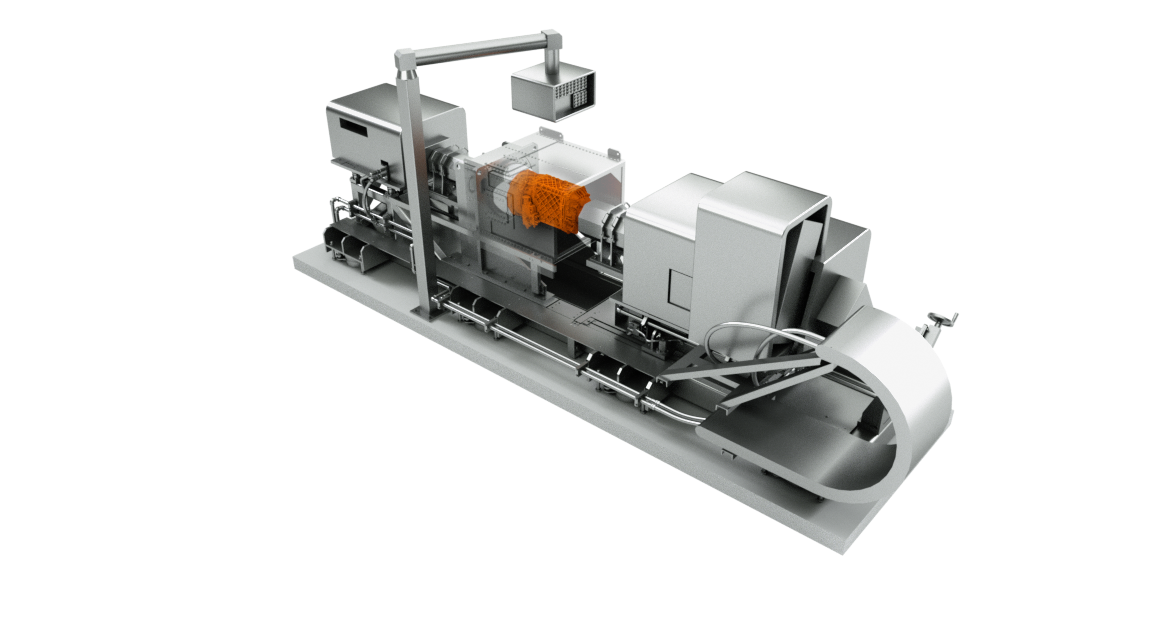

Gearbox test rigs

- 01Exact simulation of weight and driving loads

- 02Combustion engine or AC motor upon request

- 03Customized pallet system

Our technologies for your demands

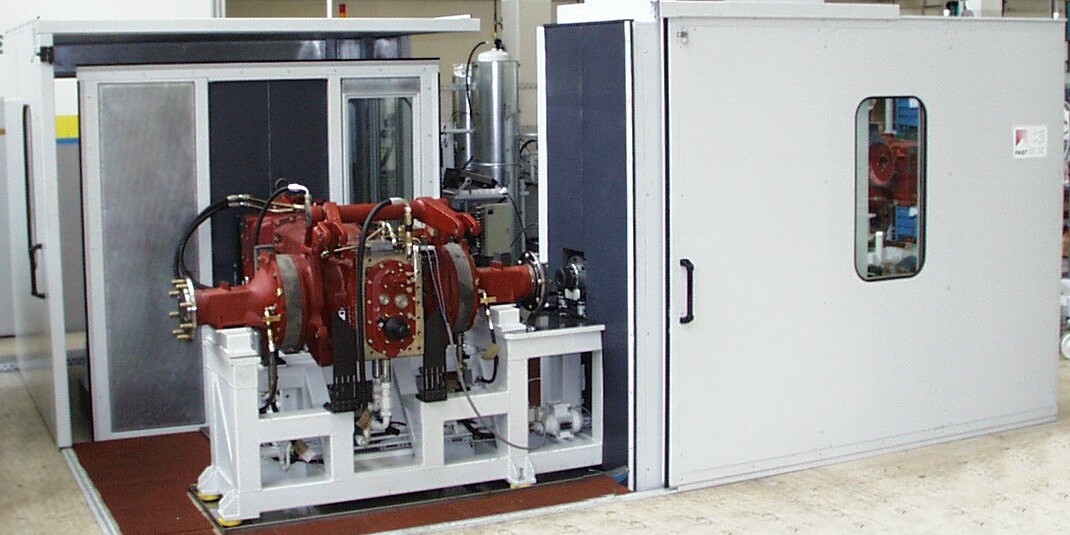

RENK offers individual transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. test rigs at the highest level for the development and quality assurance of heavy-duty vehicles, from trucks up to agricultural equipment.

Due to different tasks of the gearbox as well as driving profiles of the vehicle, there are different load requirements in the test bench.

For example:

- Static and dynamic torques and speeds

- Torsional vibrations of an internal combustion engine

- Driving dynamics

- Tilts and inclinations

- Environmental conditions

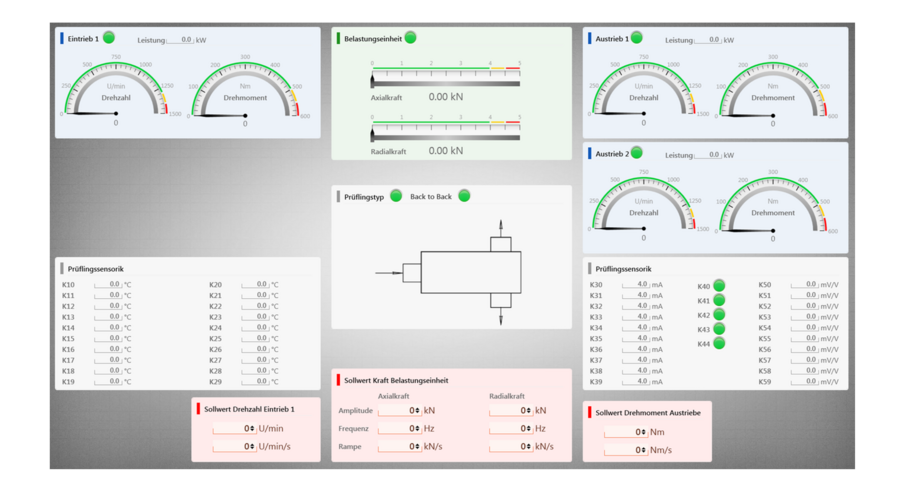

Gearshifts of the transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. to be tested are controlled via its mechanical and electrical interfaces in order to simulate real driving loads. With our RENK RDDS test bench automation system, predefined test runs can be processed unmanned and fully automated or individual test points can be tested in manual mode.

Our product range includes manual and automatic gearboxes for wheeled vehicles, fully automatic transmissions Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. for tracked vehicles Tracked vehicles A tracked vehicle is a vehicle that moves on tracks rather than wheels, typically used for rough terrain. and all types of power take-offs (PTOs).

In cooperation with the customer, the appropriate test bench concept is created depending on the transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. load and the purpose of the test bench (development support, quality assurance in production or maintenance).

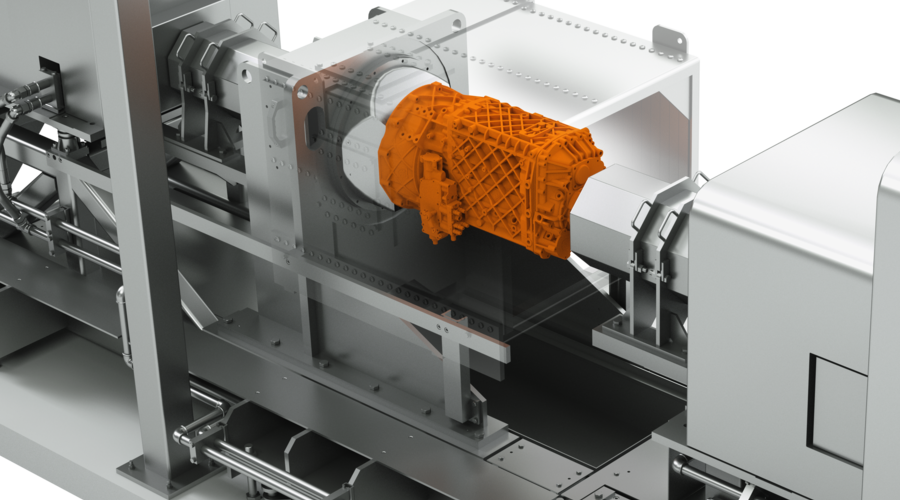

Exact simulation of the vehicle weight and driving loads occurring during operation

Gear units for heavy vehicles must perform absolutely reliably under special loads. For this reason, it is indispensable to simulate these loads realistically and reproducibly on the test rig. A perfect interaction of drive systems, measurement technology and test bench automation enables RENK gearbox test benches to simulate all desired driving conditions in the best possible way.

Drive unit as a combustion engine or AC motor with simulation of combustion engine dynamics upon request

Highly dynamic speed variations of an combustion engine are a very important design criterion for the mounted gearbox in conventional drive trains. However, by using state-of-the-art electric drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles. and specially developed control algorithms, it is also possible to exactly reproduce the characteristic curve of an combustion engine, including the speed variations. Simulation of real loads without the disadvantages of an internal combustion engine in test rig use. With our gearbox test benches, the customer can thus determine the type of drive system according to his own requirements.

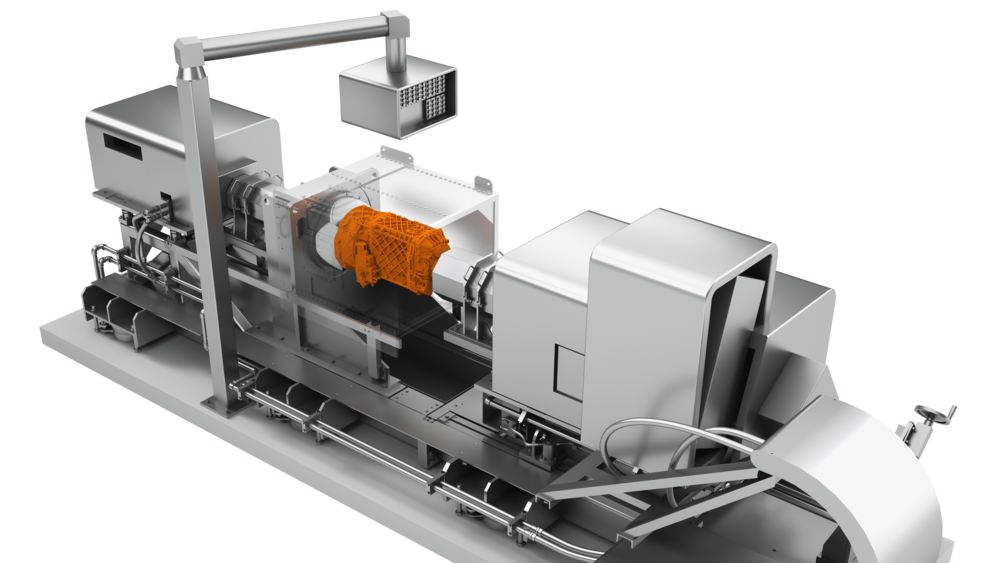

Customized pallet system for fast test specimen replacement

Our test benches are generally modular in design and can be used for different transmissions Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. with the appropriate adapter sets. We have developed a special pallet system for the test specimen mounting, which is precisely adapted to the customer's product range.

Features

- Modular design taking into account the specific requirements of the customer

- Test bench drive optionally electric or original combustion engine

- Realistic simulation of all driving conditions

- Pallet system for quick change of test specimen

- RENK RDDS test bench automation and data acquisition

- Applicable in development support, quality assurance in production or maintenance

Get in touch with our experts

in case of any questions.