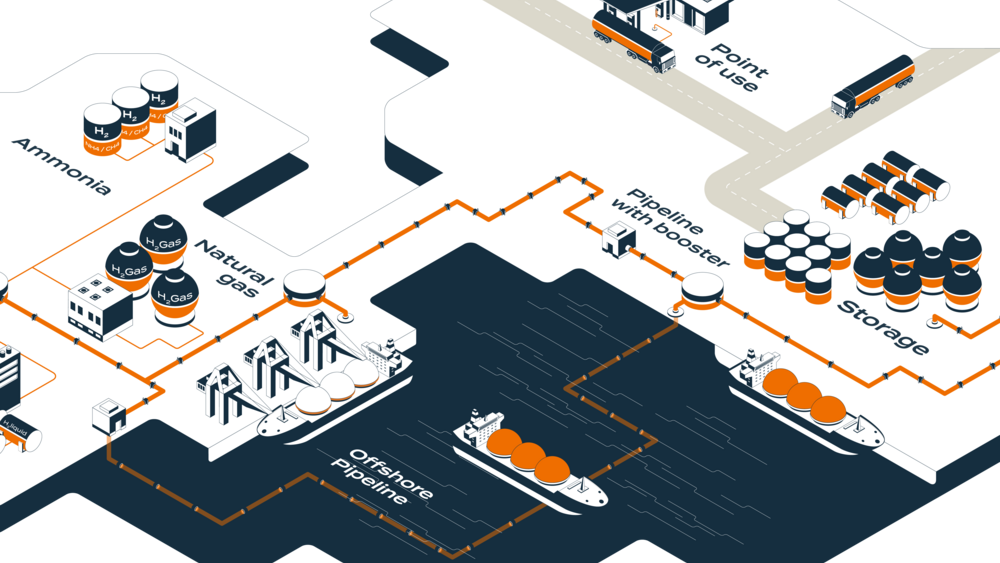

Following the production of Hydrogen, the next step in the value chain is local storage or the transportation via pipelines to the next storage location or the point of demand. Drivetrain solutions are in place throughout the hydrogen infrastructure with large booster or compression stations expected every 100-300 km and storage locations. Naturally also the transportation via LNG carrier is another commonly approach to globally ship hydrogen in the world.

Generating power environmentally friendly and sustainably

Renewable energy can be produced through various methods, each harnessing natural resources that are replenished naturally. With our various products we help making power generation environmentally friendly, reducing greenhouse gas emissions, and contributing to sustainable energy systems:

- Wind Turbines: Producing high-performance gear units and couplings Couplings Couplings are used to connect two shafts for the transmission of torque, and to compensate for misalignment or movement. for efficient wind energy conversion.

- Hydropower: Supplying gear units and transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. components for hydropower plants.

- Solar Power: Providing gear units and bearings for solar tracking systems to enhance panel efficiency.

- Marine Renewable Energy: Offering gear units for marine applications, aiding tidal and wave energy converters.

These products improve the efficiency and reliability of renewable energy systems.

From gaseous to liquid for long-distance transportation

Hydrogen liquid transformation typically occurs during the storage and transportation stages of the hydrogen supply chain. Liquid hydrogen is commonly used for long-distance transportation, such as shipping or trucking, as it has high energy density and occupies less volume than gaseous hydrogen.

Liquid hydrogen needs to be stored and handled at extremely low temperatures. The drivetrain components must be designed to withstand these cryogenic temperatures without compromising performance or reliability. The choice of materials, lubrication systems and thermal insulation is crucial. Handling and storing liquid hydrogen present inherent safety risks due to its low boiling point, flammability, and potential for rapid vaporization. Drivetrains must incorporate robust safety features, such as leak detection systems, pressure relief devices, and emergency shutdown mechanisms, to mitigate the risk of accidents.

A hydrogen carrier for energy storage and transportation

Hydrogen ammonia transformation is a crucial step in the production of ammonia, which is used primarily as a fertilizer in agriculture and also in various industrial processes such as pharmaceuticals, plastics, and explosives. In the context of the hydrogen sector, ammonia can be used as a hydrogen carrier for energy storage and transportation. The synthesis of hydrogen into ammonia is easier and safer to store and transport than pure hydrogen gas.

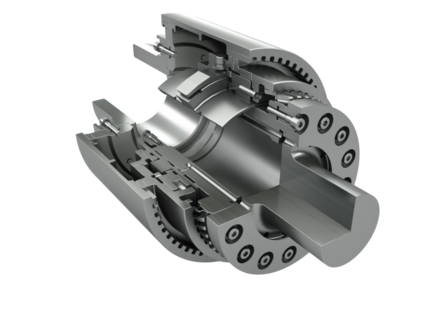

The challenges for drivetrains are the high pressure and temperature during the ammonia synthesis and the high torque and power requirements of the reactors and associated components. Hydrogen gas can lead to the embrittlement of metals, resulting in a degradation of mechanical properties and possible failure of drivetrain components. Careful material selection and design considerations are necessary to minimize the risk.

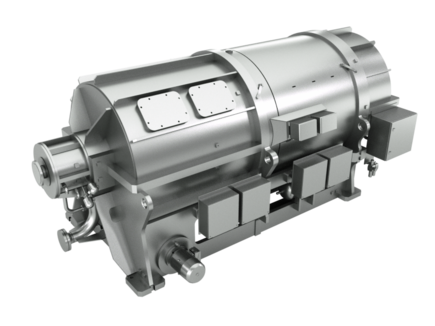

Keeping the pressure up for a seamless flow

Booster systems are required for hydrogen pipelines primarily to maintain the pressure demanded for the efficient and reliable transportation of hydrogen over long distances. They also provide flexibility and scalability for hydrogen pipeline networks, allowing them to adapt to changes in demand, changes in terrain and the addition of new pipeline segments.

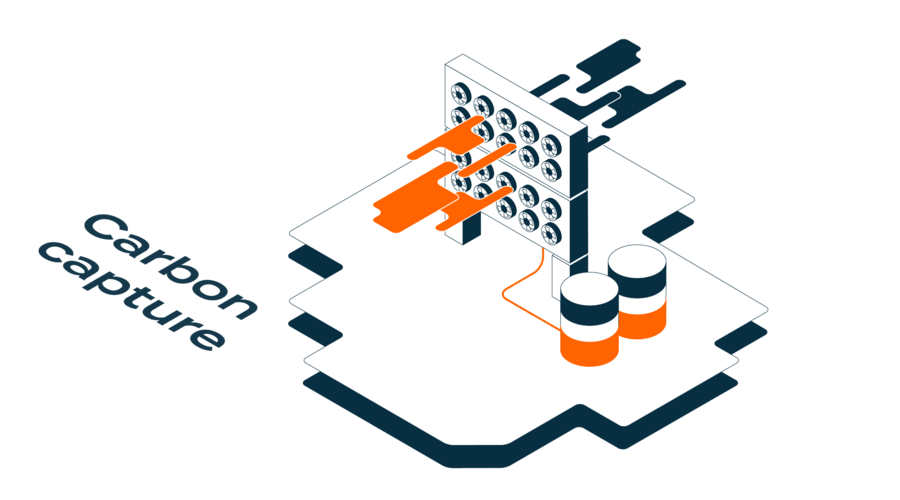

Sustainable utilization of CO₂

CCUS can be integrated into hydrogen production, storage and transportation processes to capture and store carbon dioxide (CO₂) emissions. The technologies can also be integrated into hydrogen utilization processes such as fuel cells or hydrogen combustion to capture CO₂ emissions produced during the combustion or reaction of hydrogen. In addition, CCUS can be embedded in hydrogen refining and purification processes to capture CO₂ emissions arising from the purification of hydrogen gas.

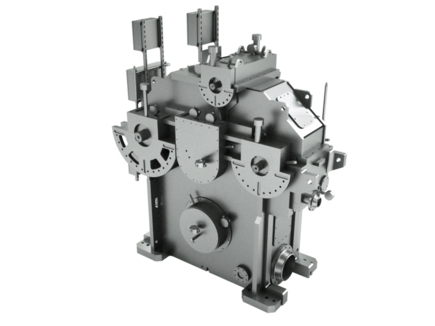

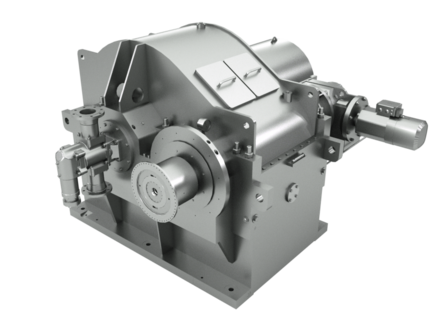

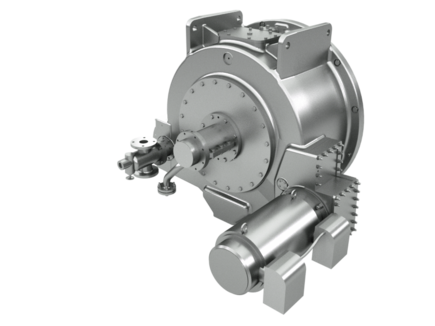

Our drivetrain components for the hydrogen process stream

Related topics and stories

Send us your questions and demands.

Get in touch with our engineering experts to discuss your questions and how we can contribute to your project success.