Together from idea to reality

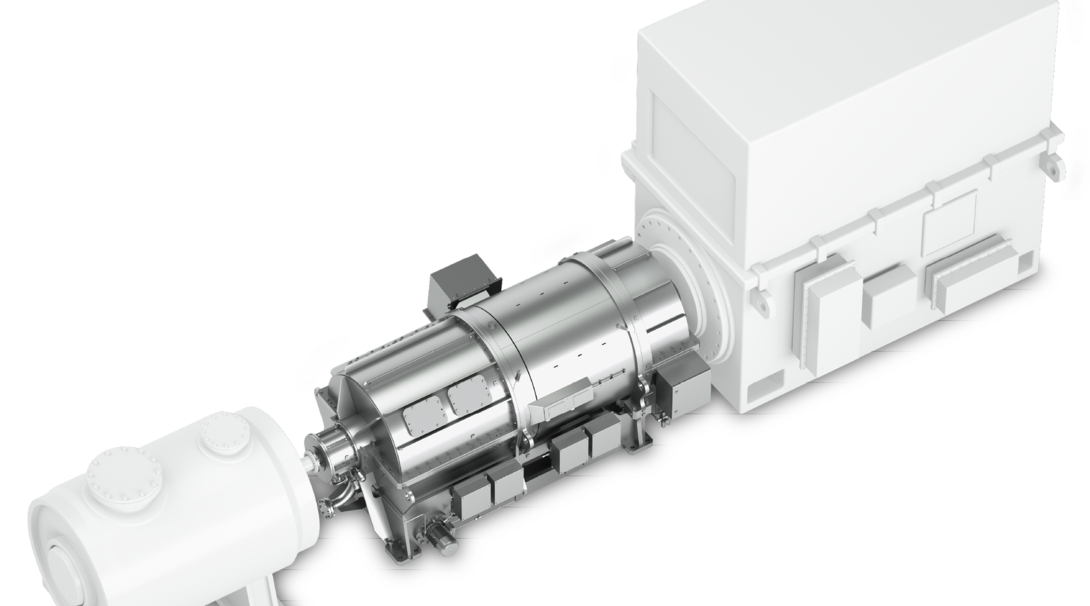

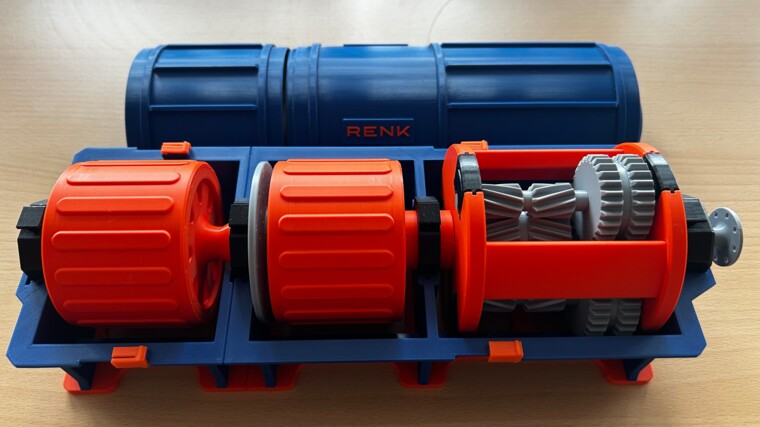

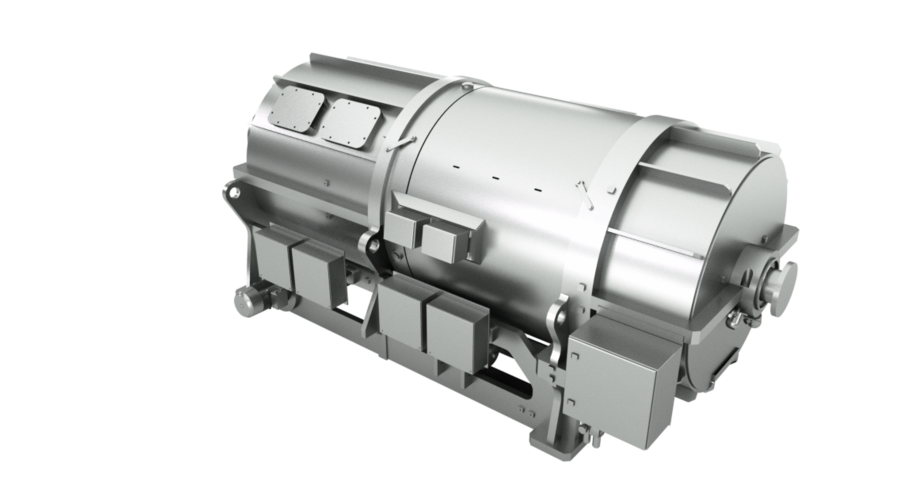

It is often easier to understand a concept if you can not only see but touch it. With the 3D-printed model of our RECOVAR®-E gearbox, this became a reality. Said and done: born from a simple idea, the data was prepared within a few weeks and just a short time later a 3D-printed model was created – composed of several precisely printed parts.

Since then, the model has been part of numerous customer meetings around the world. Customers are thrilled to hold the model in their own hands, as it makes the complex mechanisms of the transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. much more tangible and understandable.

3D-printed RECOVAR®-E model enhances cross-site collaboration

Internally, the model offers advantages for the cross-location work of the RECOVAR®-E team: While the RECOVAR®-E gearbox is managed, developed and produced in Augsburg, the product manager for high-speed and the turbo engineering manager are based at the RENK site in Winterthur (CH). There, the 3D model of the gearbox has already been presented to many of our colleagues. Furthermore, it has been used for training purposes and has thus already created more proximity to the finished product.

Not only is the 3D-printed model a technical highlight, but an inspiring example of the extraordinary commitment of our employees.

Ready for your questions!

Get in touch with our engineering experts to discuss your questions and how we can contribute to your project success.