Performance chassis dynos (R&D)

- 01“True Turnkey” service

- 02Modular and expandable

- 03Unique compact design

Our technologies for your demands

Single-roller chassis dynamometers bring the open terrain into the laboratory. Large rollers, highly dynamic drive units and state-of-the-art control technology enable very realistic and reproducible road travel simulation for passenger cars and heavy vehicles. A wide variety of driving profiles can be examined in vehicle development (R&D) even before the first road trip, or real field measurements can be reproduced on the test rig.

The tests to be carried out in the development process are vehicle and customer specific and may include, for example, the following topics:

- Performance and functional measurements

- Endurance measurements

- Simulation of uphill driving under full load or braking operation during downhill driving

- Simulation of different payloads

- Simulation of changes in driving direction

- Single wheel measurements

- Investigations into the vertical dynamics of vehicles and the longitudinal compliance of wheel suspensions Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain.

- Simulation of different road surfaces

- Fuel or electric power consumption measurements

- Dynamic investigations of driver assistance systems

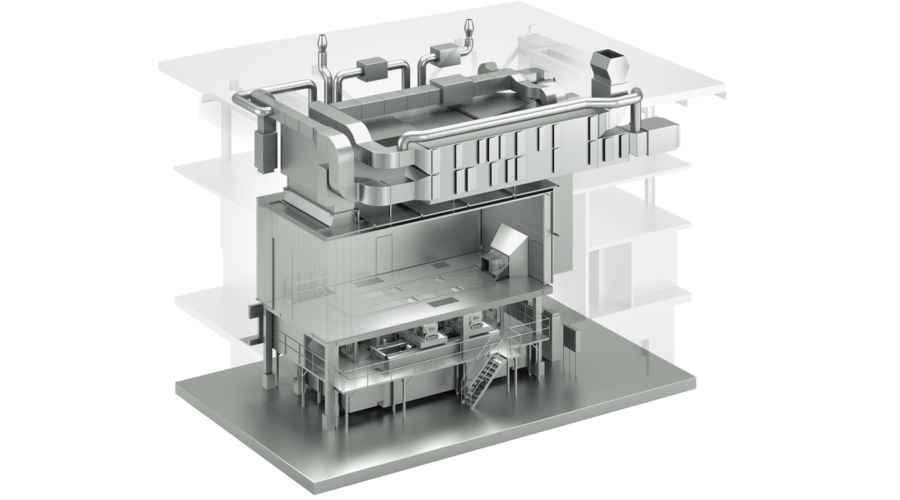

RENK chassis dynos can also be installed in the following test chambers if prepared accordingly:

- Climatic chambers

- EMC measuring chambers

- NVH test chambers

- Wind tunnels

- Altitude chambers

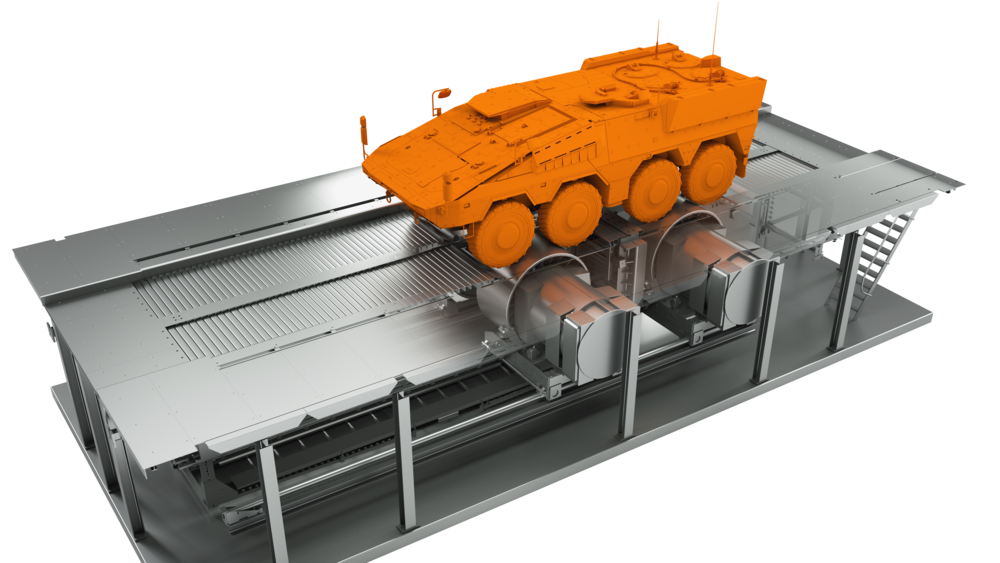

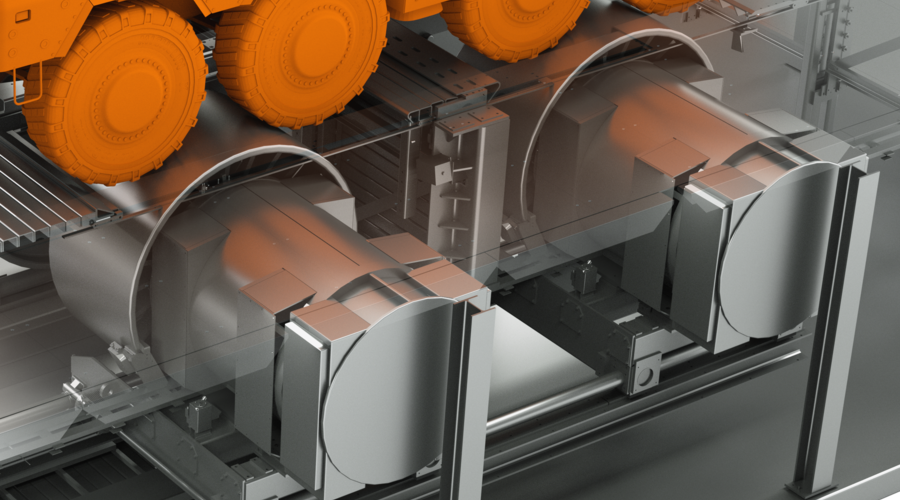

The rollers can be single-driven, in pairs or per axle, depending on the application. The number of rollers is predetermined by the vehicles to be tested. The distance between the rollers is adjustable to the wheelbase of each individual vehicle.

Special roadshells attached to the rollers can be used to simulate different road surfaces. Different bump bars on the roller surface can simulate obstacles or uneven road surfaces.

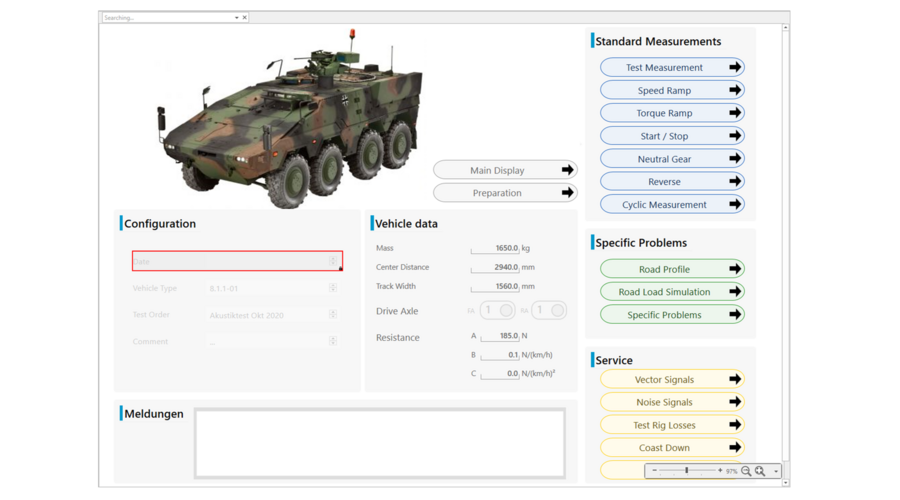

The RENK RDDS test stand automation system can manage all common test programs as well as self-assembled test runs.

“True Turnkey” service exactly according to customer needs

Depending on their intended use, complete vehicle test stands also require extensive infrastructure on the building side (foundations, test chambers, exhaust and air-conditioning technology, power and media supply, etc.). In addition, a wide range of measurement equipment has to be integrated and automated test runs created. For us, "true turnkey" means clarifying with the customer all the necessities of his test stand project and processing an optimum scope of services for the customer. From the basement to the roof. From planning to implementation.

Modular and expandable test system for a wide range of testing tasks

The change of test requirements goes in line with the further development of the vehicles. For this reason, complete vehicle test stands, which are usually operated for decades, must have a very high flexibility. The adaptation of new specimens or the modification of test programs can be carried out by the operators of our test benches themselves. For more extensive adaptations, our experienced service team is at your disposal.

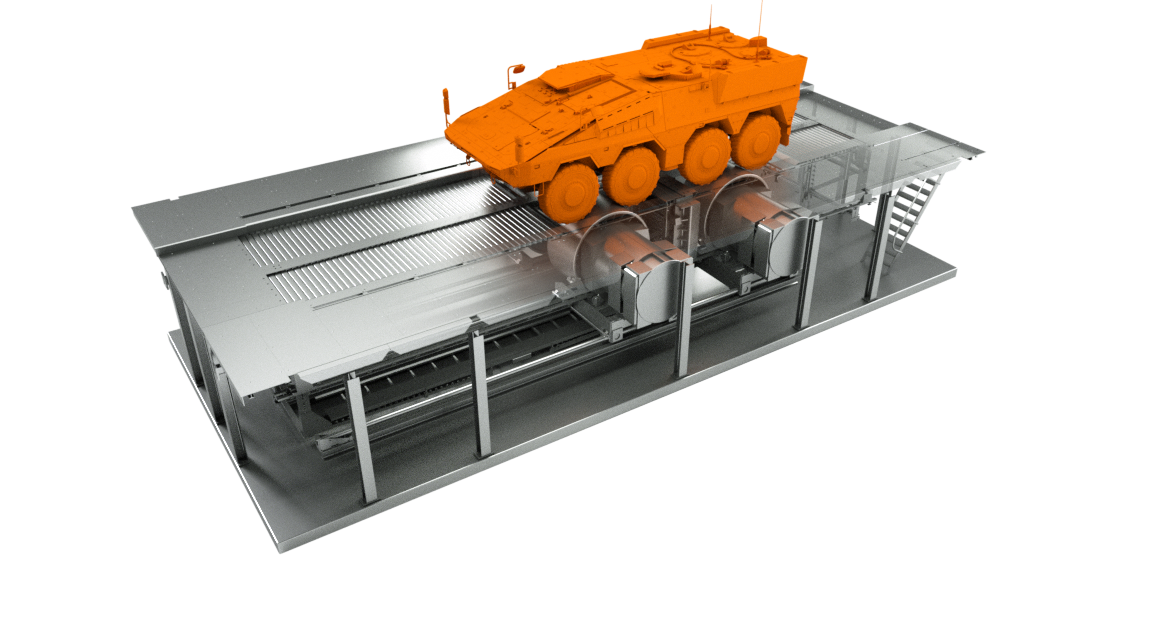

Unique compact design

Through constant exchange of experience with our customers and continuous further development of our drive solutions, we can offer uniquely compact vehicle test benches today. Our test stands require the minimal amount of ground work in their performance range. For this reason, RENK test stands are also perfectly suited for retrofitting in existing buildings. And in new buildings, too, less ground work naturally means lower costs.

Features

- Performance Chassis Dyno for the development of heavy armored wheeled vehicles.

- Customized total solutions for the entire required performance range

- High modularity

- State-of-the-art drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles.

- High reliability and durability

- RENK RDDS test bench automation and data acquisition