Brake tester dynos (EoL)

- 01Customized

- 02Compatible

- 03Maintenance friendly

Our technologies for your demands

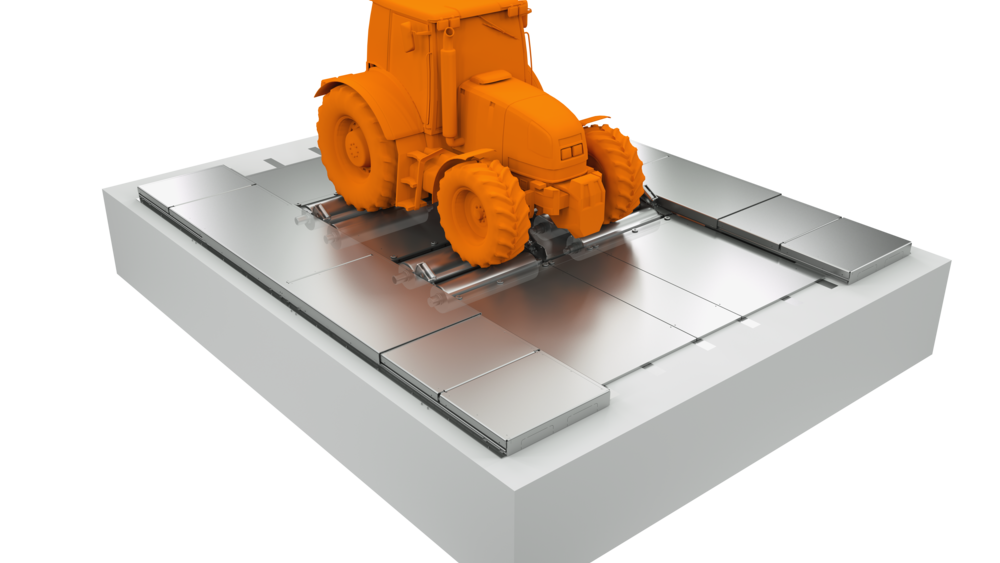

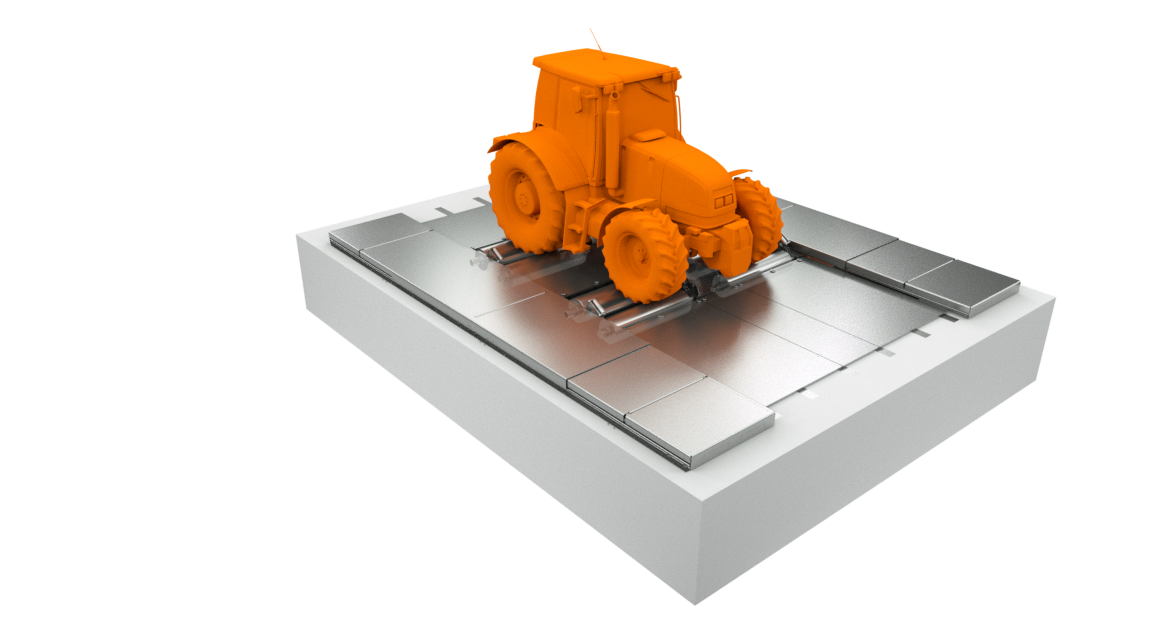

RENK brake tester dynos are particularly suitable in combination with RENK function chassis dynos in a test line at the end of production.

Measurement results from different test stands can thus be grouped and reported together.

Maintenance is simplified.

Special brake tests

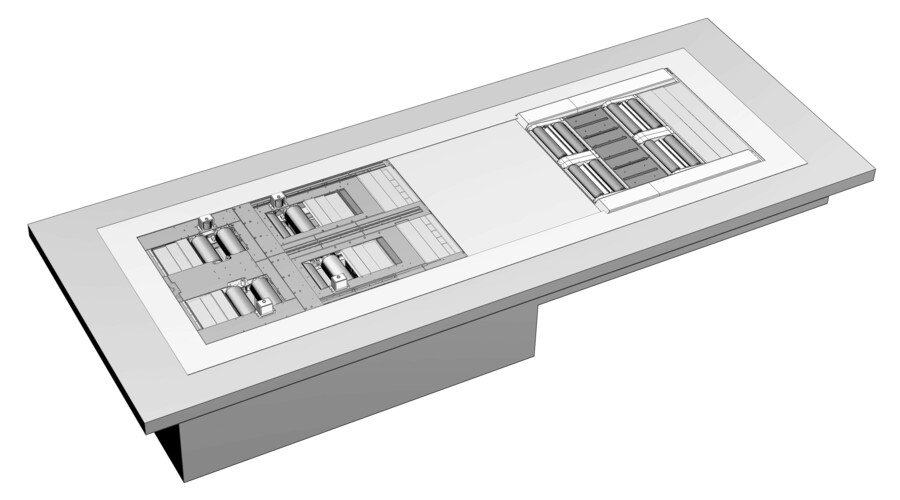

Since we generally do not have any off-the-shelf test rigs, our brake tester dynos are also tailored to the respective customer requirements. Therefore, in addition to standard tests, we can also fulfill all custom requests for special vehicles or special tests.

Team player in testing lines

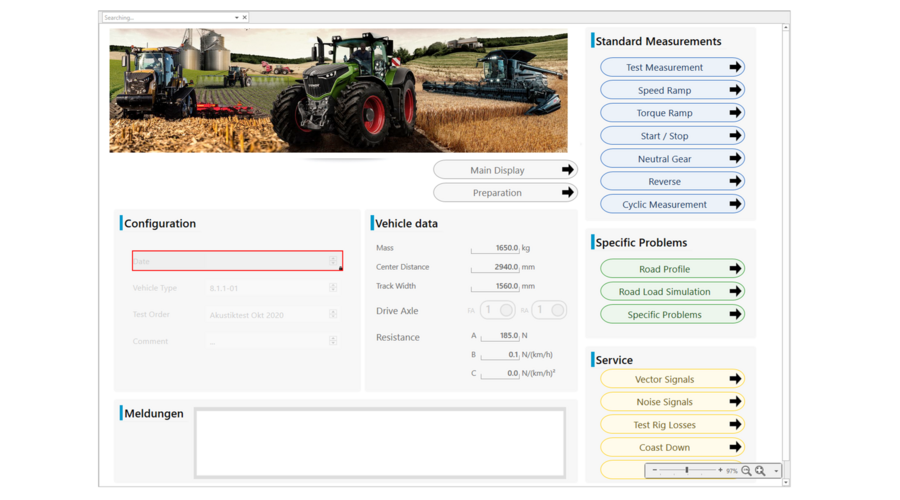

By using the RDDS test stand automation system with all our test stands, the synchronization of several test stations is also feasible. For example, our brake tester dynos can form a common team with function chassis dynos within a test line. Vehicle data only have to be recorded once and measurement results can be documented as a common test result.

Low life cycle costs

When designing our test stands, we naturally also pay attention to possible identical parts. In a team of similar test stands, this also results in advantages in operation and maintenance. The stocking of spare parts is simplified and maintenance can be carried out jointly. And this enables considerable savings in life cycle costs.

Features

- Brake tester dynos for final checks and quality testing in the series production end-of-line (EoL) of heavy agricultural vehicles.

- Customized total solutions for the entire required performance range

- High modularity

- State-of-the-art drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles.

- High reliability and durability

- RENK RDDS test bench automation and data acquisition

Get in contact with our experts from

Team Agriculture: