CP4WT

Coated Pins for Wind Turbines

The expansion of wind turbines plays a key role in achieving national and international climate targets. In order to realise these goals, wind turbines must deliver increasingly higher outputs at lower costs. This requires gearboxes with a higher torque density and lower costs. In order to fulfil these requirements, plain bearings are used in the planetary stages of the gearboxes. Conventional plain bearing concepts, consisting of a steel bolt onto which a bronze sleeve is joined, present economic difficulties in terms of production and material costs. To remedy this, a thin bronze coating is applied directly to the pin in modern bearings. Common manufacturing processes for this are laser material deposition (LMD) or extreme high-speed laser material deposition (EHLA).

Plain bearings are often tested on radial load test rigs, but these cannot apply real load collectives. The additional torques that occur in the gearboxes of wind turbines due to the helical planetary gears cannot be adequately modelled. This results in abstraction losses that make it difficult to transfer the test bench results to the real application. In order to take these real loads into account, subsystem test benches must be used, which is associated with high expenditure and operating costs. Cost-effective testing and precise evaluation under real load conditions is therefore not possible. In order to qualify the plain bearing concepts with coated pins, a new type of test rig is therefore required that enables the bearings to be tested under real load conditions.

Research objectives

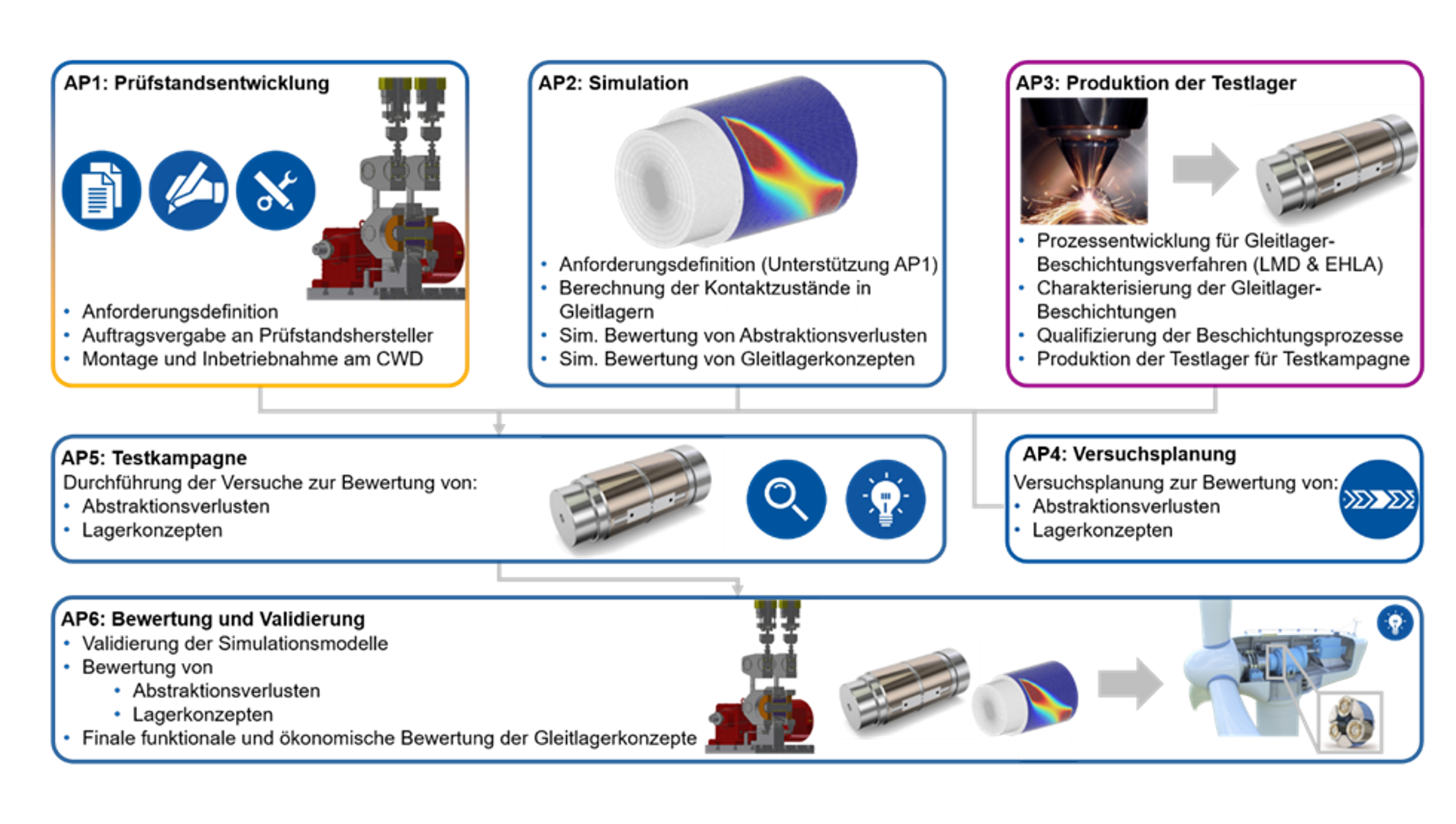

The main objective of CP4WT is the functional and economic qualification of coated planetary pins in wind turbines with regard to production methods and process parameters. In order to test the bearing concepts cost-effectively under real load conditions, a new type of test rig is being developed and built.

The sub-goals of the project are

- Identification of critical load conditions in planetary gear bearings of wind turbines

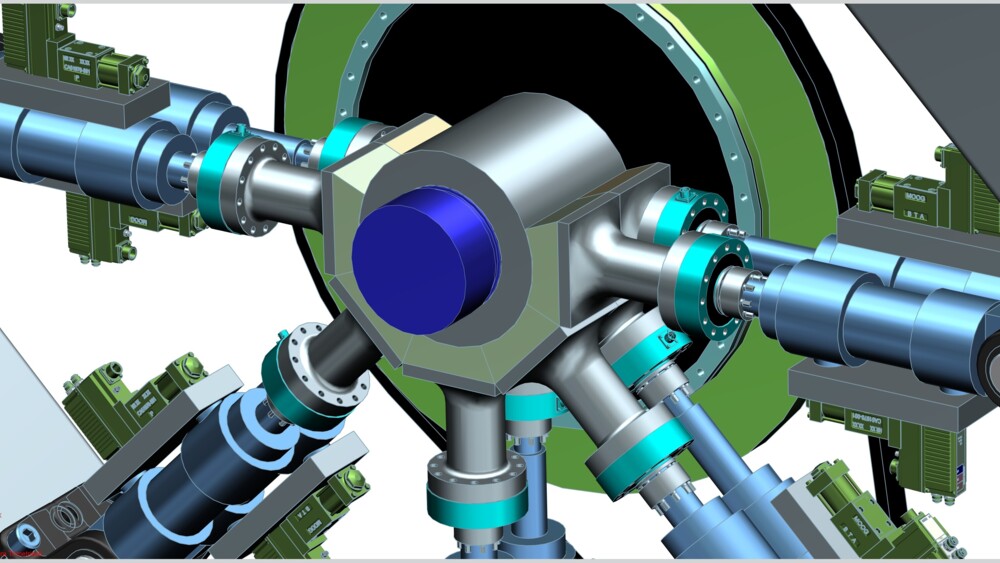

- Development and validation of a suitable test rig using CAD, FEM and EHD software.

- Simulative evaluation of abstraction losses and plain bearing concepts

- Characterisation of plain bearing coatings and qualification of the coating processes

- Planning and implementation of a test campaign to qualify the bearing concepts and abstraction losses

Duration

01.04.2025 -- 31.03.2028

Fabian Renger

Product Manager for Energy Generation Test Rigs

Phone number: +49 821 5700 1311

Email: [email protected]

Project coordinator:

RWTH Aachen (Chair for Wind Power Drives, CWD)

Project partners:

IXUN Lasertechnik GmbH

Associated project partners:

RENK GmbH

Schaeffler

Kugler Bimetal

SKF

Ingenieurgesellschaft für Strukturanalyse und Tribologie mbH

Flender

ACunity GmbH