Wheelset bearing test rigs

- 01Parallel test chambers

- 02Certified test runs

- 03Environmetal simulation

Our technologies for your demands

Wheelset bearings are exposed to extreme loads at the interface between the wheelset and the bogie frame and must meet a wide range of technical requirements. In order to ensure optimal adaptation to the respective operating conditions, wheelset bearings are developed in close cooperation between manufacturers and operators of rail vehicles.

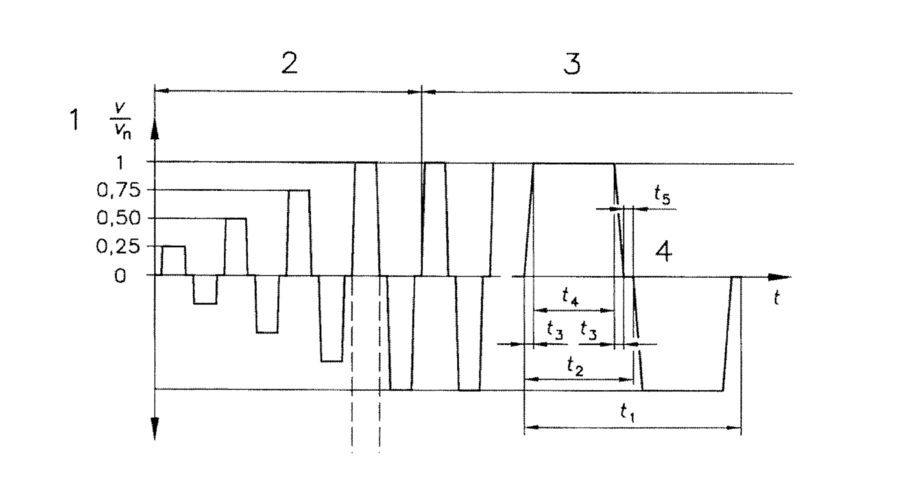

RENK wheel set bearing test benches support this development in a variety of ways, from the individual component to the completely assembled bearing unit. The RENK RDDS automation systems for test benches can be used to simulate complete route profiles in the automatic program and thereby diagnose the effects of all major influencing factors on the wheelset bearings.

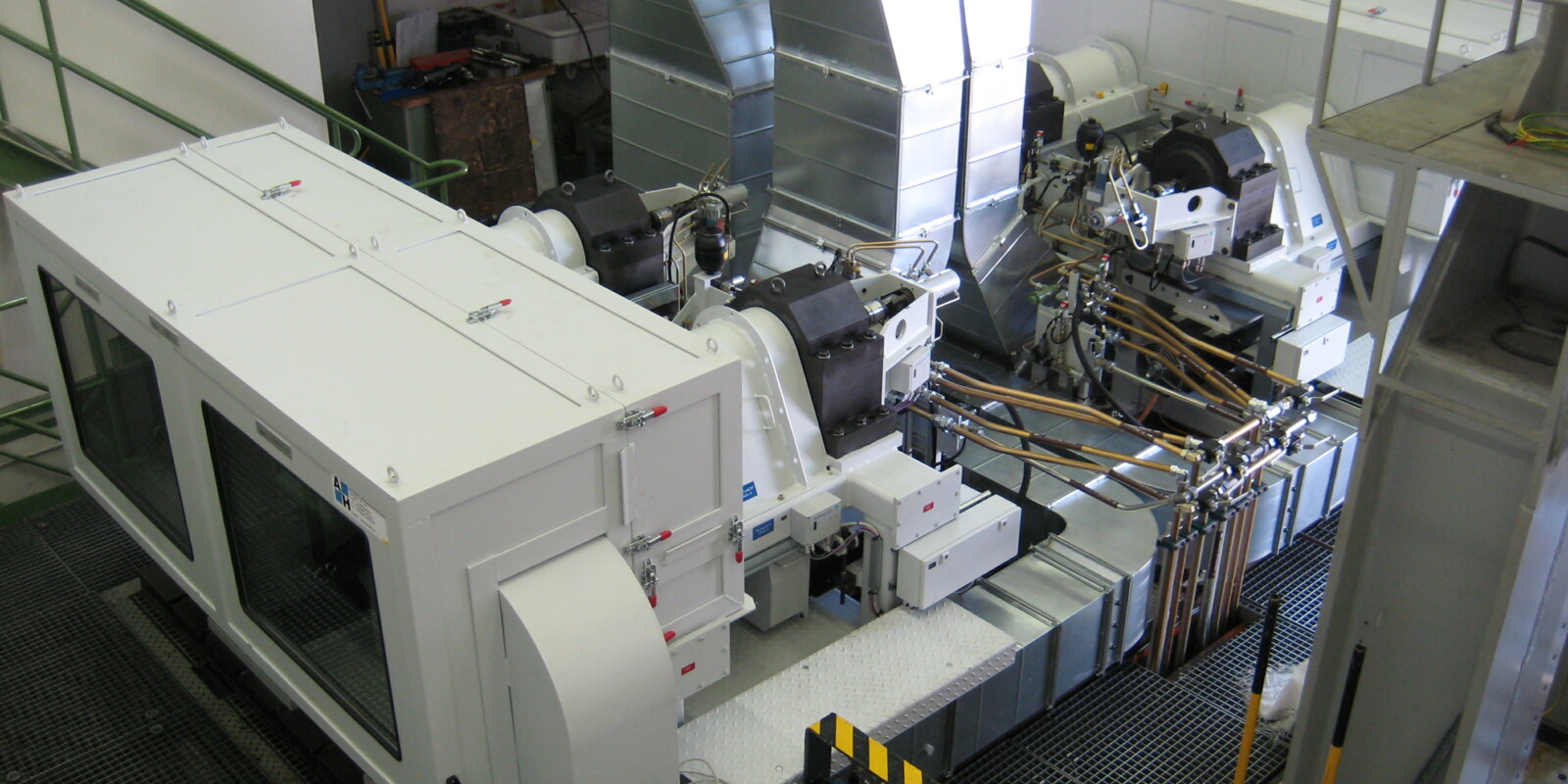

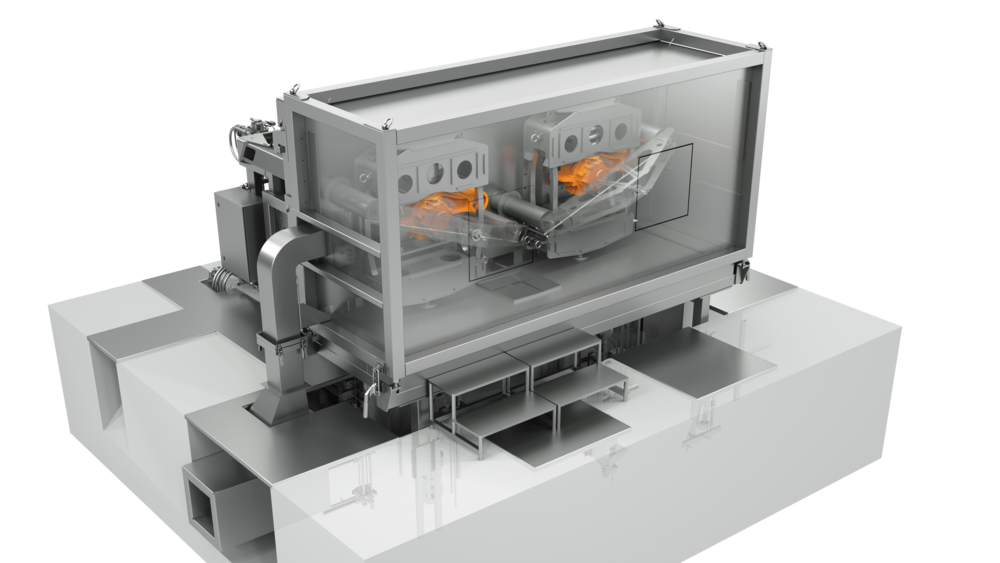

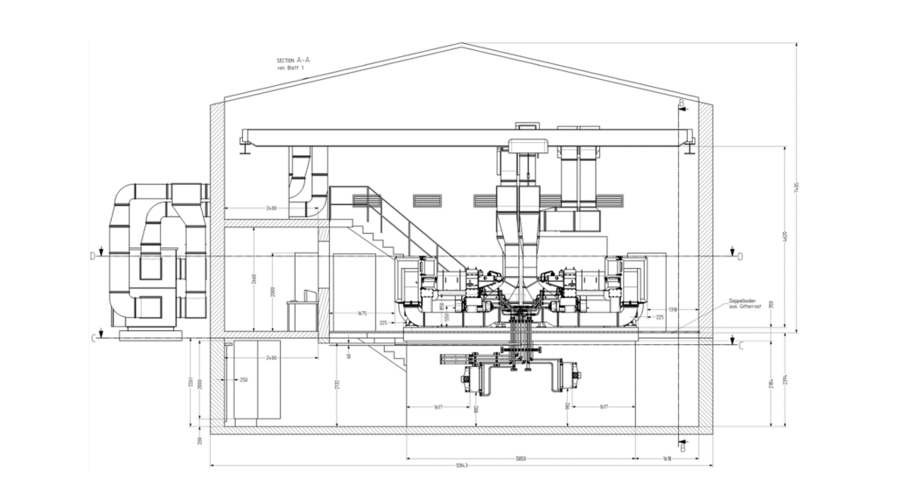

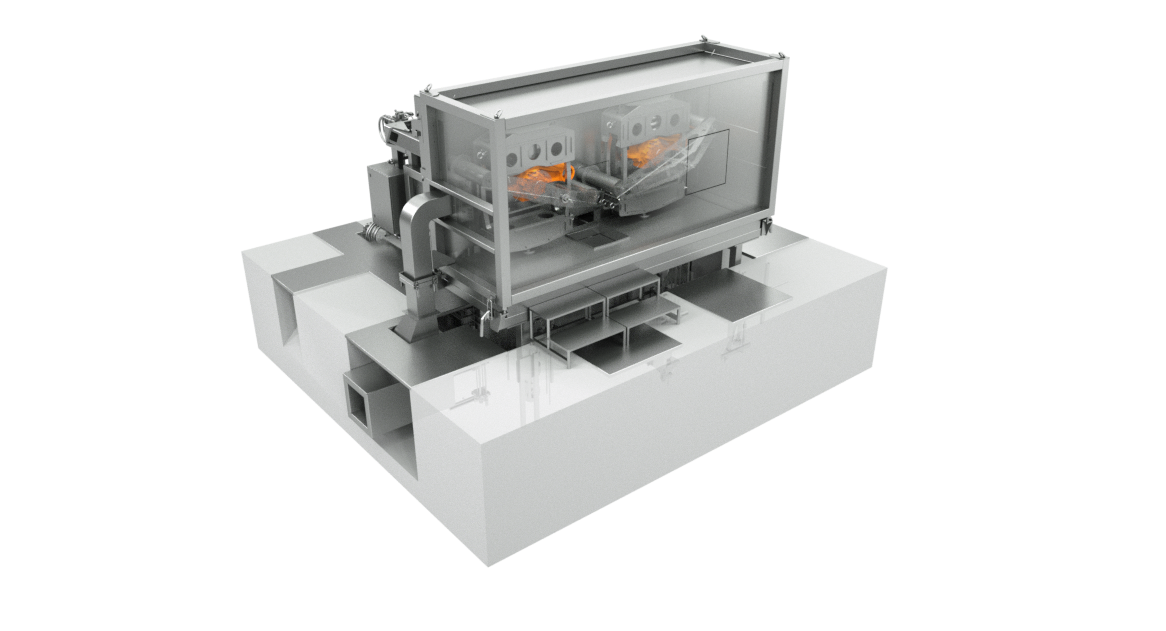

Parallel test chambers for simultaneous testing of several bearings

The certification of wheelset bearings often involves long test runs with several test specimens. Our bearing test stands are designed in such a way that several test specimens can be tested simultaneously in side-by-side test chambers. This reduces testing times and costs.

Certified test runs according to DIN EN 12082 and DIN 51819

Wheel set bearing test benches from RENK can also be used to verify compliance with DIN EN 12082. Special test benches serve the pre-selection and the suitability test of greases and oils according to DIN 51819.

Environmental simulation upon customer requirements

Since airflow cooling has a significant influence on the service life of the bearing greases, RENK wheelset bearing test rigs are usually equipped with an airflow simulation system. However, all other environmental conditions to be considered can also be simulated upon request (rain, low temperatures, snow, ...). Our tasks also include the integration of the total ventilation system to the building.

Features

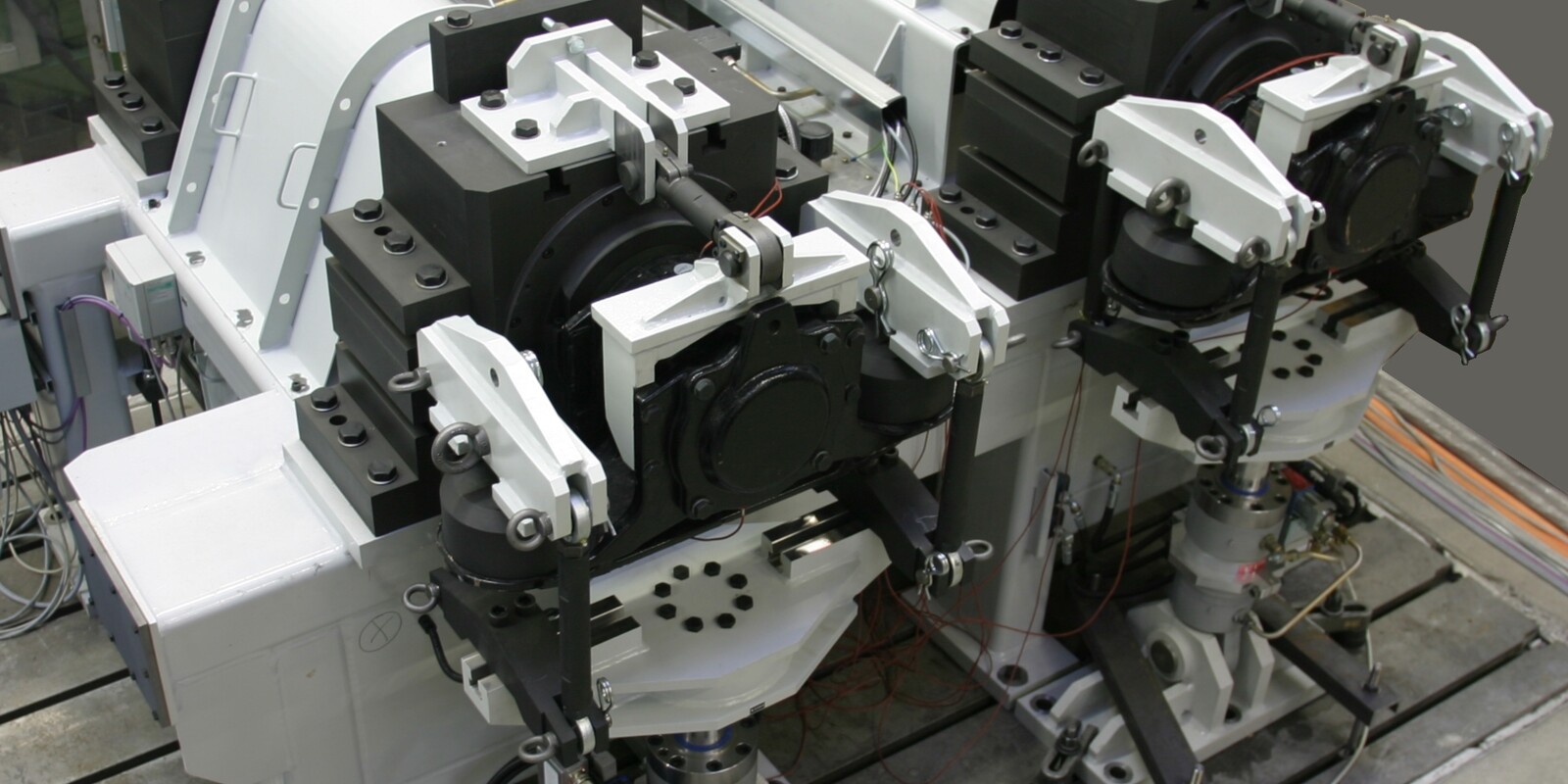

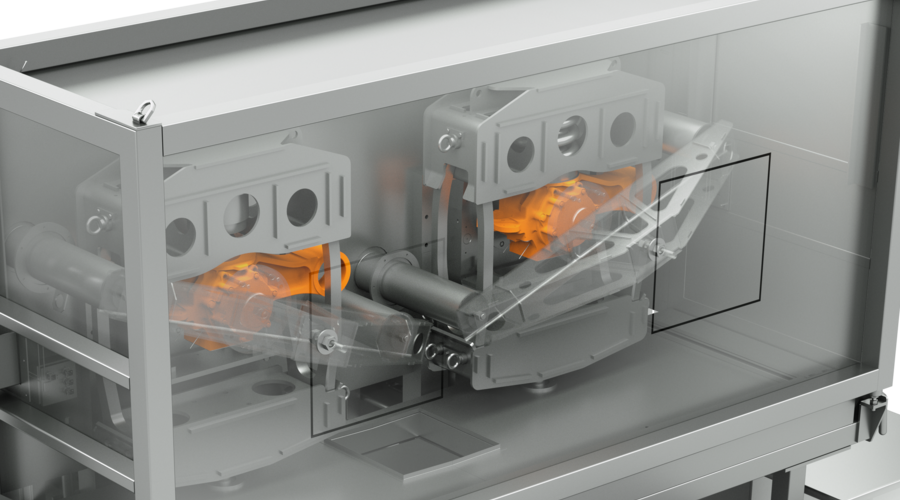

- Testing of wheelset bearings in original housings

- Multiple test chambers for simultaneous testing

- Certified test runs for wheelset bearings and greases and oils

- Hydraulic load unit for controlled application of multi-axis dynamic loads (wheel vertical force + thrust)

- Environmental simulation (rain, low temperatures, snow)

- RENK RDDS test bench automation and data acquisition

Get in contact with our experts from

Team Railway: