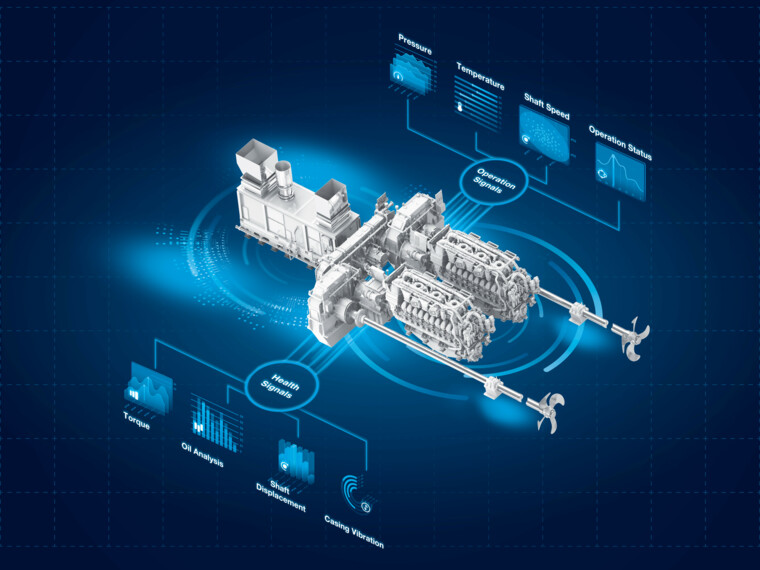

The failure of an element of the propulsion system is usually "announced" by an increase in temperature, vibration, noise, strain, etc. With a condition monitoring system, these early warning messages can not only be detected far in advance, but also analyzed to determine the problem and the root cause.

With this given transparency and reporting the operators can plan maintenance and repair activities aligned to the shipping and mission schedule.

The benefits of condition monitoring for vessels

There are various benefits of a condition monitoring systems and the importance of each may differ dramatically whether you are responsible for a yacht, cargo vessel, tanker or a navy ship.

By continuously monitoring the condition of critical equipment onboard a ship or vessel, such as engines, gears and pumps, condition monitoring systems can detect potential equipment malfunctions before they cause major problems. This allows for early intervention and preventive maintenance, reducing the risk of costly breakdowns and downtime. Thus, ensures meeting your shipping schedule or worldwide navy missions.

Condition monitoring Condition monitoring Condition monitoring involves continuously monitoring technical systems to detect deviations or damage early on. systems can help improve safety by identifying potential safety hazards, such as leaks, excessive vibration, or abnormal temperatures. Early detection of these issues can prevent accidents and injuries and ensure that the vessel and crew remain safe.

By identifying potential equipment failures before they occur, condition monitoring systems can reduce maintenance costs, prevent downtime, and extend the life of critical equipment. This can result in significant cost savings for ship and vessel owners and operators.

By monitoring equipment performance and identifying inefficiencies, condition monitoring systems can help optimize ship and vessel operations. This can result in improved fuel efficiency, reduced emissions, and increased profitability.

Overall, condition monitoring for ships is a valuable tool, providing early warning of potential equipment failures, improving safety, reducing costs and optimizing operations.

Onboard there are various systems in which condition monitoring can provide vital information.

Bearing and gearbox: Condition monitoring can detect bearing and gearbox faults, such as misalignment, wear, and fatigue, which can cause excessive vibration and lead to more severe problems.

Engines & drives: Condition monitoring can identify engine faults, such as cylinder wear, piston ring wear, and valve problems, which can lead to reduced efficiency, increased fuel consumption, and potential breakdowns.

Hydraulic system: Condition monitoring can observe hydraulic system, metal particles, blockages, and pressure drops, which can cause reduced performance and potential damage to equipment.

Electrical system: Condition monitoring can detect electrical system issues, such as insulation degradation, motor faults, and circuit board problems, which can lead to electrical failures and equipment damage.

Cooling system: Condition monitoring can detect issues with the cooling system, such as blockages, leaks, and temperature fluctuations, which can cause engine overheating and failure.

What are the components of a condition monitoring system for ships?

Basically, a CM system consists of a sensor array applied to the component which should be monitored. Those will be connected with a software and database which in best case can not only store and visualize the sensor information, but also has some intelligence embedded to analyze the data and bring it into an understandable context for the operator. Therefore, our recommendation what tasks should be done for establishing a CM system are:

- Define the failures options and what the early warning indicators are.

- Identify a software solution which can handle the application. Also check the feature set, ease of use and visualization, documentation and interface ability.

- Select the most efficient sensors with a fitting interface/bus and also how and where to apply them.

- Place sensors, cables and software system.

- If possible, run factory acceptance test before installing on the ship to avoid costly iterations.

- Carry out on-site commissioning, operator training and offshore acceptance testing.

- Pay attention to CM adaptation/fine tuning due to the individual behaviour of complex propulsion systems.

Those are not all but from our experience vital steps to define and implement a reliable CM system. And experience is a crucial aspect for a project success, that is why we highly recommend using external partners, as RENK or others, in case you do not have done a lot of those projects.

In case you have any question in regard to Condition Monitoring get in touch with our experts from the Digital Solutions business team.