First time in use – and immediately a double success: With UNOREX and MIREX, RENK is launching two new gear unit solutions for polyolefin production and compounding/plastics finishing. The applications are aimed at polyethylene (PE), polypropylene (PP), and specialty polymers. Both are tailor-made for the customer and mark an important step in the further development/expansion of the RENK portfolio.

With the market launch of the new UNOREX and MIREX gear types, RENK is expanding its range in the field of extrusion – and demonstrating how technological innovation, decades of industry experience, and strategic customer development work together seamlessly.

Two products, two continents, one goal

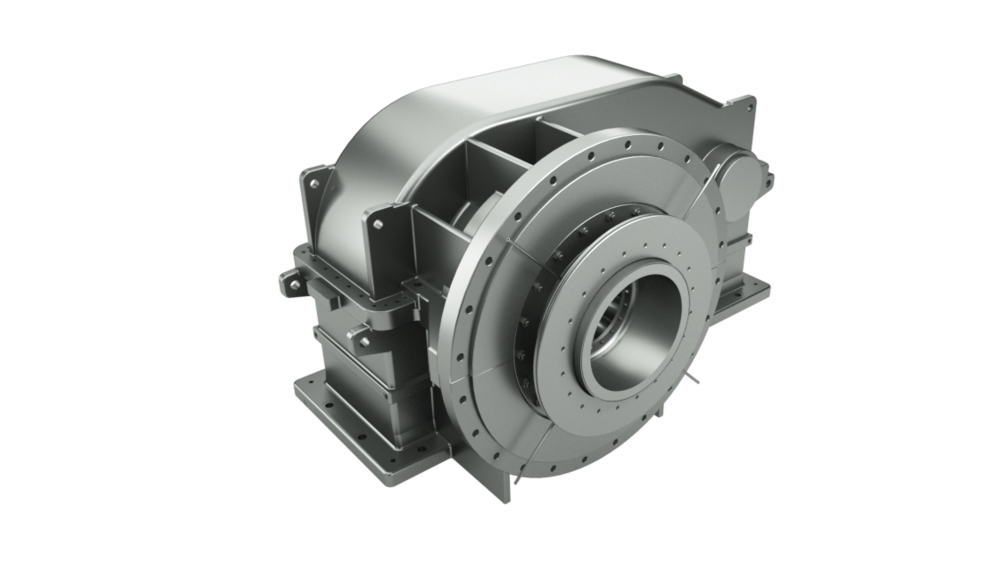

- UNOREX: a specially developed spur gearbox for single-screw extruders that is equipped with an integrated lubricating oil system. It can be flexibly adapted to any geometric requirement and is available with optional plain bearing technology or an explosion-proof design. It is technically on par with established competitors, with the decisive advantage that customer-specific adaptations can be implemented quickly and easily.

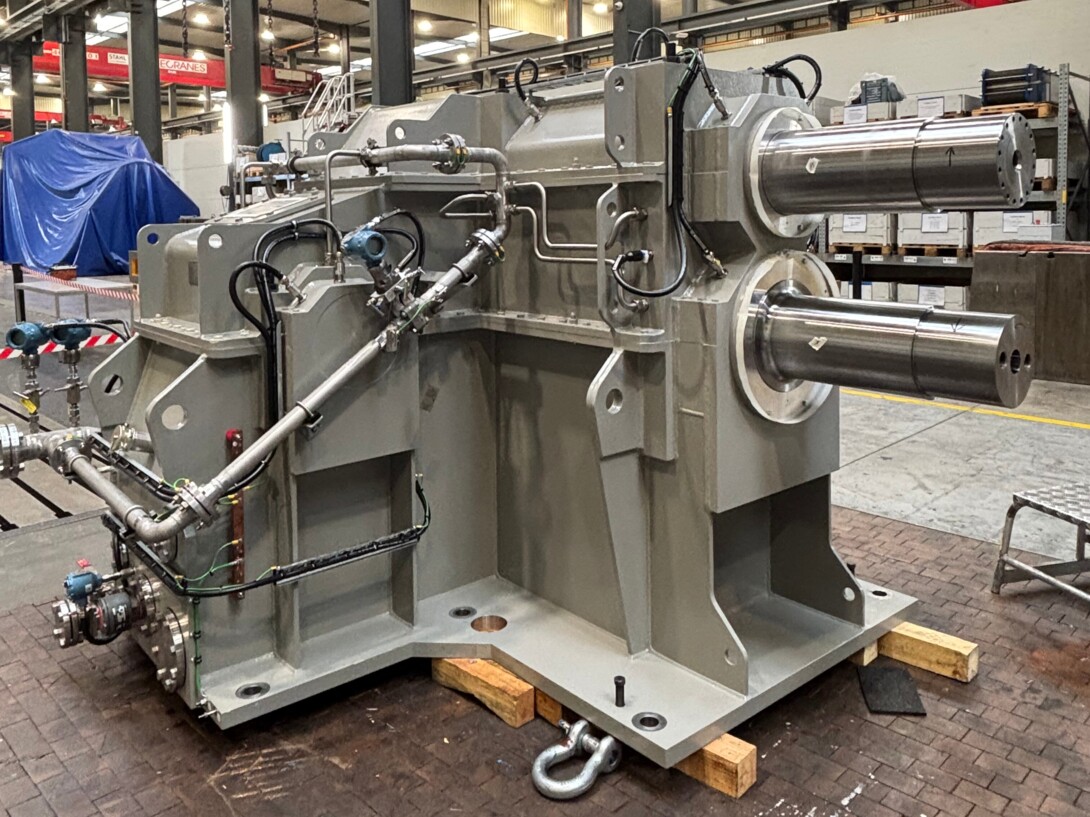

- MIREX: a custom replacement gearbox with innovative plain bearing technology for counter-rotating twin-shaft mixers (Farrel Pomini). It is equipped with an integrated lubricating oil system. This tailor-made, drop-in solution replaces standard roller bearings with sophisticated plain bearing technology, resulting in a significantly longer service life, reduced maintenance costs, and maximum efficiency. State-of-the-art gear technology ensures optimum performance and operational reliability.

Both projects prove that RENK is not only a leader in the field of large co-rotating twin-screw extruders — with more than 600 installations worldwide — but is also expanding its range to include new applications and markets.

How RENK reaches the customer: with technology, network, and trust

MIREX: Retrofit with future potential

Thanks to RENK’s global network, a need was identified early on in the replacement market for a potential new customer. The solution: a customized drop-in replacement for an existing competitor product – equipped with RENK sleeve bearing technology, which reduces operating costs over the entire life cycle thanks to its virtually unlimited service life. The result: higher operational reliability, reduced downtime and risk – and promising prospects for follow-up orders.

UNOREX: strategically important for series production

Thanks to RENK’s global network, a need was identified early on in the replacement market for a potential new customer. The solution: a customized drop-in replacement for an existing competitor product – equipped with RENK sleeve bearing technology, which reduces operating costs over the entire life cycle thanks to its virtually unlimited service life. The result: higher operational reliability, reduced downtime and risk – and promising prospects for follow-up orders.

Future mission: retrofit & awareness

With MIREX and UNOREX, RENK is purposefully expanding its portfolio, responding to specific market needs with retrofit solutions and customized technologies. This opens up new perspectives for both existing and potential customers. At the same time, RENK is sharpening its profile as a reliable partner for demanding extrusion applications. The goal: to provide operators worldwide with even more targeted information about technological alternatives and retrofit options – and to unlock new potential.

Ready for your questions!

Get in touch with our engineering experts to discuss your questions and how we can contribute to your project success.