Huge experience and unlimited innovation

No limits

Our core competence is in the field of special plant engineering. In the development of test rigs, which are individually tailored to the special requirements of our customers.

The enormous bandwidth of our engineering services is best described by the maximum values of previous test bench projects:

Drive power: up to 100 MW

Torque: up to 44 MNm

Bending moment: up to 113 MNm

Speed: up to 50,400 rpm

And between these characteristic values (or even beyond), we look forward to any task.

In order to build up this know-how and develop it further over decades, we are often pioneers in the application of new processes and methods.

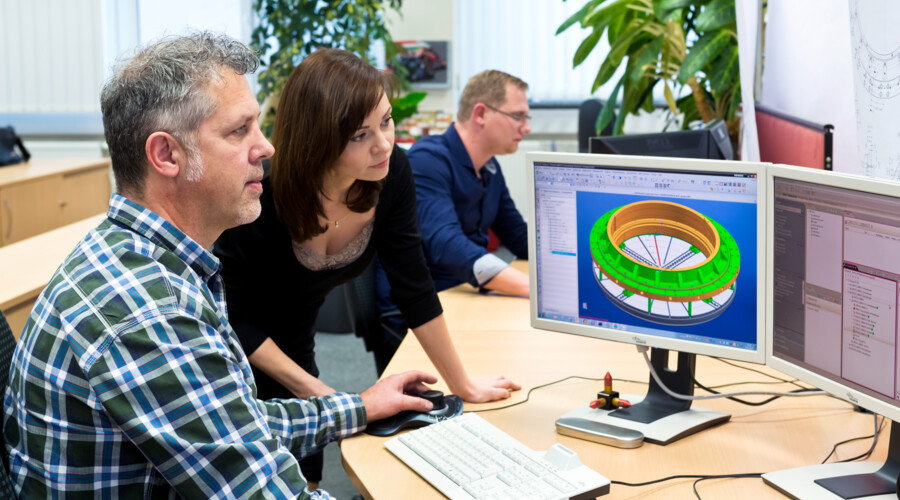

Mechanical and electrical design

RENK is one of the world's leading specialists in drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles. . Many core competencies of the RENK Group can be bundled in unique test rigs. These competencies naturally also include the use of state-of-the-art calculation and simulation methods.

But because our solutions also often take us to the edge of physical limits where standard methods no longer work, we have had to develop numerous in-house design procedures.

This often allows us to create solutions for our customers that others cannot implement.

And always in focus:

The best possible and reliable test rig solution for the testing task.

Software development

Realizing that available control software did not meet our own requirements for satisfactory test rig operation, we started in 1985 to develop the RENK Dynamic Data System, our own RDDS automation system for test rigs. What started then with analog controllers and DOS programming is today a trend-setting real-time automation system that supports the test bench operator in all his tasks.

The constant exchange with the users of this system at the customer and at our own test benches will continue to drive the development of our RDDS to meet future requirements.

With the clear goal:

Ease of use and reliable operation, so that the test bench operator can concentrate on his testing tasks.

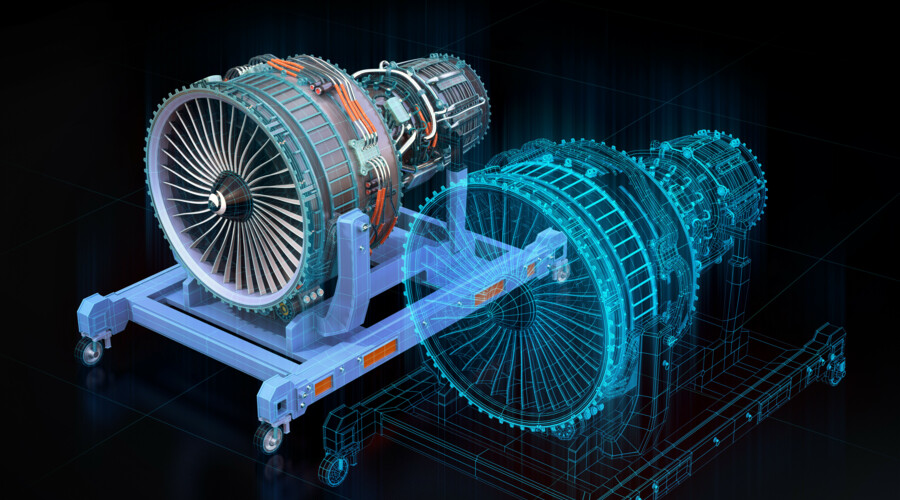

Digital twins

We consequently develop our test stands with digital twins. These virtual replicas of the test specimen open up numerous application possibilities both for the test rig manufacturer but especially for the user. We can use the digital twin to perform a virtual commissioning before the real machine is operated. This increases quality while reducing development time and thus costs.

The user of the test bench can use the digital twin to virtually check his test campaigns as well as target values in advance with the aim of optimizing the test rig utilization.

Furthermore, a virtual replica of the DUT offers the user the possibility to match model and reality in order to optimize the model and increase the fidelity to reality. The resulting optimized models can have multiple applications in the DUT manufacturer's development process.

Our capability:

By using digital twins, we can not only massively support our customer's testing tasks, but also their development work.

Digitization of the construction site

The coordination between high-precision test rig technology and structural and civil engineering requires special measures. For this reason, we document and digitize the building status on site at regular intervals for complex test stands. We can compare the building models generated in this way with our CAD data and take the appropriate measures immediately in the event of any discrepancies.

Our advantages thereby:

Reduction of interface difficulties by maximum digitization also on the construction site.

AR remote support of the assembly

AR is used to support on-site personnel in their activities during assembly, commissioning and service. Through glasses with a camera, the personnel on site and the experts in Germany see the same thing, which is the machine and its components. Information from the experts at home can be virtually fed into the field of vision of the person wearing the glasses on site, allowing them to be instructed and supported quickly and precisely.

Our step into the future:

Maximum support for the customer in all aspects of the test rig by digitalizing our processes to the greatest possible extent.