrated into RDDS Release v1.24

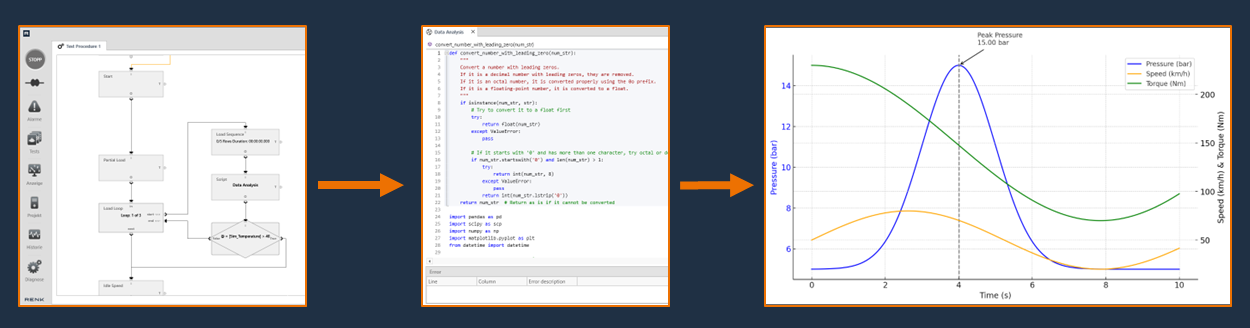

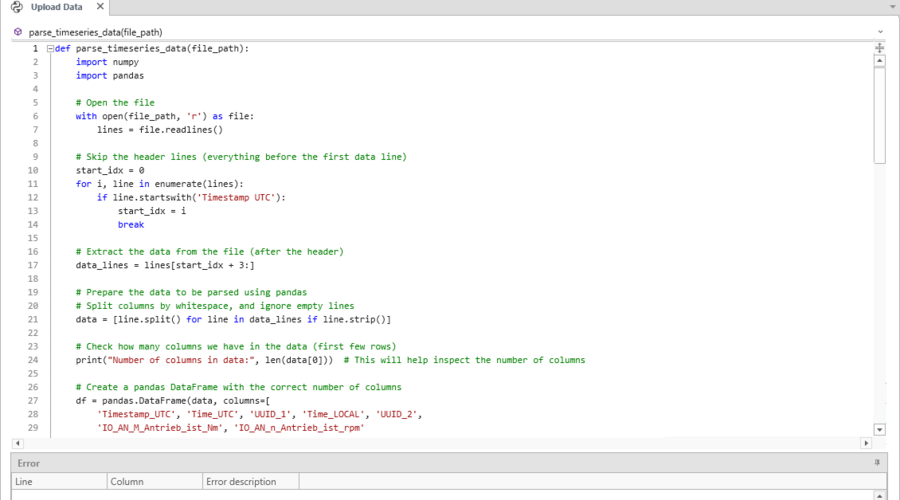

RDDS enables flexible automation of test rigs and test sequences. With Python, users benefit from a powerful tool for data connectivity and processing — backed by a vast ecosystem and powerful libraries such as Pandas, Matplotlib, NumPy, Requests, and TensorFlow. The Python code can be written in the integrated RDDS Python IDE and has direct access to RDDS variables and measurement data.

Join the Python community. Together, RDDS & Python take test bench automation to the next level – paving the way for smarter and more efficient testing processes.

Use cases:

RDDS runs a test program and records the measurement data from the gear shift test so it can be repeated. With Python integration, you can automate more complex calculations with bigger data sets like the gear shift test and analyze them “in-line,” meaning right in the test sequence. In this example, shifting times and shifting quality are analyzed. The result is available directly during the test sequence and can thus be used for further testing or quality evaluation. The end customer can edit the Python script directly with the RDDS client if test criteria need to be changed or expanded.

Building on this, inline data analysis also opens up completely new testing opportunities. For example, target values can be adjusted dynamically based on the analysis results (“closed loop”) in order to intentionally drive test specimens to resonance points. More intelligent evaluation methods and automatic anomaly detection for end-of-line testing are no longer a technical obstacle thanks to the extensive Python libraries.

Python can be used to automatically process a wide variety of data formats. Even complex devices or systems with APIs beyond simple fieldbuses can be easily connected with Python. In an end-of-line test rig, for example, the measurement results (xml format) from an external structure-borne noise measurement system are automatically loaded into RDDS and parsed. The results are used for automated evaluation of the test object (pass/fail) and, at the end of the test, are uploaded to the customer's quality database together with the remaining results via a RESTful interface. The combination of RDDS and Python thus enables a fully automated and digital testing process.

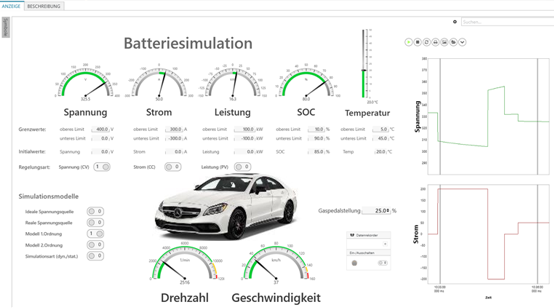

Flexible adaption of the test task

Today's development cycles for technical products are becoming shorter and shorter. Test specifications are constantly being adapted to new requirements.

-> With RDDS, the test bench operator can flexibly adapt test sequences, functions and test reports on the test bench to meet changing requirements in product development.

-> For optimal utilization of the test stand, different test setups can be stored in RDDS and flexibly loaded as required.

-> RDDS is based on Beckhoff TwinCAT 3 realtime system. This guarantees maximum reliability and compatibility regarding hardware interfaces and extensions.

Easy automation and standardization

With automating and standardizing the testing process, operators can handle even the most complex test scenarios and equipment, all while reducing development cycles for your products.

-> Test procedures can easily be automated by graphical editors.

-> Increasing the degree of automation of a test system Test systems Test systems evaluate the functionality, load capacity and wear of technical components under realistic conditions. reduces costs and increases the quality of results.

-> External devices can also be automatically controlled and integrated with RDDS, so the operator can concentrate on the test task.

-> RDDS is designed for all kinds of test rigs in heterogenous test fields. This enables operators to easily switch between rigs, comparable results and streamlined service and support through one central contact.

Digitization of testing processes

Modern quality assurance and the further processing of measurement data lead to increasing demands on measurement and production data.

-> With RDDS, all results and information are stored in a database in a traceable manner. This enables statistics on product quality and process performance.

-> The open interfaces of RDDS also enable the integration into the existing software landscape of the test facility.

Maximum support and customization

As “Trusted Partner”, we prioritize being close to our customers and assist the operator quickly and uncomplicated.

-> RDDS combines engineering and operation in a single tool. This enables our customer support to efficiently assist the operator on-site or remotely, without the need of special tools or code compilation.

-> With intuitive graphical interfaces, operators can quickly trace and troubleshoot errors and make changes without requiring further assistance.

-> In our continous development of RDDS, we focus on compatibility to support our customers with updates and new features.

Features

- Automation system for all types of test benches

- Flexible customization and functional extensions

- Self-explanatory program generation due to innovative graphical editors

- Signal flow oriented modeling of complex automation and control processes

- MATLAB Simulink integration

- Preparation of new test runs independent of active test operation

- Central recording of all relevant measured values generated on the test bench

- Online display and automated reporting of test results

- Structured storage of all test run data

- Modular system for flexible use and easy upgrade

- Open and stable real-time environment (Beckhoff TwinCAT 3)

- Monitoring safety control for unattended continuous operation

- Suitable for new installations and retrofits

- Various license models available for use in third-party test stands

- Continuous development for updates and new features

Take a look at our stories

RENK Dynamic Data System: as versatile and reliable as a Swiss Army knife

Development of a new type of overall vehicle test rig for motorcycles with the RENK automation system RDDS

Modernisation of an aged brake test rig at the Kolejnictwa Railway Institute

Transparent test field thanks to RENK Smart Monitoring

Do you need more information about our RDDS test rig automation system?

Send us your questions and demands.

Get in contact with our experts from

Team RDDS: