Function chassis dyno (EoL)

- 01“True Turnkey” service

- 02Modular and expandable

- 03Unique compact design

Our technologies for your demands

Chassis dynamometers with double rollers are used for final checks and quality testing in the series production end-of-line (EoL) of multi-axle heavy vehicles:

- Function tests

- Quality checks

- Tachograph calibration

- Noise tests

- Brake tests

- Emission measurement

- Leakage tests

- Loading checks

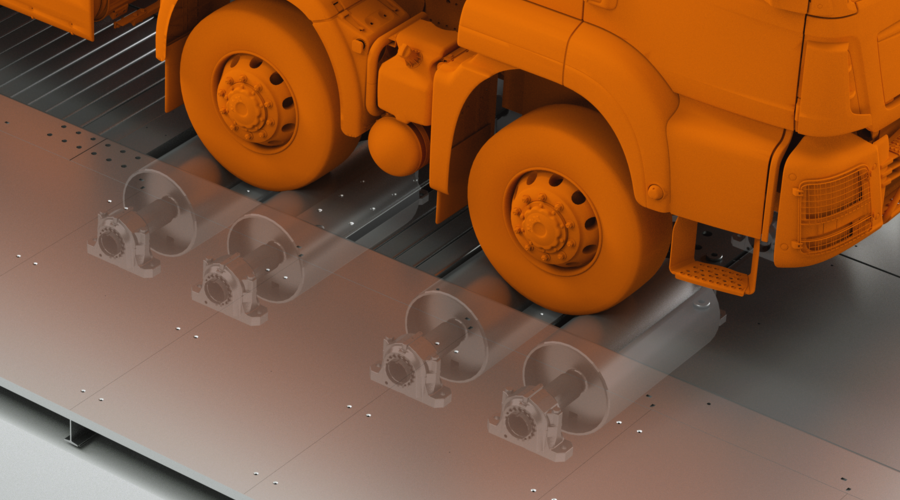

The double rollers are combined in independent roller units per axle. The number of roller units is selected taking into account the customer's entire vehicle range. The distance between the roller units can be moved electrically and thus individually adjusted to the wheelbase of each vehicle.

The multifunctional test stand setup for testing front, rear- and all-wheel-drive military vehicles under load offers a high degree of flexibility in carrying out everything from simple driving tests to special functional tests of, for example, TCS or differential lock functions.

Due to a special design of the roller units, they are extremely flat, which considerably simplifies the structural measures on the building to integrate the test stand.

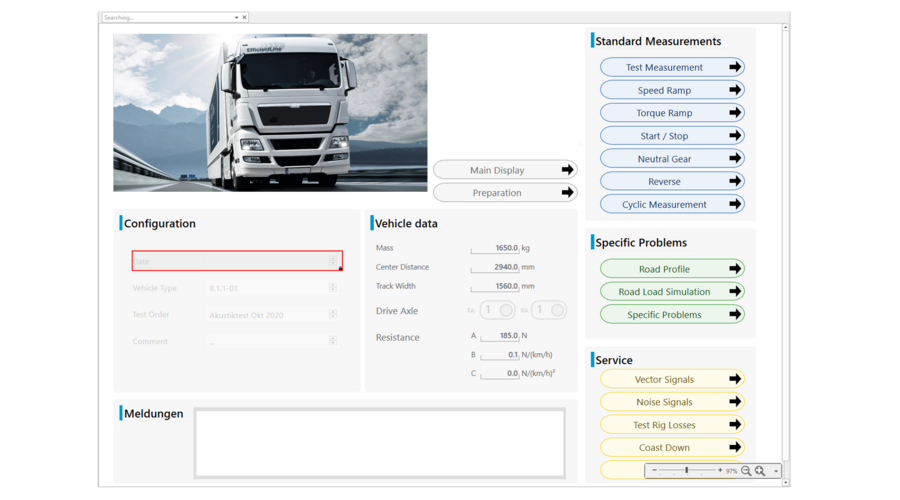

The RENK RDDS test stand automation system can manage all common test programs as well as self-assembled test runs.

If requested, an additional brake test stand can be integrated into the production line before or after the multi-axle function test stand.

“True Turnkey” service exactly according to customer needs

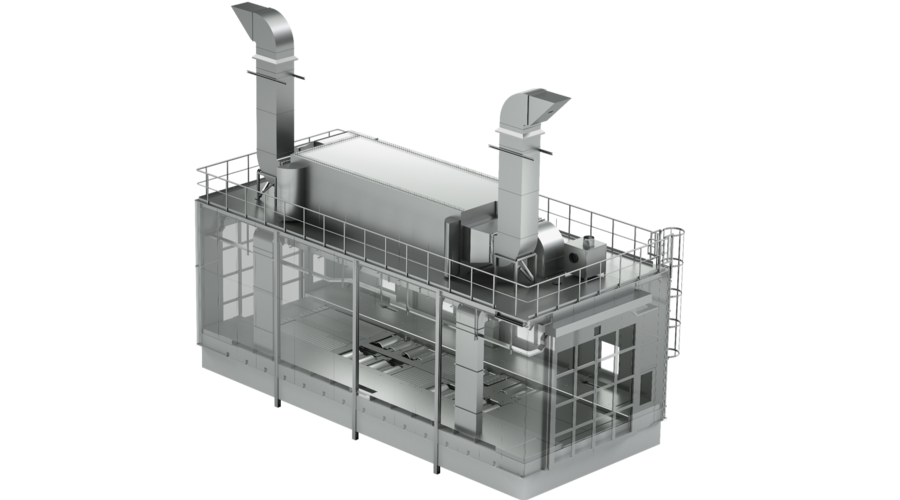

Depending on their intended use, complete vehicle test stands also require extensive infrastructure on the building side (foundations, test chambers, exhaust and air-conditioning technology, power and media supply, etc.). In addition, a wide range of measurement equipment has to be integrated and automated test runs created. For us, "true turnkey" means clarifying with the customer all the necessities of his test stand project and processing an optimum scope of services for the customer. From the basement to the roof. From planning to implementation.

Modular and expandable test system for a wide range of testing tasks

The change of test requirements goes in line with the further development of the vehicles. For this reason, complete vehicle test stands, which are usually operated for decades, must have a very high flexibility. The adaptation of new specimens or the modification of test programs can be carried out by the operators of our test benches themselves. For more extensive adaptations, our experienced service team is at your disposal.

Unique compact design

Through constant exchange of experience with our customers and continuous further development of our drive solutions, we can offer uniquely compact vehicle test benches today. Our test stands require the minimal amount of ground work in their performance range. For this reason, our test stands are also perfectly suited for retrofitting in existing buildings. And in new buildings, too, less ground work naturally means lower costs.

Features

- Function Chassis Dyno for final checks and quality testing in the series production end-of-line (EoL) of multi-axle heavy vehicles.

- Customized total solutions for the entire required performance range

- High modularity

- State-of-the-art drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles.

- High reliability and durability

- RENK RDDS test bench automation and data acquisition

Get in touch with our experts

in case of any questions.