NVH chassis dynos (R&D)

- 01“True Turnkey” service

- 02Modular and expandable

- 03Unique control and testing capabilities

Our technologies for your demands

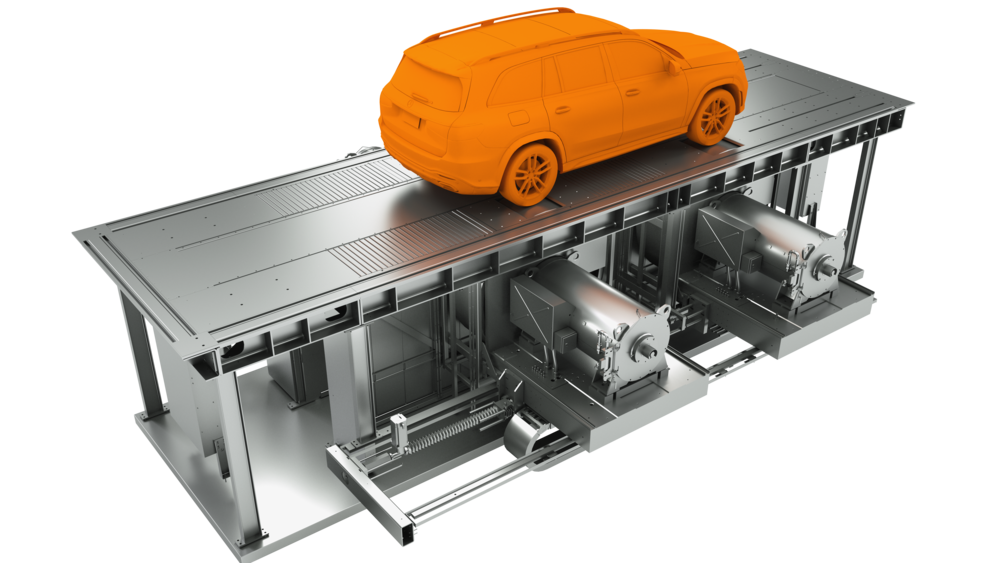

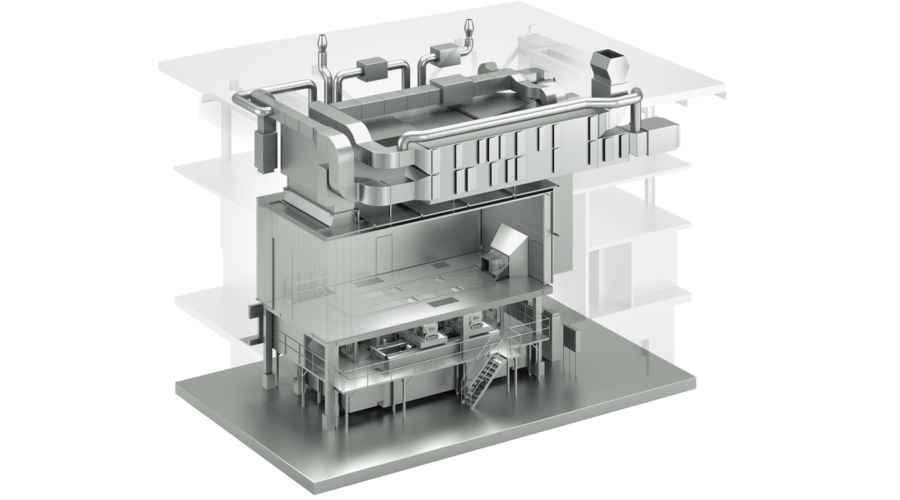

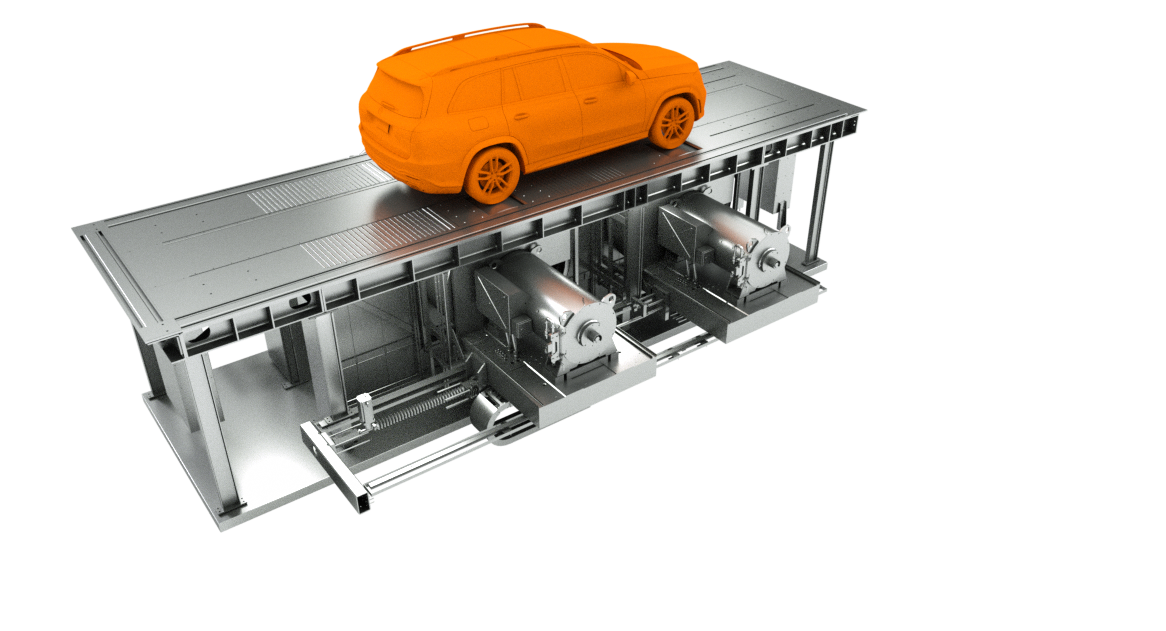

A special version of the performance chassis dyno represents the NVH chassis dyno, which is required for the measurement of noise (N), vibration (V) and harness (H) on the vehicle. In order to enable these measurements, there are very special requirements for this test stand, such as noise-minimized design of the roller units, soundproofing of the test hall or sound-reduced design of the air conditioning.

Common tests with an NVH test stand are:

Interior acoustics:

- Measurement of interior vehicle noise

- Identification of interior noise sources

- Identification of transmission Transmission The function of a vehicle transmission is to adjust the torque and speed, and to transfer engine power to the drive wheels. paths of structure-borne sound

- Vibration investigations

Exterior acoustics:

- Measurement of engine and exhaust system noise.

- Measurement of the rolling noise of the tires

- Pass-by measurements

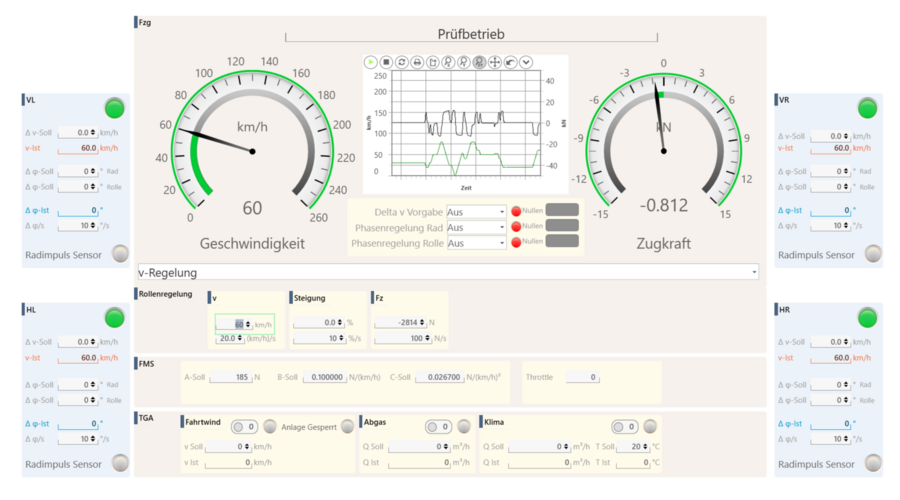

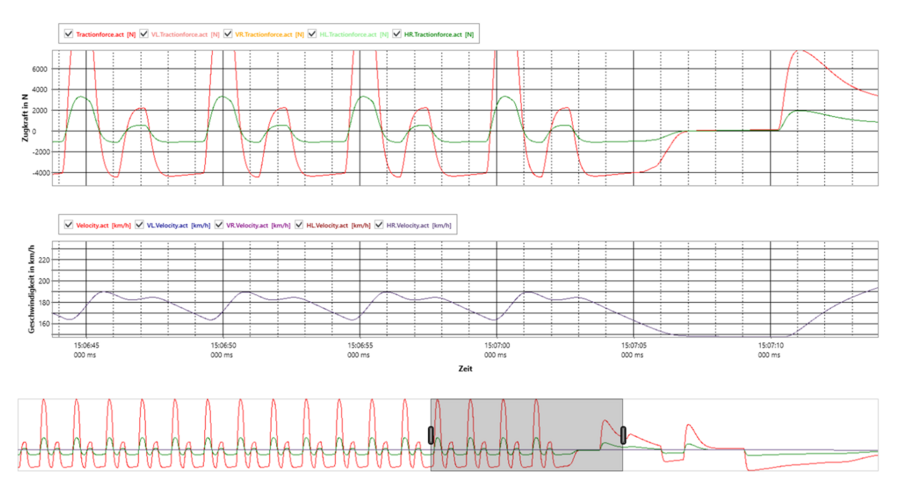

With the RENK RDDS automation system, a tool is available for these measurements with which the test engineer can very easily create test and measurement programs himself with the greatest flexibility, which can then be carried out with the highest accuracy and reproducibility.

And for test systems Test systems Test systems evaluate the functionality, load capacity and wear of technical components under realistic conditions. such as an NVH chassis dynos, where the perfect interaction between test stand, measurement systems and technical building equipment has a decisive influence on the test task, our "true turnkey" service is crucial.

“True Turnkey” service exactly according to customer needs

Depending on their intended use, complete vehicle test stands also require extensive infrastructure on the building side (foundations, test chambers, exhaust and air-conditioning technology, power and media supply, etc.). In addition, a wide range of measurement equipment has to be integrated and automated test runs created. For us, "true turnkey" means clarifying with the customer all the necessities of his test stand project and processing an optimum scope of services for the customer. From the basement to the roof. From planning to implementation.

Modular and expandable test system for a wide range of testing tasks

The change of test requirements goes in line with the further development of the vehicles. For this reason, complete vehicle test stands, which are usually operated for decades, must have a very high flexibility. The adaptation of new specimens or the modification of test programs can be carried out by the operators of our test benches themselves. For more extensive adaptations, our experienced service team is at your disposal.

RDDS automation system

Our RDDS test stand automation system combines control and measurement tasks in one package. Test programs can be easily prepared and then executed using graphical operator guidance. A real-time interface enables direct communication with the vehicle's CAN bus. All recorded measured values can be visualized and archived online.

Features

- NVH Chassis Dynos for the development of passenger cars and commercial vehicles.

- Customized total solutions for the entire required performance range

- High modularity

- State-of-the-art drive technology Drive technology Drive technology involves the generation, transmission, and control of mechanical movement in machines and vehicles.

- High reliability and durability

- RENK RDDS test bench automation and data acquisition

Get in contact with our experts from

Team Automotive: