IFPS® – the smarter shaft generator

- 01Less space and easy to install

- 02Rugged design and easy to maintain

- 03Highest efficiency to reduce fuel consumption

- 04Easy to retrofit

- 05Approved by MAN ES and WinGD

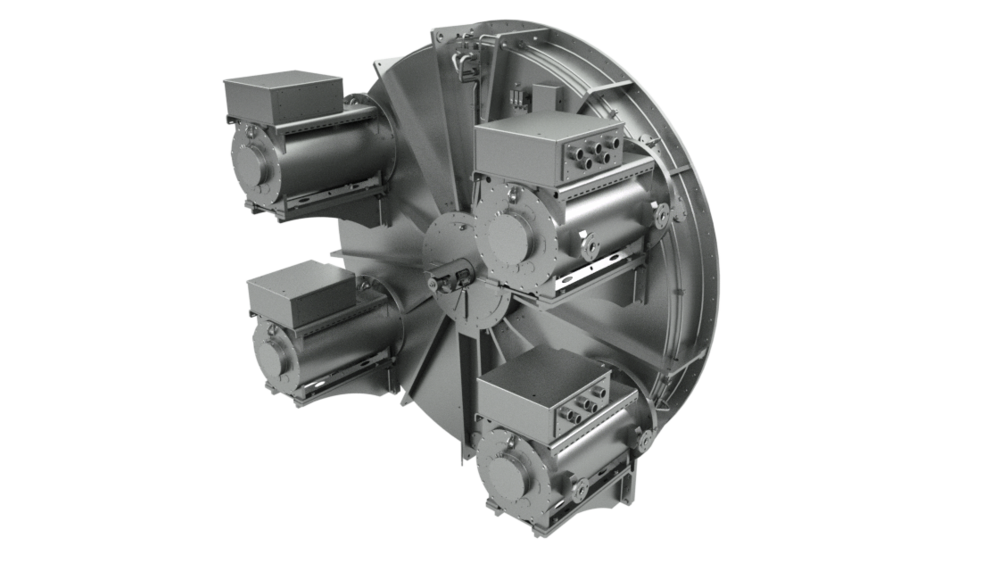

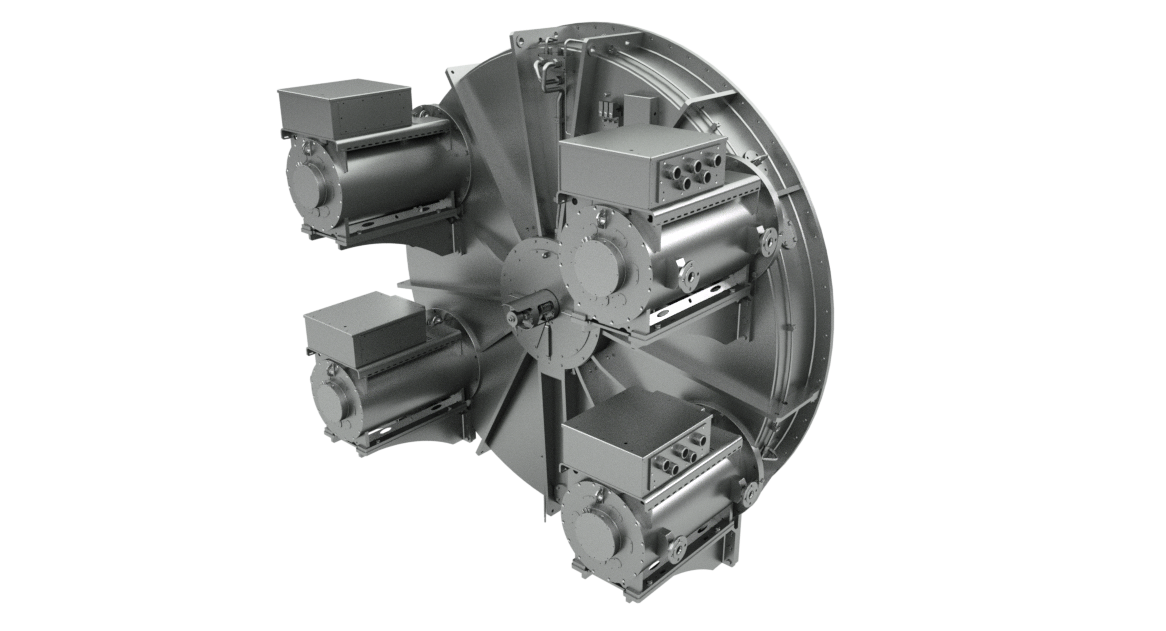

The front-end shaft generator offers various advantages due to the compact and modular design

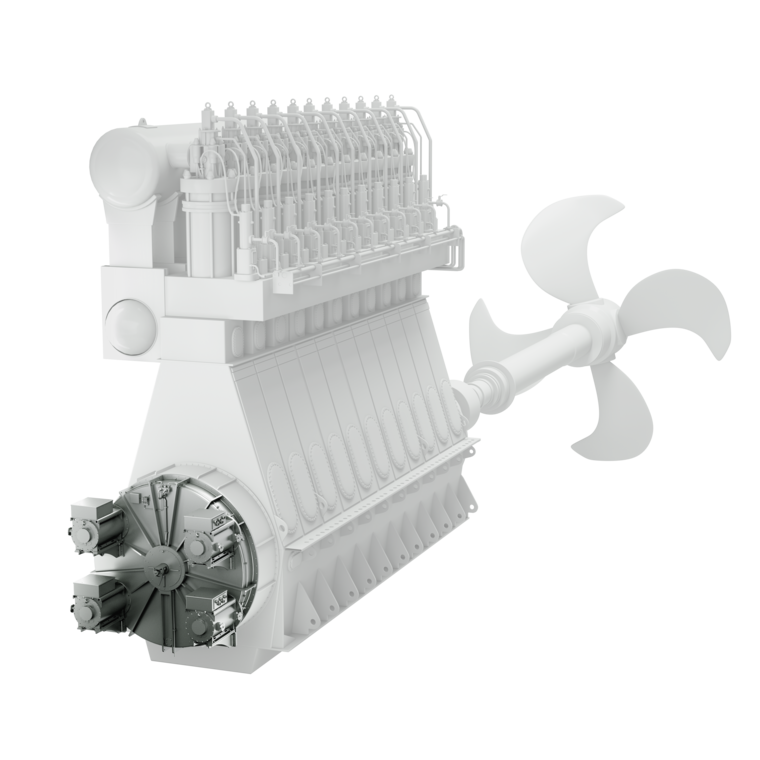

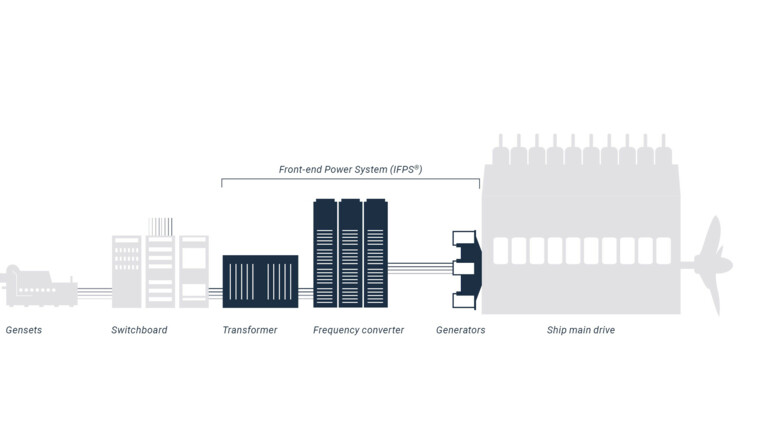

Most PTO generators are mounted on the propeller shaft. As this poses various challenges, the RENK engineers reinvented the shaft generator and went front-end. As a result, the IFPS® PTO generator is directly mounted to the main engine and connected to the crankshaft.

The ingenious design of the IFPS® (Integrated Front-End Power System) generator offers numerous advantages and is approved by MAN ES and WinGD. Some of the benefits are a smaller footprint, easy installation for new and existing ships, good maintenance and highest degree of efficiency.

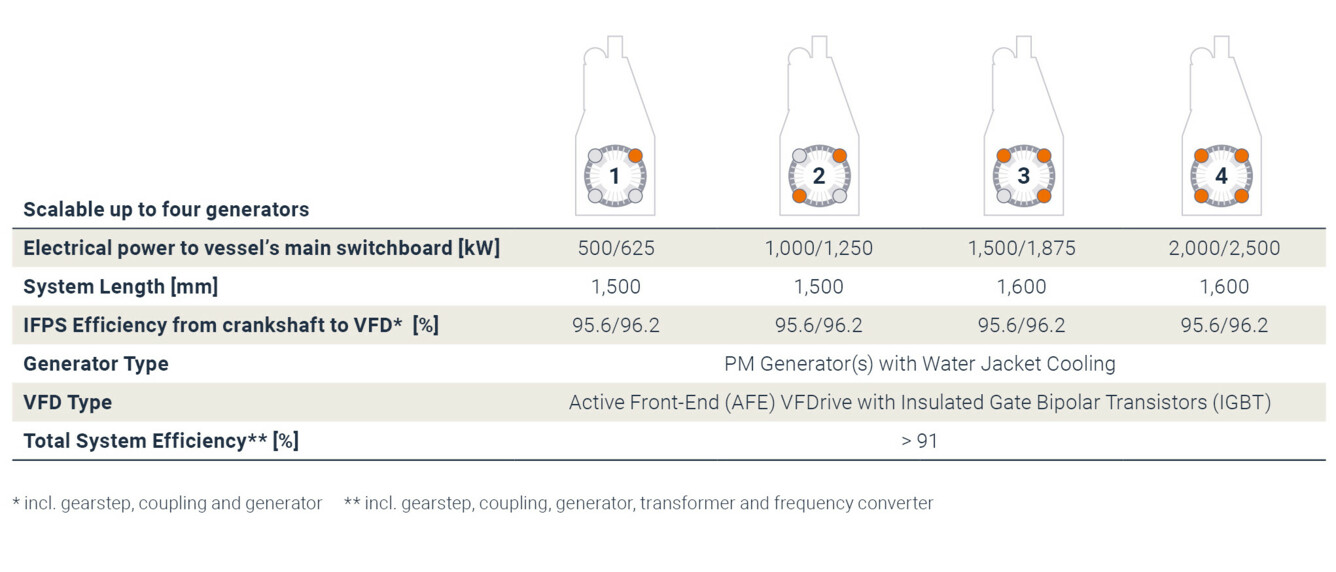

All this makes the IFPS® front-end shaft generator the preferred choice for vessels with a demand of up to 2500 kW electric power.

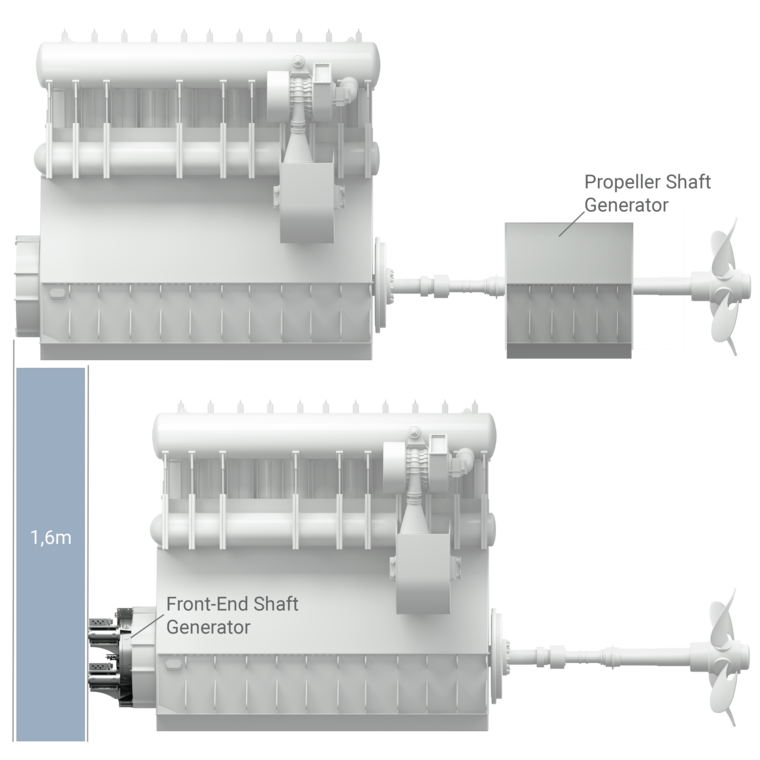

Save 1.6m and avoid elaborate installation in the ship

The IFPS® has some unique advantages for new vessels. It has a much smaller footprint than shaft generators and is mounted directly on the main engine.

While shaft generators typically require 4 frame widths, the IFPS® requires only 2, allowing the main engine to be positioned further aft. Usually this results in a gain of 1.6 meters.

As the generator is directly flanged to the front-end of the main engine, various benefits materialize. For instance, the need for a foundation is eliminated and it reduces the effort for the shaft alignment and overall system installation costs.

The modular and proven design guarantees highest uptime and is easy to maintain

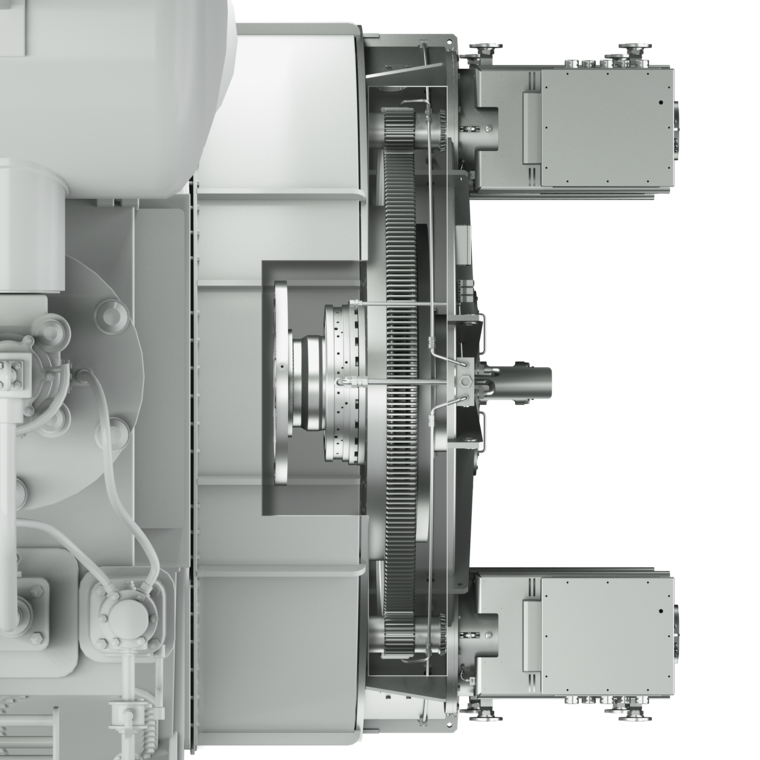

The modular design of the IFPS® is straight forward and optimized for the marine environment. The vibrations of the engine are handled by a flexible coupling to which a single-stage gear in RENK quality is connected. Also the generators are extremely rugged due to the permanent magnets.

In case any servicing activity at a shaft generator is necessary, the system is easy to access through the front cover and the generators are small and lightweight. While one generator is checked or repair is needed, the other connected generators may continue to operate and supply power.

Generator degree of efficiency beyond 97%

Higher-quality shaft generators use permanent magnets to increase efficiency and robustness, as does the IFPS®. However, due to the front-end concept, the generator shaft is more than 20 times smaller. Hence this results in a significant reduced air gap between the stator and rotor, leading to a much higher efficiency.

A propeller shaft in commercial ships rotates at lower speeds and is affected by seaways and inhomogeneous propeller inflow, which is a challenge for generators. Good shaft generators start to work at best at 40 % SMCR power, but with limited efficiency.

As the IFPS® is directly connected to the crankshaft and by using a single-gear stage, the generators benefit from much higher RPMs. Firstly, this increases the general efficiency of the generator. Secondly, the IFPS® shows a much higher efficiency at 40% main engine power than other systems.

Due to the efficiency and the overall electrical concept with an optimized active front-end (AFE) frequency converter a clean sinusoidal current is delivered to the grid with extremely low THD and operation of the system in a stand-alone island mode is possible additionally to parallel operation together with gensets.

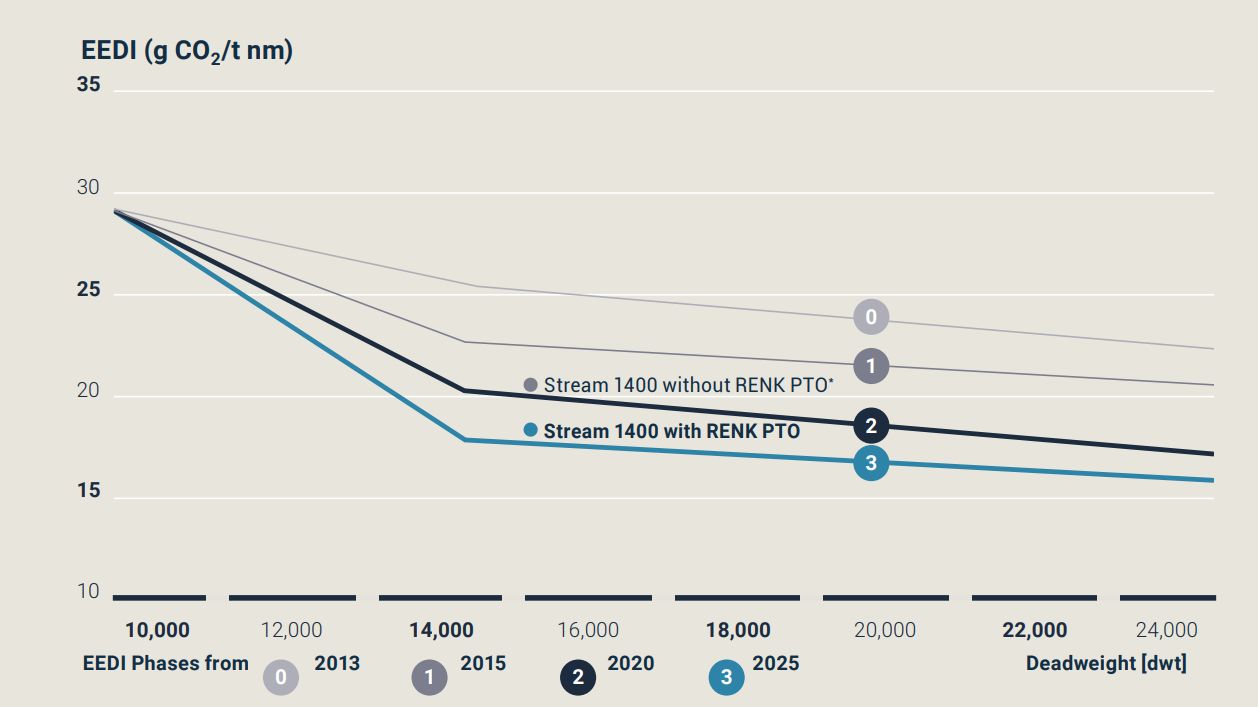

Strict IMO standards in the Energy Efficiency Design Index (EEDI) clearly regulate the often significant extent to which ships will have to boost their efficiency in every stage of their lifecycle.

Below you find a calculation done with Technolog Services. Get in touch with our experts to elaborate the EEDI impact for your specific project and ship.

The easiest way of retrofitting a ship with a shaft generator

A retrofit of a inline shaft generator for ships in operation is a huge project. Such generators are of considerable size and must be transported through the ship's walls into the engine room. After adjusting the propeller shaft and preparing the foundation, the shaft generator is installed.

With the IFPS®, works on the propeller shaft are eliminated and due to the compact size, the transport to and mounting in the engine room is a lot easier. Therefore the IFPS® is not only often the preferred but also only option to retrofit ships in operation with a shaft generator to contribute to EEXI regulations.

A complete package customized to your demands

The IFPS® is delivered as a complete package, covering the mechanical connection to the main engine, the gear unit including coupling, the generator package, a transformer and the frequency converter cabinet. RENK takes care from main engine to the main switchboard, so that you have full power available on-board.

Take a look at the different perspectives

- RENK Integrated Frond-end Power System (785 kB)

E-Mail angeben

Bitte geben Sie Ihre E-Mail-Adresse an, um den Download zu starten.

Get in touch with our experts in case of any questions.