MULTICOM® integral gear unit: reliable and efficient high-speed power transmission

- 01Broad application range

- 02Long lifetime, high MTBF

- 03Reduced power loss and emissions

- 04RENK in-house bearings

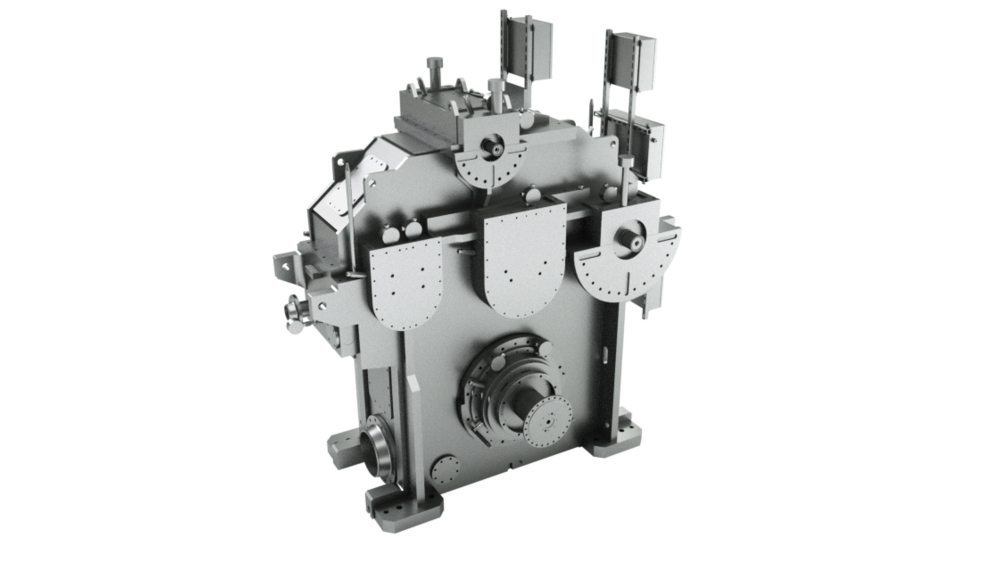

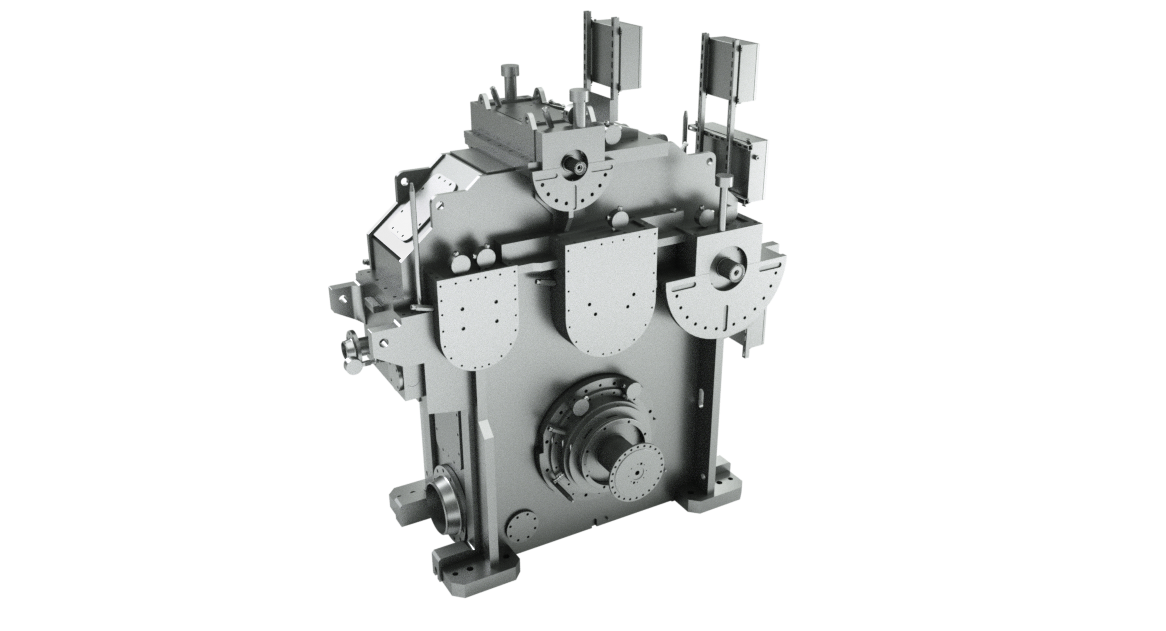

The MULTICOM® is a multi-shaft integral gear unit designed using the latest gear technology. This type is capable of driving up to 10 compressor or expander stages at five different speeds, making it a core component in various compressor systems. With efficiencies up to 99%, the MULTICOM® gearbox is a highly versatile and energy saving solution.

The integral gear unit is the preferred choice for a wide range of industrial applications requiring high speed, multi-stage compression and power transfer. The MULTICOM® can be found in industries such as air separation, chemical and petrochemical, LNG, and new applications like Energy Storage, Hydrogen, Heat Pump, CCUS (Carbon Capture, Utilization and Storage) and other process industries as further described below.

Integral gearbox with a wide range of applications

Technical specifications of MULTICOM® gear units include a power transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. range of 0.25-50 MW, speeds up to 63,000 rpm, ratios up to 30, and the ability to accommodate 1 to 10 compressor stages. The casing is of welded or cast-iron construction and the gearing is single helical with a thrust collar or thrust bearing.

Available drives include synchronous and asynchronous electric motors, gas turbines, steam turbines and expander turbines.

Integral gearboxes are widely used in critical industries such as air separation – nitrogen (N₂) and oxygen (O₂) –, carbon dioxide (CO₂) and liquefied natural gas (LNG), and PTA (Purified Terephthalic Acid) market. RENK's MULTICOM® gear units play a key role in these applications by providing precise control of rotating components, ensuring efficient power transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. and optimum performance. Furthermore, in the field of new energies such as hydrogen (H₂) compression, energy storage, heat pumps, carbon capture, utilization and storage (CCUS) or in the production of various gases, our integral gear units are essential for maintaining process efficiency and reliability in these vital sectors.

High MTBF and reliability with minimal unplanned downtime

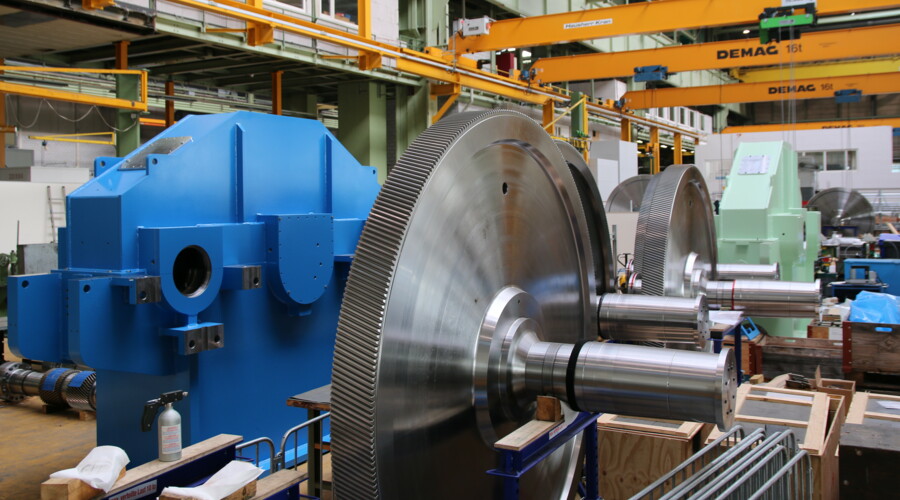

RENK-MAAG has been an expert in heavy-duty gear technology for more than 150 years. And our MULTICOM® integral gear unit is a masterpiece of engineering and manufacturing excellence. The impeller of our customer is via Hirth toothing directly connected to our pinions, which are designed and manufactured to the highest precision, resulting in low friction, low power loss and long service life.

The gearbox itself is an integral part of the compressor system, absorbing both static and dynamic forces from the compressor volutes and piping. Special seals are used to prevent oil from leaking from the gear casing.

All with a focus on maximizing uptime and durability to increase our customers' productivity.

Higher efficiency for lower emissions

Thanks to RENK-MAAG's experience and manufacturing expertise, the high-quality gears and toothings have the lowest power losses. This results in lower energy consumption and therefore lower emissions.

In addition, an energy recovery system can be implemented in combination with a synchronous clutch. In this setup, a electric motor could drive an integrated compressor gearbox, while an integrated expander gearbox can be switched on automatically via a RENK synchronous clutch if required and returns process energy to the system.

In case operators want to increase the efficiency to a maximum level, the integral gear unit can be equipped with a booster cover. This gearset cover is an inner housing, which reduces the power losses due to less windages.

Enhance industrial performance with our advanced slide bearings

RENK slide bearings Slide bearings Slide bearings facilitate the low-friction movement of shafts by coming into direct contact with a sliding surface. are designed for superior efficiency and durability.

In particular, RENK radial tilting pad bearings installed in our MULTICOM® integral gearbox optimize operating performance and reliability. This combination enables precision in high-speed applications and provides a robust solution for industries requiring reliable power transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. systems. Together, they provide a complete drive solution that improves the energy efficiency, reduces maintenance and extends the life of a compressor or expander machine train, making it ideal for demanding industrial applications.

Combined with our proprietary radial tilting pad bearings, the MULTICOM® gear unit provides a highly efficient and durable solution for your power transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. systems.

Take a look at our extensive slide bearing portfolio.

Technical Data

| Power transmission: | 0.25–50 MW |

| Efficiency: | Up to 99% |

| Speeds: | Up to 63,000 rpm |

| Gear ratios: | 1–30 |

| Number of compressor stages: | 1–10 |

| Casing construction: | Welded and casted |

| Toothing: | Single helical with thrust collar or thrust bearing |

| Driving variants: | Synchronous electric motor, asynchronous electric motor, gas turbine, steam turbine, expander turbine |

Adapting integral gearboxes to your operational requirements is our profession.

Our MULTICOM® gear units are customized and designed according to the latest findings and methods in gear technology and optimized for your application and requirements.

Get in touch with our experts if you have any questions.