Increasing societal affluence has a downside: Global warming. Industry, buildings, mobility and energy generation with fossil fuels are responsible for carbon dioxide (CO₂) emissions. Amplifying as it does the greenhouse effect, this gas contributes to the change in our global climate. To keep the situation from deteriorating further, at Paris in 2015 196 countries signed an accord calling for drastic reductions in CO₂ emissions. Decades will pass, however, before the biggest emitters can achieve climate-neutral operations. Right now, therefore, those technologies that are most promising for reducing CO₂ emissions take center stage.

RENK is one of the players involved in this mode of active climate protection. The company has a wealth of experience in the field of gas compression. "This is essential for capturing CO₂ and compressing it, for example for storage in sub-seabed geological formations or in spent natural-gas or oil fields", asserts Maximilian Billes, Executive Assistant in RENK's Marine & Industry Division. Decades ago, scientists established that when sequestered at a depth of 800 meters, CO₂ liquefies under high pressure and subsequently compounds with the surrounding rock. This process prevents the sequestered CO₂ from returning to the surface at some point in the future and affecting the global climate.

CCUS technology helps cutting CO₂ emissions

Carbon Capture, Usage and Storage – CCUS for short – is of particular relevance in those energy-intensive branches of industry that are unable to cut their CO₂ emissions. These include for example the production of lime, cement, numerous chemical substances and fuels. For fossil-fired power plants too (lignite and hard coal), this is a viable option for reducing high CO₂ emissions. CCUS technology has been used on an industrial scale off the coast of Norway since 1996. Other CO₂ storage sites are being planned all over the world. „For industry and utilities, the technology represents one way of crunching down their inherently high CO₂ footprints. That cuts outlay for the increasingly costly emissions certificates, as well as improving sustainability positioning", asserts Nadine Despineux, CEO of the Marine & Industry Division.

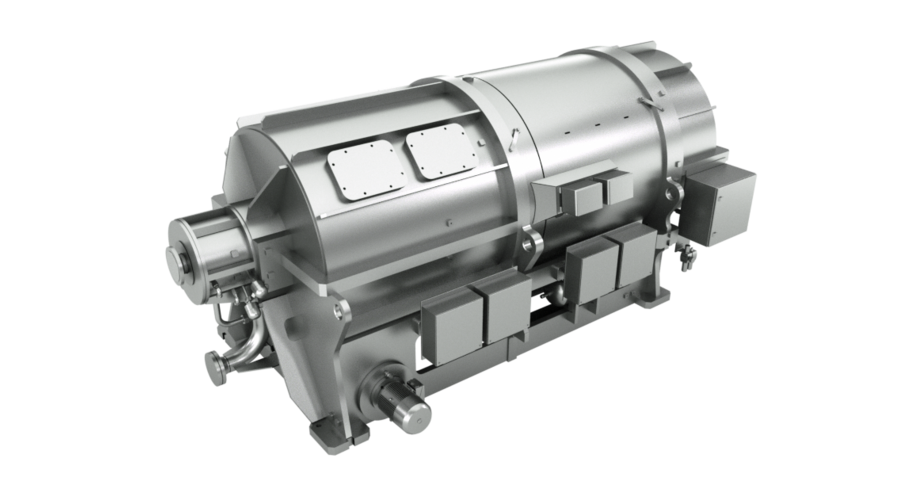

There are only a handful of companies worldwide able to meet the demand for the special compressors with high-performance gear units for carbon dioxide compression and sequestration in former oil and natural-gas fields or suitable rock strata. RENK has amassed decades of experience in this sector. The company is one of the world's big three manufacturers of turbo gear units. Pumping oil and natural gas is one of the fields in which these units are essential. They are used for compression to ready the commodities for transport through pipelines. Gear units and components for the compressors often have to be tailored to the needs of a given facility. This dovetails with RENK's principal strengths as provider, because the company views challenges of this nature as part of its core business.

Sequestration is one option, but CO₂ can also be utilized in special power plants, where compressors force the gas into high-pressure buffer storage. The gas can then be injected back into the original tank when needed, spinning a turbine to generate electricity. "In much the same way as water in a pumped storage hydroelectric plant, CO₂ is compressed using surplus energy to produce a reserve that can be utilized on demand", explains Ms Despineux. RENK is a partner in a test facility to refine this technology on the island of Sicily.

200 compressors stations needed

Its experience gained in the oil and gas industry makes RENK a key player in the development of the hydrogen economy. As in other sectors, the gas has to be highly compressed for transport and post-transport usage. The fuel is then ready to be piped, or transported in special tanks, from point of origin to point of utilization. Like other products, hydrogen has to be compressed at various stages along the chain of use. "We are growing out of fossil fuels and into new energy sources", asserts RENK CEO Susanne Wiegand when she describes how the company sets about utilizing transformation in the energy sector as a market opportunity.

Broadly speaking, it would be possible to pipe hydrogen through the existing network of gas pipelines. This would entail upgrading the present infrastructure, however. In the European Union alone, planning envisages an additional 21,000 kilometers of piping. In all, more than 200 compressor stations will be needed to transport the hydrogen through the network built in this way. "This underscores the significance that attaches to the hydrogen economy", says RENK Innovations Manager Raphael Leibl. A range of gear-unit solutions is one way in which RENK could contribute to the sustainable expansion of the pipeline infrastructure.

The European Commission's "REPower EU" strategy aims at producing one million metric tons of renewable hydrogen in 2024 and ambitions ten million tons by 2030. Electrolysis capacity will be boosted from six to 40 gigawatts and by the end of the decade a European hydrogen market will have been established.

The EU has earmarked 50 billion euros for investment in this technology. Worldwide at this time there are more than 220 large-scale projects involving hydrogen ongoing. In the period up to 2030 more than 300 billion US dollars will have been invested in the sector. It is RENK's intention to be part of this hydrogen-economy growth market, which is expected to grow in volume to 85 billion euros in Europe alone by the end of this decade.

Providers are focusing primarily on energy-intensive industry sectors and on big utility companies as clients. They, in turn, are seeking alternatives that will prove as climate-neutral as possible in the long run. For example, RENK is working with a big German steel manufacturer to develop solutions for the use of hydrogen in production.

That would enable our technology to make an important contribution to the active reduction of CO₂ by up to 95 percent.

Transport and storage of hydrogen

RENK technology is also involved in the production, transport and storage of hydrogen. The company meets demand here with special compressors and various gear-unit solutions that plant manufacturers integrate into their systems. "This is where our expertise for custom-built high-performance components comes to the fore", emphasizes Thomas Fritschi, Head of Speed Solutions at RENK.

All in all, RENK is already well positioned in this still young market and is ready and able to utilize the continuously increasing dynamic to engender more growth. This also holds true for solutions associated with hydrogen production. The big picture here calls for utilization of the waste process heat from electrolysis. RENK gear units compress the heated water to produce steam so that the process heat can be tapped.

In the interim until clean hydrogen is available in sufficient quantities, natural gas can be used in production of the fuel. CCUS would circumvent the CO₂ freighting that would otherwise strain the environment. Hydrogen combines with nitrogen to form ammonia (NH₃). Various steps in the production process require the use of compressors for which RENK offers a range of planetary, spur-gear, integral and variable-speed gear units. At minus 33 degrees Celsius, the gas with the pungent odor is much easier to transport than comparable liquefied hydrogen, which has to be cooled to minus 253 degrees. At this time, 20 million metric tons are regularly transported by sea.

Hydrogen, moreover, is a basic building block for what are commonly referred to as e-fuels, the electro-fuels that are an alternative to petrol and diesel. Hydrogen together with CO₂ stored or captured from the atmosphere produces first methanol, which can then be reprocessed to produce a synthetic fuel. Millions of vehicles already on the roads can run on this fuel and be climate-neutral in further operation. In this sector too, RENK will be a force behind the development of methods appropriate for volume production. The crunch factor is that the hydrogen must come from renewable energy sources. Wind farms, onshore and offshore, are becoming increasingly important in this scenario. Many of these turbines are verified on test benches from RENK as a preliminary to going into service. So gear units and bearings from Augsburg help ensure many years of maintenance-free operation in the field.

Get in touch with our correspondent if you have further questions.