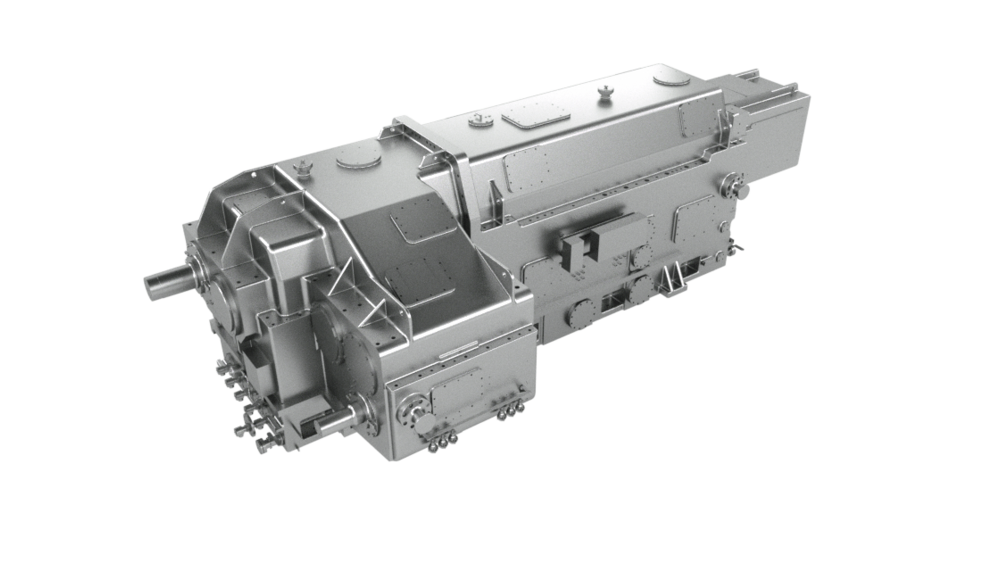

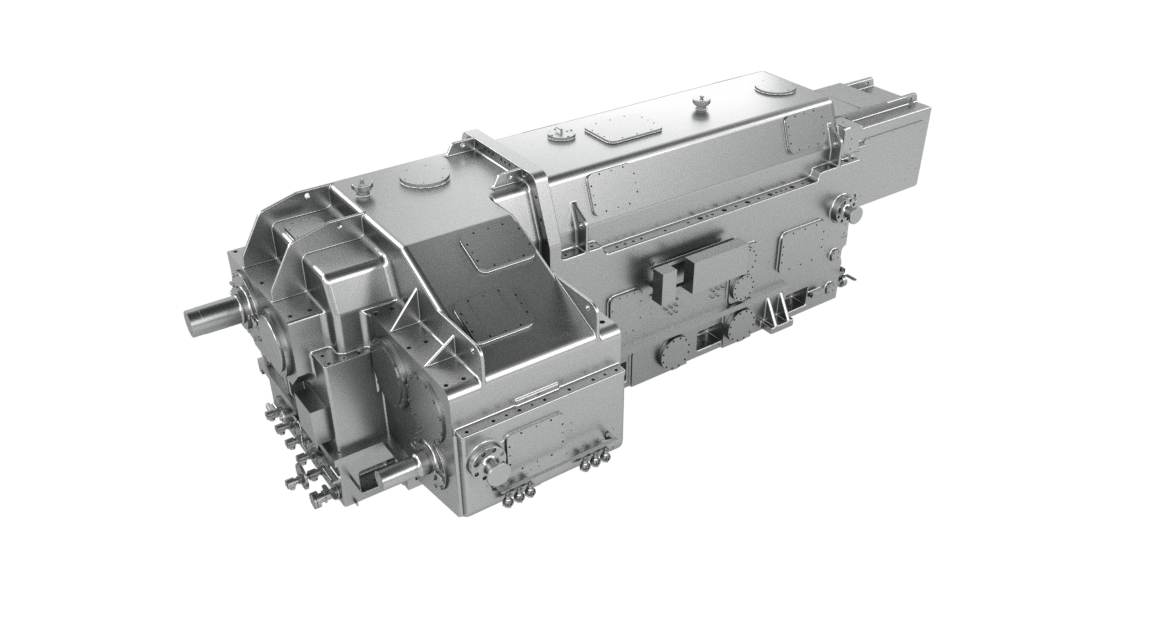

SUPREX twin screw extruder gear unit

The SUPREX extruder gear box is the most sophisticated solution for a variable-speed drive of large, twin screw extruders for polyolefin compounding.

Introduced in 1999, the SUPREX gear box’s integrated planetary superimposition gear stage enables variable-speed in an energy-efficient, cost-effective, and obsolescence-proof way. It combines a large, fixed-speed main motor (DOL) with a smaller, variable-speed drive (VDS) with frequency converter.

The gearbox is available with an output torque of up to 500 kNm per output shaft in both sleeve and roller bearing version with a flexible center distance and distinguishes itself due to a very high level of reliability and durability.

The sleeve bearing design in particular allows for maintenance intervals of > 10 years, thereby achieving the lowest maintenance costs and preventing expensive system downtime.

Features

- Variable speed for different material grades with high product quality in the compounding of polyolefines (polyethylene and polypropylene)

- 2.5% better overall system efficiency compared to large VSD + fixed-speed gear boxes – most economical solution

- Fewer obsolescence issues due to off-the-shelf frequency converter for small VFD

- Maintenance intervals > 10 years possible with the slide bearing Slide bearings Slide bearings facilitate the low-friction movement of shafts by coming into direct contact with a sliding surface. option

Technical Data

| Sense of rotation output shafts: | Co-rotating |

| Center distances: | From 205 mm to 349 mm |

| Output torques: | From 100 kNm to 500 kNm per output |

| Gear ratios: | From 5 to 14 |

| Input speed: | 1,200/1,500 or 1,800 rpm. |

| Gearing design according to DIN/AGMA: | Sleeve bearing or roller bearing version available |

Get in touch with our experts in case of any questions.