3rd rail current collector test rigs

- 01Modular current collector support

- 02Very high speed range

- 03Highly dynamic position changes

Our technologies for your demands

The third rail is standard for supplying power to underground and suburban trains. The main focus in designing the third rail is to realize best possible contact of the current collector during total operation. RENK test benches support the sustainable development of needed current collectors and connector rails, because these test rigs make it possible to simulate and analyze their mechanical and electrical properties under real conditions, even at high speeds.

The following tests, for example, are possible with these test rigs:

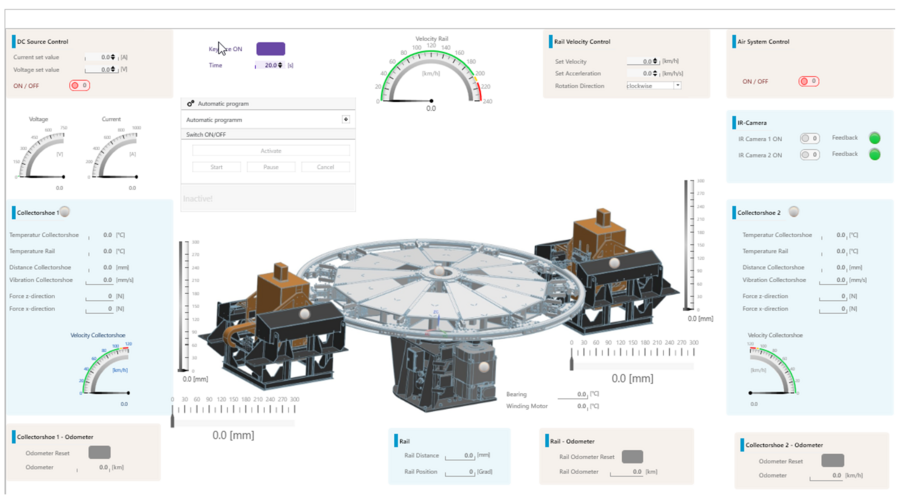

- Contact force measurements

- Uplift measurements

- Arc detection measurements

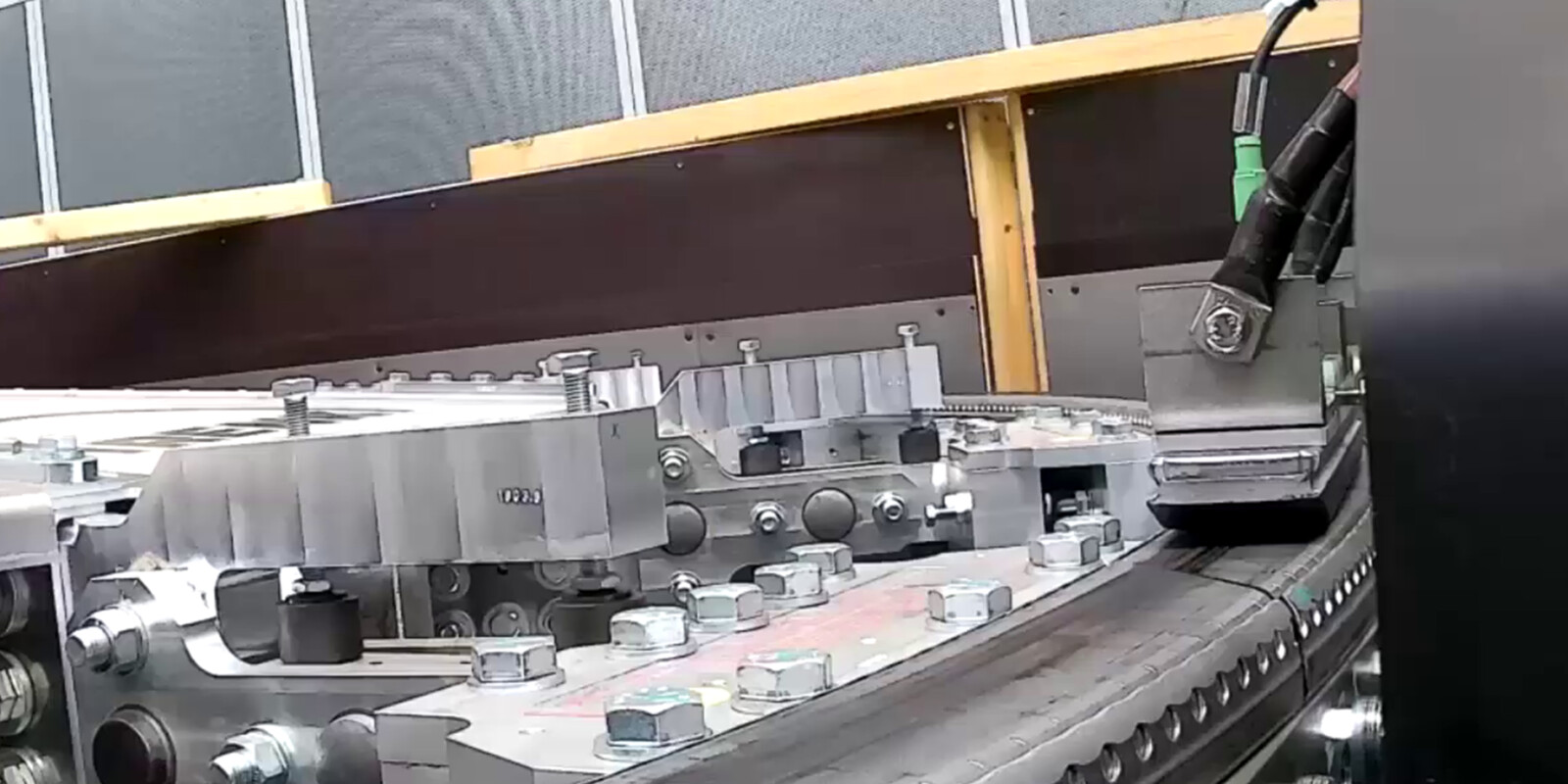

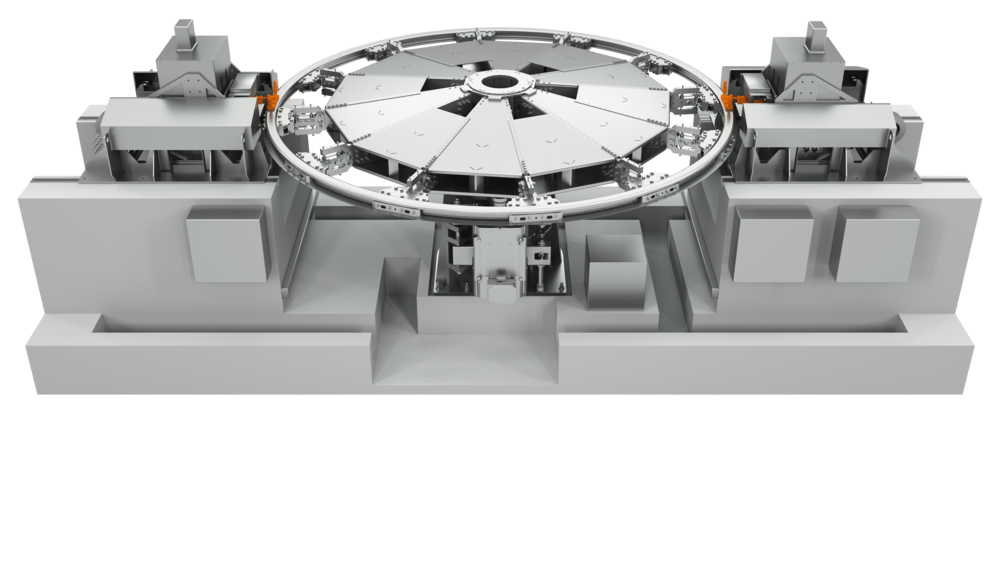

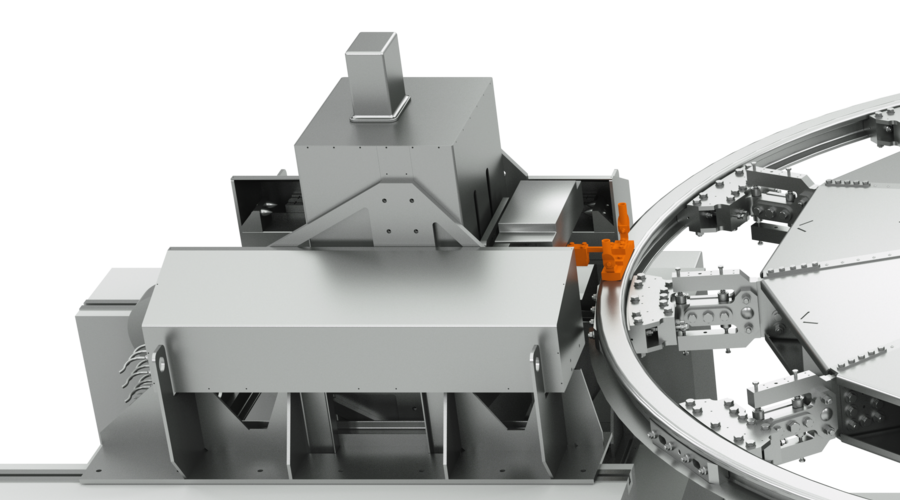

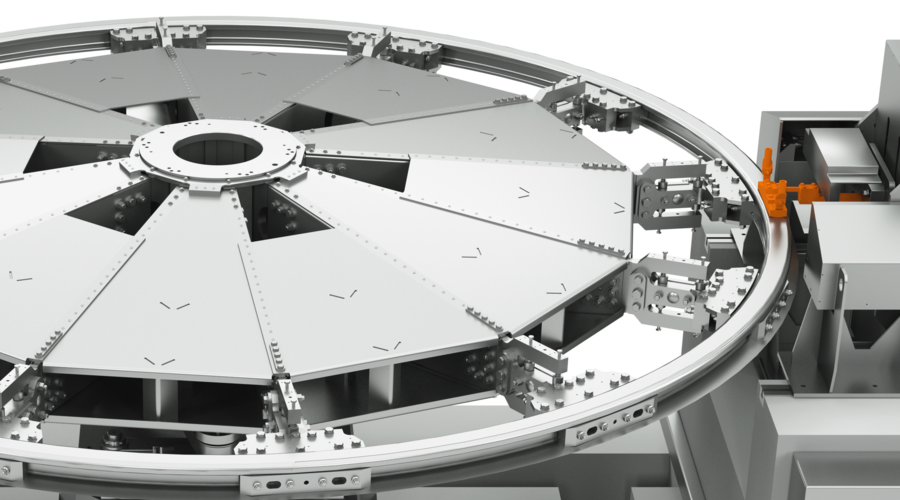

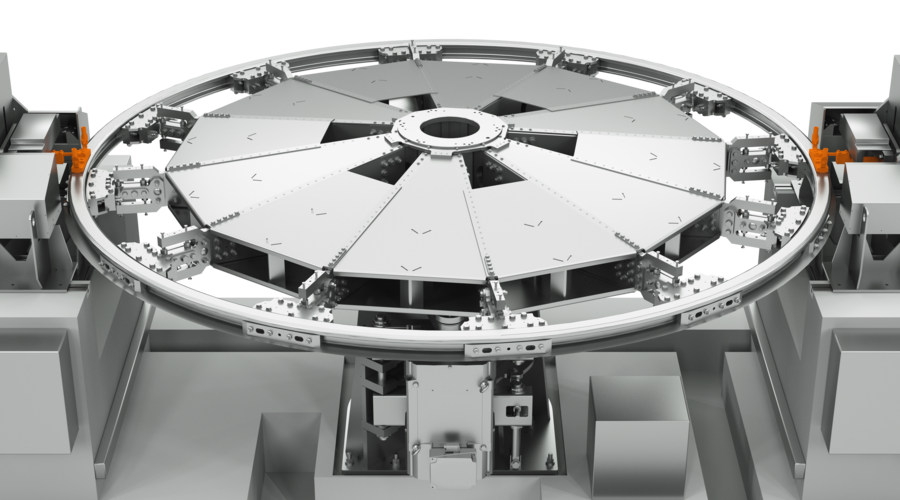

In our test rig concept, the vehicle movement is represented by a rotating rail ring.

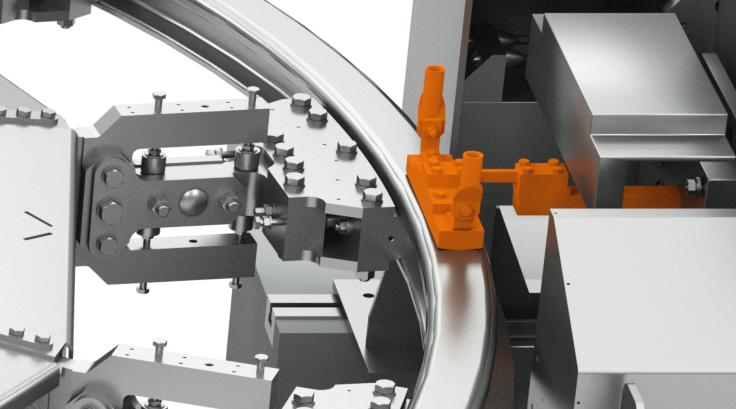

The electric motor-controlled movement of the current collector in two axes allows contact pressure and contact losses of the current collector to be adjusted according to real conditions.

Applicable for top-, bottom- and side-running systems

The specimen fixture of our 3rd rail test stands is designed in such a way that not only different types of current collectors can be mounted, but also different contact directions. Top-running, bottom-running and side-running systems can be tested.

Simulation of very high travel speeds

Due to the size and special bearing of the turntable, very high travel speeds can be simulated. These overspeeds can shorten long-term tests and thus save time and costs.

Highly dynamic position changes

The drive system of the current collector unit ensures high accelerations and movements vertically and horizontally in relation to the rail ring. In this way, the movements of the current collector on the rail up to the loss of contact can be simulated even at high travel speeds.

Curved and rotating rail profile

To represent an endless connector rail, a real connector rail is bent into a ring and mounted on a turntable. Different rings can be obtained from RENK according to customers requirements or manufactured independently by the user of the test bench after training by RENK.

Simultaneous test of two specimens

The certification of current collectors often involves long test runs with several test specimens. Our 3rd rail test stand is designed in such a way that two test specimens can be tested simultaneously. This reduces testing times and costs.

Features

- Test rig for the development and testing of mechanical and electrical components of urban railway´s and underground´s 3rd track

- Curved and rotating rail profile to simulate an endless moving conductor rail

- Movable current collector (vertical and horizontal) for generating dynamic contact changes on the conductor rail

- Partial and long-term tests under realistic current densities

- RENK RDDS test bench automation and data acquisition

Get in contact with our experts from

Team Railway: