Whirltowers

- 01Single and bi-directional operation

- 02Minimized structural vibrations

- 03Unique control and testing capabilities

Our technologies for your demands

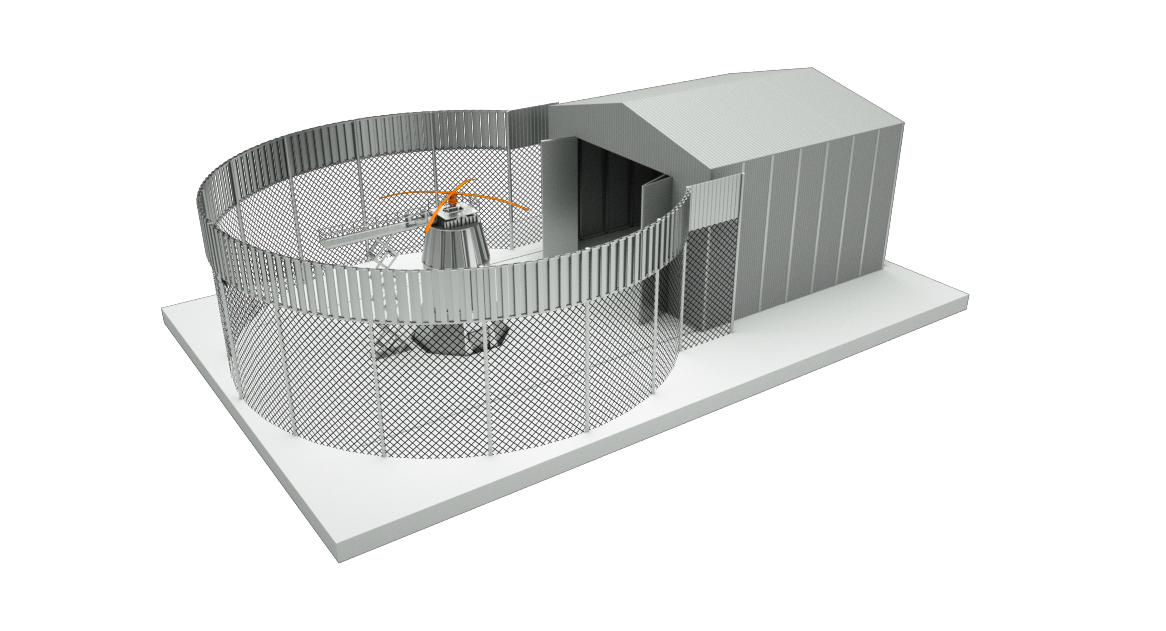

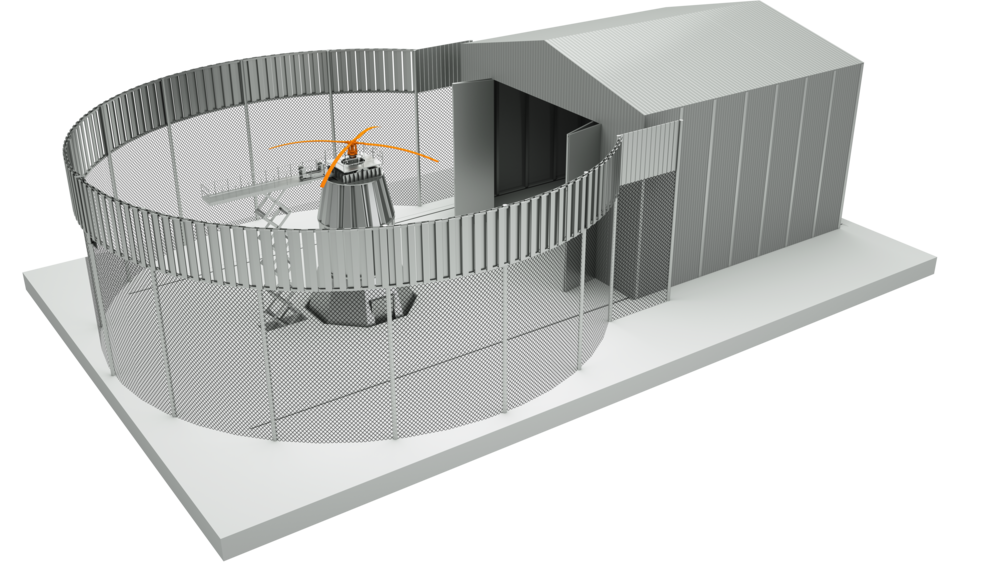

The exact design of test rigs for helicopter main gear units (MGB) requires considerable know-how about the interface to the rotor blade system and all the loads occurring there during operation. As the market leader for MGB test rigs, RENK has a very high level of expertise in this field. It is therefore not surprising that we are also the right partner for the design and assembly of whirltowers for rotor blade testing.

Our Whirltowers can be used for the following tasks in development and production:

- Blade balancing

- Blade development

- Main rotor hub system development

- Static and dynamic performance measurements

RENK test benches are exactly tailored to individual customer requirements and can, on request, include not only the drive system with rotor head mounting, but also other required elements such as measuring equipment, power supply or special building components.

Clockwise or counterclockwise

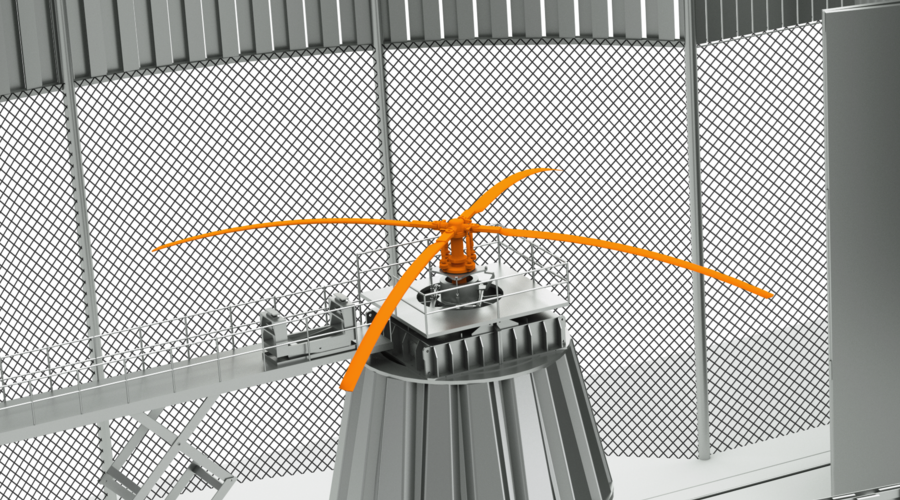

When designing our whirltowers, we can take into account a wide range of rotor configurations. The most common are clockwise or counterclockwise turning single rotors. But also the drive and testing of coaxial counter-rotating rotors is possible.

Minimized vibrations and best efficiency

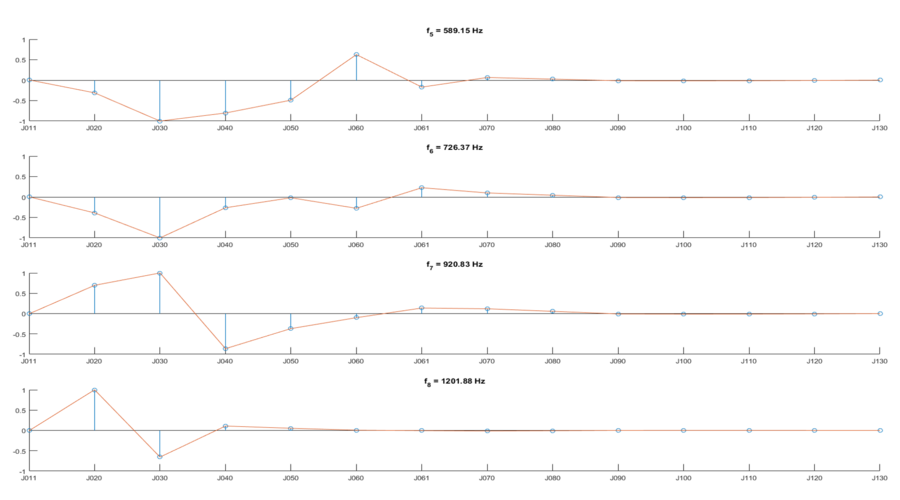

RENK is known worldwide for using state-of-the-art calculation, simulation and manufacturing methods to minimize vibrations in powertrains and increase their efficiency. And this expertise is also particularly essential in test rig construction.

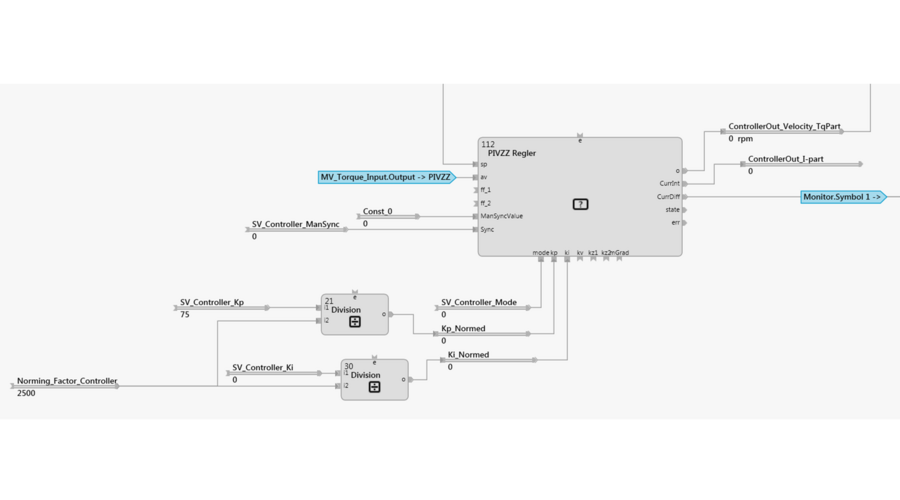

RDDS automation system

Our RDDS test stand automation system combines control and measurement tasks in one package. Test programs can be easily prepared and then executed using graphical operator guidance. A real-time interface allows communication with the blade pitch control system to simulate specified flight maneuvers interactively and realistically. All recorded measured values can be visualized and archived online.

Features

- Test rigs for development and testing of a wide variety of rotor concepts

- Torsion-resistant and low-vibration design

- Unrivaled reliability and durability

- Master RENK RDDS automation system and measurement acquisition

- Optional: Interactive real-time interface to blade pitch control