Developed by Horstman in the 1980s for a range of vehicles, Hydrogas® was designed from the outset to replace torsion bars and provided a revolutionary increase in cross-country mobility.

This allowed the vehicle designer to overcome the internal packaging constraints, vulnerability to mine blast and crew exposure to the fragmentation that all result from torsion bars.

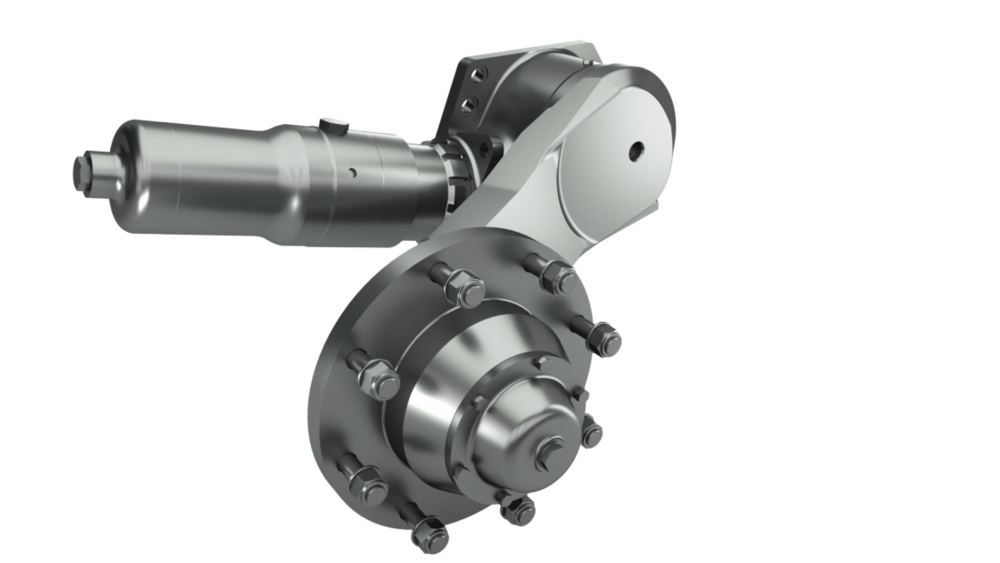

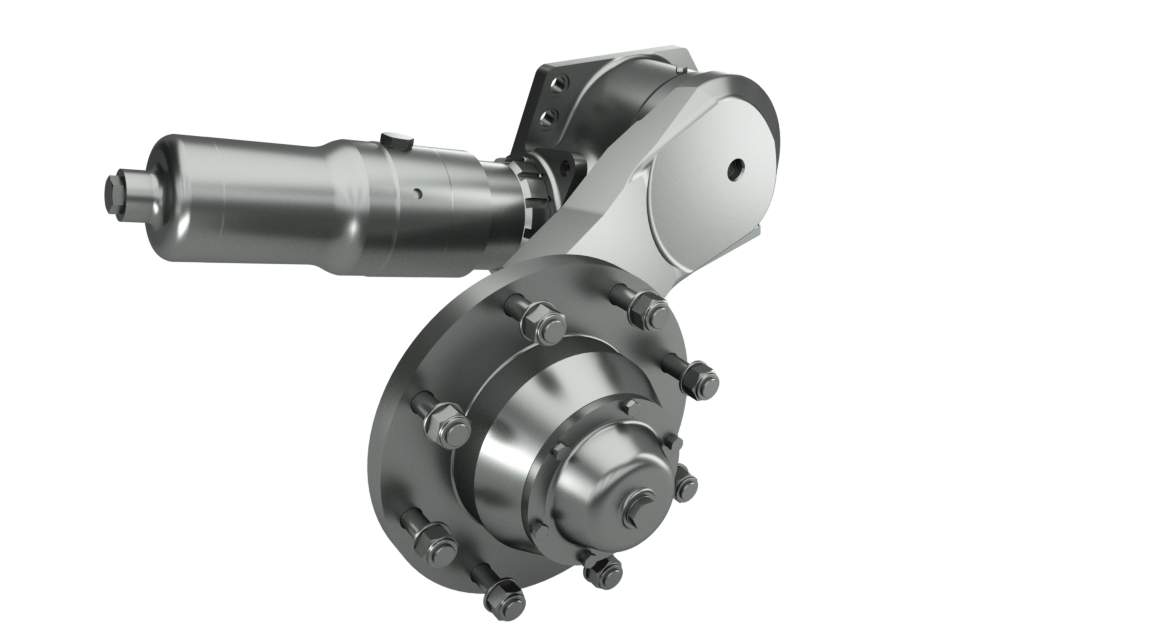

The hydro-pneumatic suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. uses high-pressure nitrogen gas and an integral oil damper. Robust environmental seals make the Hydrogas® a sealed module suitable for robust environments.

Battle proven suspensions with superior ride quality.

By removing traditional torsion bars from the vehicle's interior, this system allows for a more efficient use of space and reduces overall mass, thanks to its integrated system approach. The Hydrogas® system features a Rising Rate Spring and improved damping capabilities, ensuring superior ride quality and handling under a variety of combat conditions. Its independently mounted external suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. not only facilitates a lower vehicle profile, enhancing survivability by making it a less visible target, but also allows for the easy integration of various accessories, further enhancing its operational capabilities. This innovative suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. system, therefore, not only improves vehicle performance through advanced engineering but also contributes to a significant increase in the vehicle's adaptability and effectiveness in the field.

- Additional space for equipment, ability to have a floor mounted emergency escape hatch

- Reduced fragmentation effects from secondary projectiles from mine blast or IED blast

- Hydrogas® get stiffer closer to the ends of travel and so reduces shock loads on the crew and vehicle

- Crew comfort improves, absorbed power reduces and vehicles can drive faster

Damaged units can be replaced more easily than bent or seized torsion bars.

- Ability to lower the turret basket and reduce the height of the vehicle gives improved survivability (lower silhouette)

- The saving of the hull side armour is typically 100-500kg

- Simpler than a torsion bar system which needs separate road arms, bump stops, dampers, torsion bar attachments and protective tubes

- Eliminates the need for multiple torsion bar spring rates as wheels individually adjusted by gas pressure to suit payload or performance

- Charging kit – Hydrobooster™

- Electronic control unit (ECU)

- Wheel hub, light weight wheels, wear guards, bump stops

Hydrogas® from Horstman – empowering multiple vehicles.

Proven in Challenger MBT, CrARRV, AS90, Terrier, K9/K10, Horstman has continuously upgraded Hydrogas® with the latest sealing and friction coatings to improve system life, crew comfort and firing stability.

Application

Downloads

- Horstman HydroGas (4.1 MB)

E-Mail angeben

Bitte geben Sie Ihre E-Mail-Adresse an, um den Download zu starten.

Get in touch with our specialists.