Forklift test rigs

- 01High flexibility

- 02Automated test runs

- 03Turnkey testing lines

Our technologies for your demands

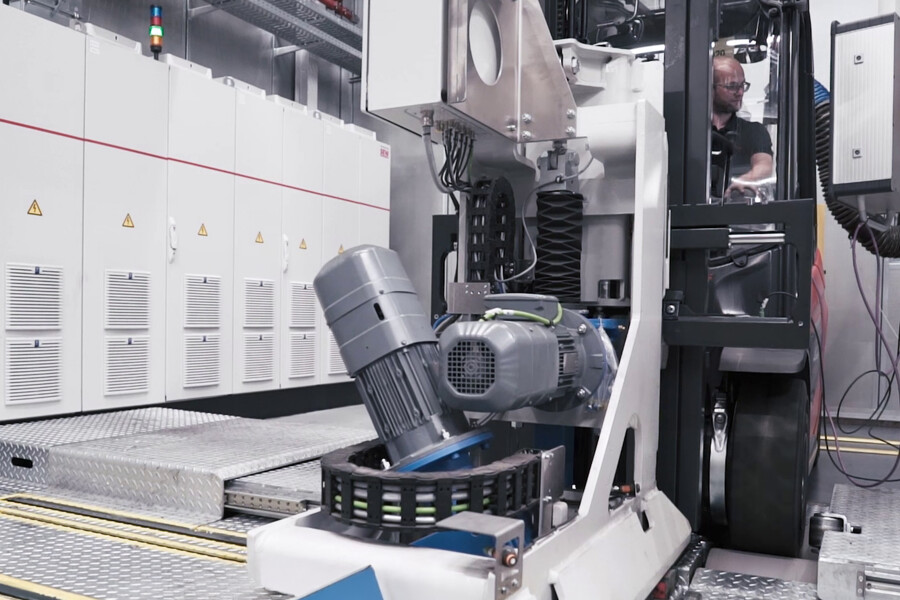

Chassis dynamometers with a single pair of rollers can be used, for example, for the following forklift tests:

- Performance tests

- Functional tests

- Hubload measurements

- Measuring of max. traction force

- Verification of vehicle speed and acceleration

- Measuring of hydrostatic braking force

- Check of parking brake

- Implementation of vehicle specific trials

The forklift testing line can be completed with an additional lift mast test rig:

- Verification of lifting hights and speeds

- Possible tilting angle measurement

- Possible lateral strokes measurement

With test benches from RENK, processing times and costs can be reduced in the development, production and maintenance of forklifts with even higher quality assurance.

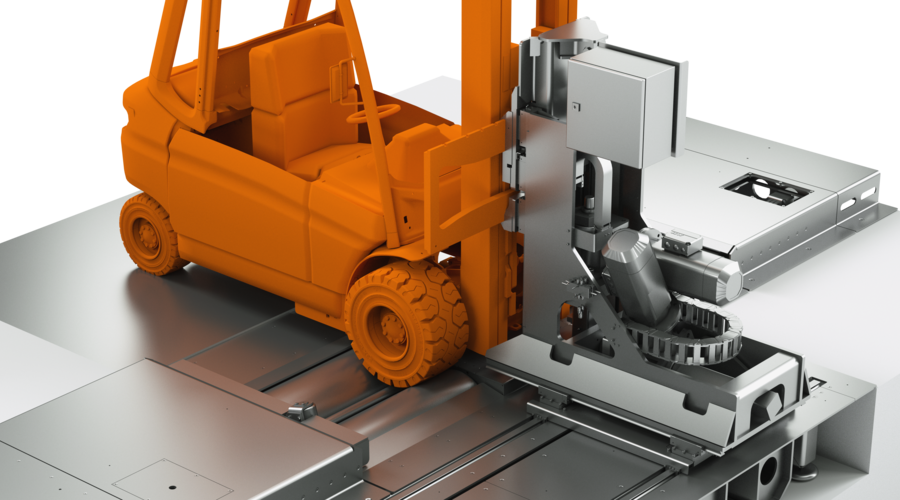

Fast test item changes due to automated setting operations

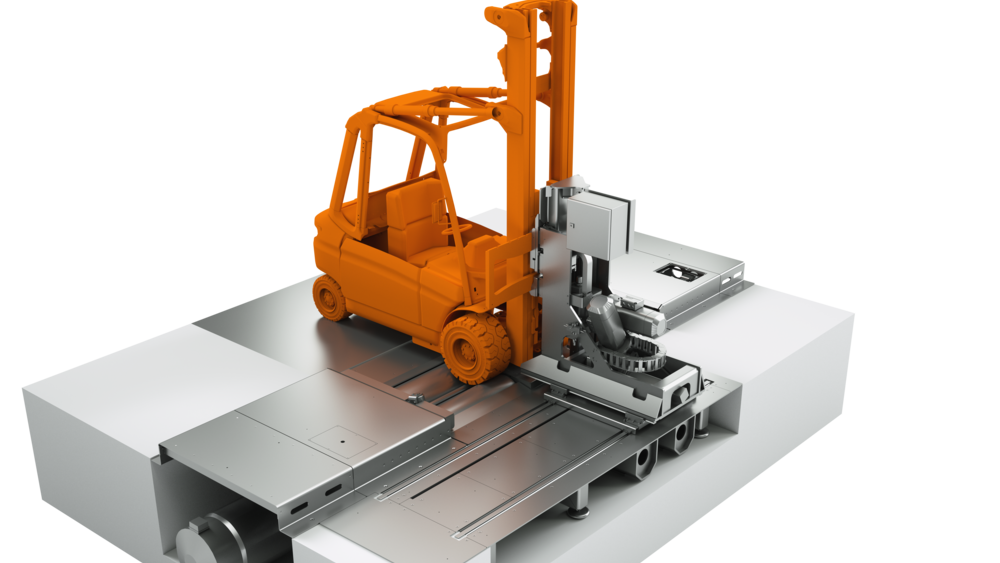

For the testing of special vehicles, the flexibility of the test system Test systems Test systems evaluate the functionality, load capacity and wear of technical components under realistic conditions. is often an important factor. It must be possible to handle changing test specimens without major modifications.

Vehicle dimensions can be stored in the RENK control system so that wheel and tire sizes, lift mast positions and similar are automatically set by the test rig after registration of the current test specimen.

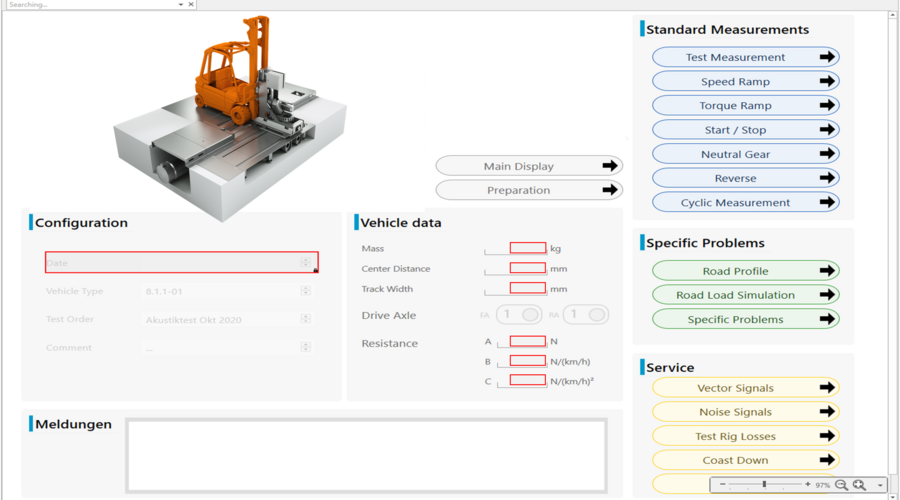

Various customer-specific automatic programs for unattended operation

The RENK test rig automation system RDDS combines control and measurement tasks in one package. Test programs can be stored in the database with the respective vehicle data. This enables short set-up times when changing test items and absolutely reproducible test results. Automatic programs allow unattended 24/7 operation. A real-time interface enables direct communication with the vehicle's CAN bus.

All recorded measured values can be visualized and archived online.

A tailored entire package

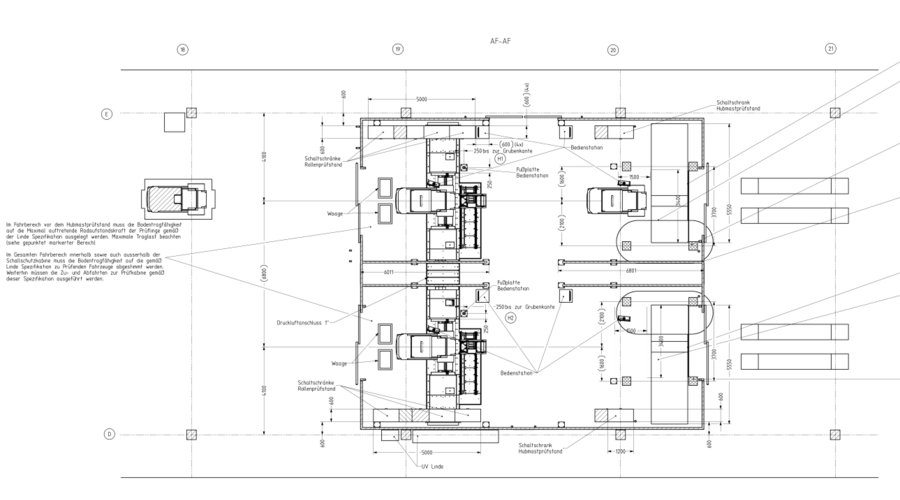

On request, we can also take care of the entire testing equipment, consisting of several testing lines and testing stations.

In addition to the actual test rig, this also includes foundations, test chambers, exhaust and air-conditioning technology, power and media supply, etc.) Furthermore, a large number of measuring devices must be integrated and automated test sequences created.

By using the RDDS test bench automation system, various test stations can be synchronized with each other. The vehicle data only has to be recorded once and the measurement results can be documented as a joint test result.

For us, "true turnkey" means clarifying with the customer all the necessities of his test stand project and working out an optimum scope of services for the customer. From the basement to the roof. From planning to implementation.

Features

- Chassis dynos and lift mast test rigs for the development, production and maintenance of forklifts

- Customized total solutions for the entire required performance range

- High flexibility

- Simulation of all driving loads occurring during operation

- High reliability and durability

- RENK RDDS test bench automation and data acquisition

Take a look at a combined testing line for forklift quality assurance we realized for Linde Material Handling GmbH.

Get in contact with our experts from

Team Special Vehicles: