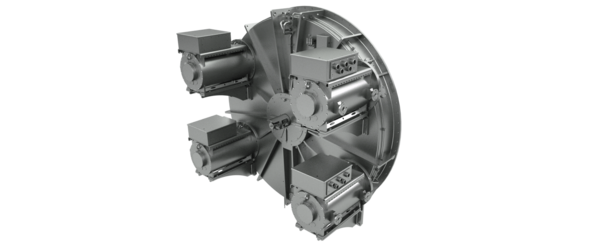

A PTO taps excess power from the main engine to generate electricity for on-board consumers. They eliminate the need for off-engine gensets, which are less efficient and come at the cost of additional fuel consumption. Not all PTOs are equal, however. The challenges inherent to earlier-generation power take-offs limited their usability. The Integrated Front-end Power System (IFPS) from RENK changes everything. Broadly speaking it does the same job as a conventional PTO – but in a completely different way.

Regulations with a deadline

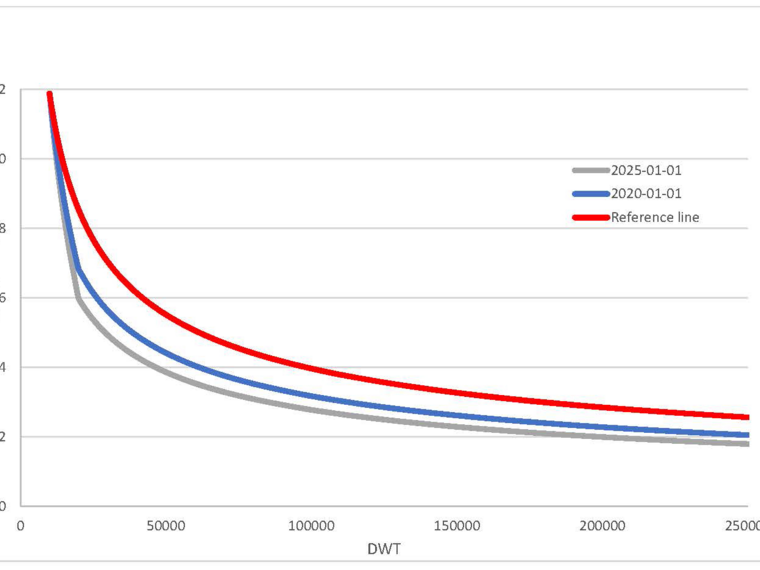

Political pressure is increasing all the time. Freighters constantly have to up their efficiency to keep downing their environmental index. That's what the Energy Efficiency Design Index (EEDI) for new-build vessels is about. And existing ships are covered by the counterpart Energy Efficiency existing ship Index, EEXI. The requirements levels are tightened incrementally, so operators and shipbuilders need new solutions right away. The need for action is urgent, but the market situation lacks clarity. The regulations differ for ships of different types and sizes. On average, freighters will have to slice a whopping 30 percent off their 2013-level figures for fuel consumption.

"Without additional and effective energy-saving devices (ESDs), by 2025 EEDI compliance is not going to be easy", acknowledges Nils Oesterlen, since August this year Head of Marine at mechanical engineering specialist RENK. The bottom line is that many operators have to optimize their propulsion and energy systems as of right now. The only alternative would be to cut back sharply on their current steaming speeds, which would mean "accepting considerable economic losses" states Dominik Elskamp, project engineer at RENK. A PTO goes a long way toward avoiding that outcome. Tapping power from the main engine to supply the on-board electrical systems is a fuel-economizing lead over gensets, cutting CO₂ emissions and saving money.

Without additional and effective energy-saving devices (ESDs), an EEXI / EEDI compliance is not going to be easy. A PTO can be a valid measure tackling the goals.

PTO solutions can achieve a fuel reduction of up to 7 percent.

With a PTO smoothly drawing energy from the main engine to power the on-board electrical consumers, fuel savings in the order of 3 to 7 percent are a welcome prospect. Enter the RENK company, offering an innovative PTO solution called IFPS and fuel reductions as high as 7 percent. That's one whole third of the savings that EEDI and EEXI will require of operators in the very near future. And a totally different ballpark compared to the figures achievable by conventional power take-offs.

Installation and maintenance of PTOs were often a pain, therefore the RENK engineering team took a different approach with the IFPS.

Despite the huge benefits of PTO systems, many ships now afloat still rely on old-school gensets. Invariably, these PTOs had to be situated well aft, clustered close to the propeller shaft. Gear of this design was inherently difficult to install. When the PTO needed repair or maintenance, the entire generator had to be opened and at least partly stripped down. Any ship not in port when this occurred would have to stop at sea, possibly unable to maneuver until the work was completed.

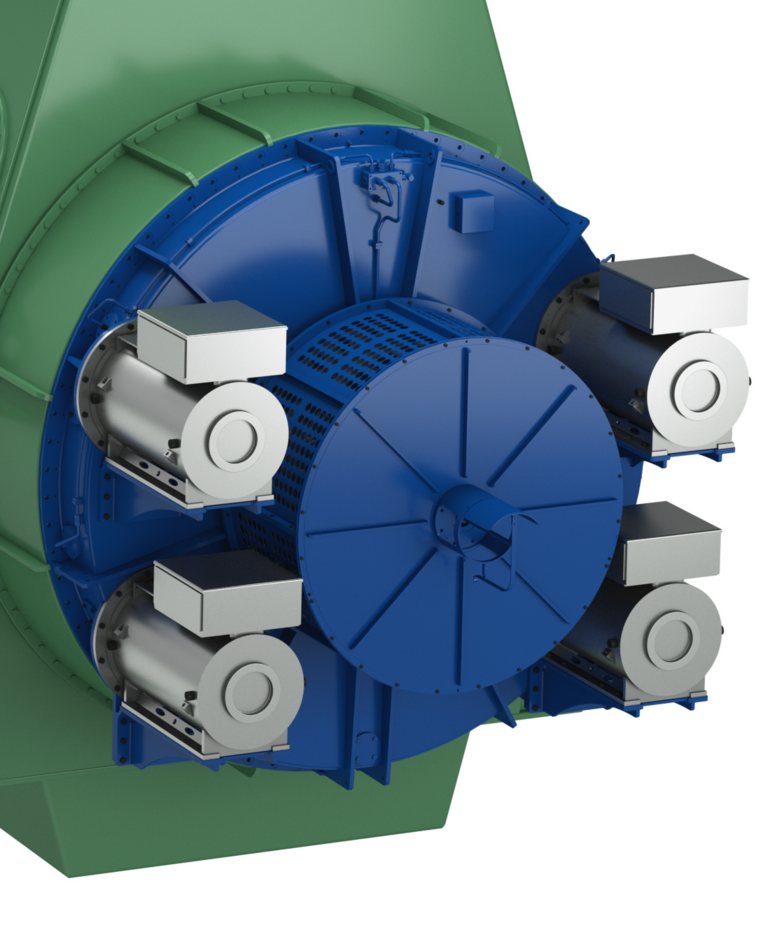

The new IFPS from RENK is the answer. The gear unit, complete with generators, sits right ahead of the fore end of the engine. If it requires attention it can be decoupled easily and without any loss of time. Engine availability is maintained, all the maintenance or repair work can be done while the ship continues on its way. "That just isn't possible when you have a generator mounted at the propeller shaft. With a setup like that you're talking hours of work just to get access", asserts Elskamp.

Not so with the IFPS: "Open the hatch, pull the bolts, keep steaming", is the maritime propulsion specialist's succinct statement of fact. Indeed the IFPS needs very little attention, because the only true wear parts are its rolling bearings. "And replacing them is a very easy job – if needs be even on the high seas." The IFPS sits snug on the front end of the engine, a neat arrangement sidestepping the space problems that bulky PTO systems generally cause in engine rooms. Because of its on-engine position, the IFPS is easier to install than conventional PTOs, it is less susceptible to faults and easier to service. And it frees up space in the engine room.

Rugged and compact design and the upgrade options are highly appreciated by customers.

Big customers from Sweden and France already have the future-proof Integrated Front-end Power System in operation at sea and are very happy with the IFPS. One factor in this success story is the high efficiency of the design. The IFPS from RENK is built around high-speed permanent-magnet generators that push efficiency into the 91 percent bracket. Other systems can manage only about 87 percent. The highly resilient coupling, moreover, isolates the generators from the influence of the engine shaft's movement. So as well as being more efficient, they are more reliable and have a longer service life.

The IFPS has its own dedicated gear unit, so it can tap up to 15 percent of the main engine's power. And the system is custom-configured to the ship's actual power demand. Old-style systems were usable only for a certain type of ship and engine – certainly not scalable for every on-board load demand. The IFPS is modular and up to four space-saving generators can be installed. With 500 or 625 kilowatt ratings per generator, total power can be as high as 2500 kW. So even though the power-generating machinery is much more compact, possible PTO generating power is sufficient even for very large ships.

PTO solutions can also provide "cleaner electricity".

The speed of the main engine can distort electrical output, an added drawback with any conventional PTO arrangement. When shaft speed goes down because the ship is steaming slower, each PTO system's output has to be modulated accordingly. This modulation produces electrical noise. The IFPS has insulated gate bipolar transistor (IGBT) rectifiers to counter this effect and keep total harmonic distortion low. They minimize noise and produce a constant sinusoidal waveform. By this the supply to on-board electrical consumers remains constant, regardless of main engine speed. "This means the IFPS generates a high-quality electricity supply. That ensures the functionality and durability of very sensitive instruments such as radar and other navigation devices", explains Elskamp.

The rectifiers also permit operation in various modes. For example, the innovative PTO system can be operated in parallel with gensets or supply the on-board system with electricity entirely on its own when the vessel is at sea. By opting for the IFPS, customers have a solution that is not only reliable and technically innovative, but also very flexible.

Approved by MAN and WinGD and demonstrating impressive savings

The IFPS is compatible with all popular families of low-speed two-stroke marine propulsion engines from MAN and WinGD. Both manufacturers have approved the IFPS as an add-on for their engines and are particularly impressed by the ease of installation and the robust, efficient design. From the customer point of view, the reasons for choosing an IFPS can also be expressed in figures. Compared to auxiliary gensets burning extra fuel for on-board electricity, an IFPS rated at 1000 kW claws back about USD 235,000 a year on running costs. A 1500 kW IFPS could up that figure to USD 335,000. An IFPS has paid for itself within 2.5 to 3 years and at current fuel costs it would save a medium to high seven-digit sum over a ship's expected service life of 15 to 20 years.

Due to the various advantages and positive impact the IFPS is sailing the seas.

Retrofitting the space-saving and powerful IFPS from Augsburg, Germany, is a sustainable and worthwhile investment for vessels already sailing the seas. "The engine manufacturers actively suggested that we should develop a system of this nature", recalls Oesterlen. He, Elskamp and the RENK team behind the IFPS are convinced that the technology is the way to go for the future. Other PTOs are not nearly as advanced and scarcely comparable in terms of return on investment. The team is proud of the fact that on top of the WinGD and MAN recommendations as an accessory for their two-stroke engines, the IFPS is operating successfully in several vessels now sailing the world's oceans. Day in, day out, it is helping to reduce operating costs and cut CO₂ emissions. "Those freighters have been delivered, they've completed their sea trials and now they are in commercial operation", says Elskamp.

Take a look at related stories and products to shaft generators.

In case you have any question in regard to Condition Monitoring get in touch with our experts from the marine business.