Test rigs for turbine components

- 01Test rig components and total systems

- 02Combined MTC loads

- 03Powertrain design at the very highest level

Our technologies for your demands

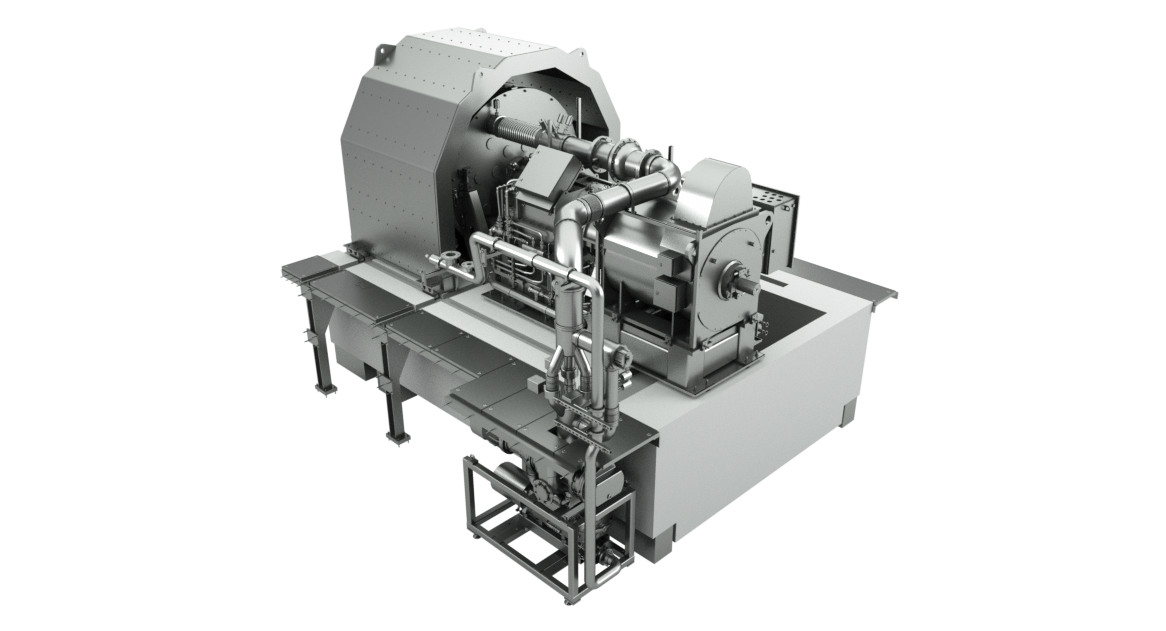

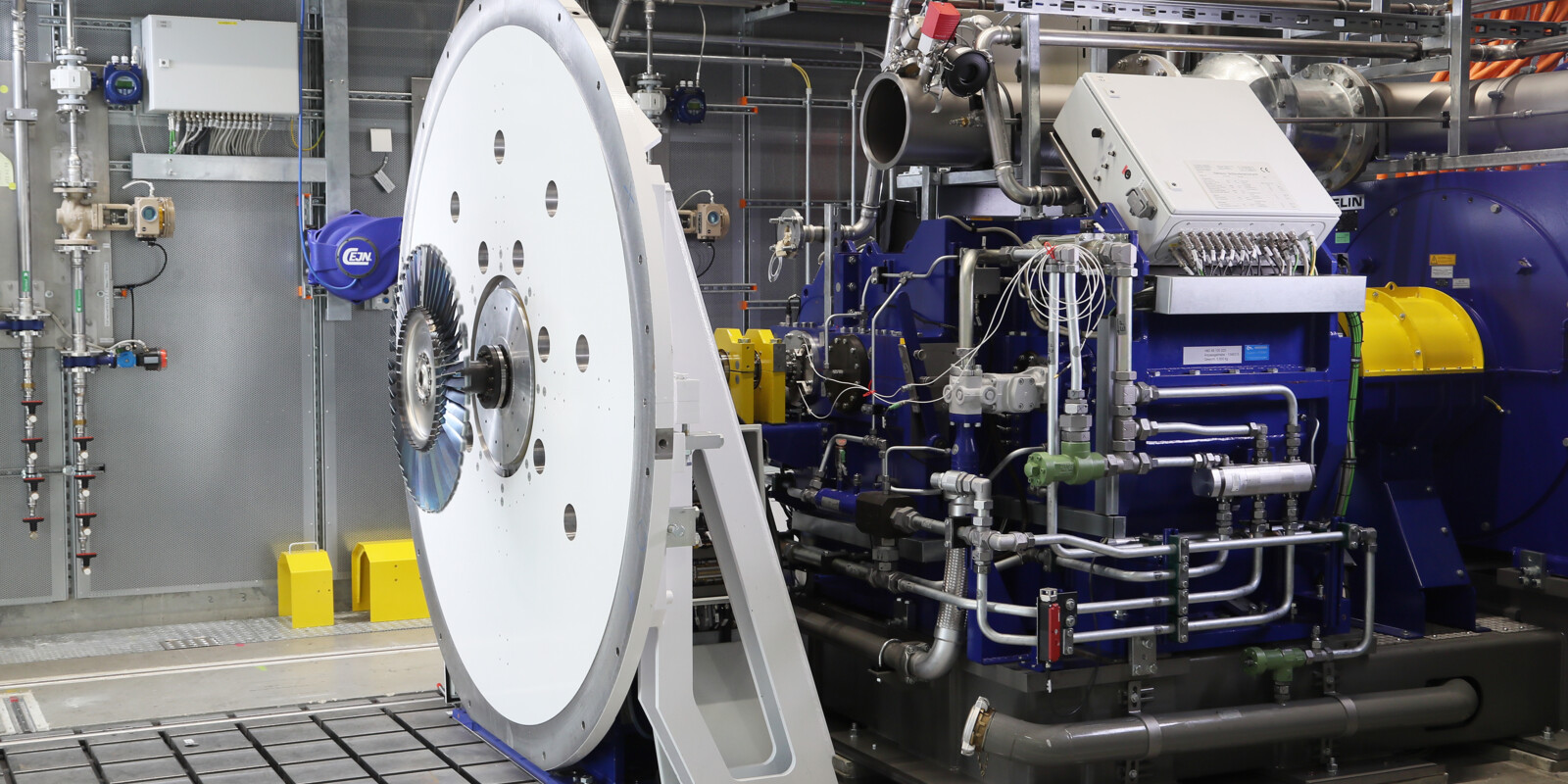

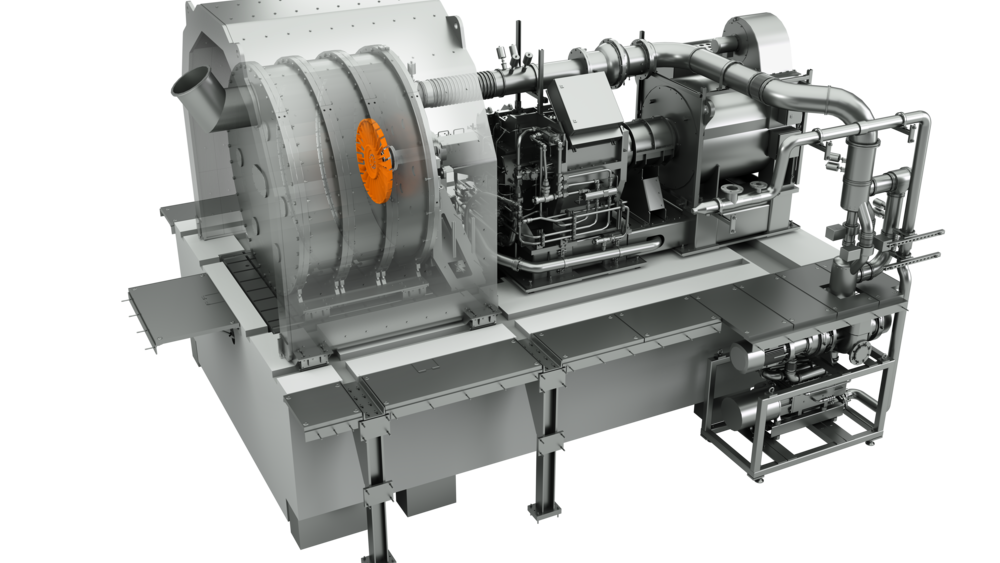

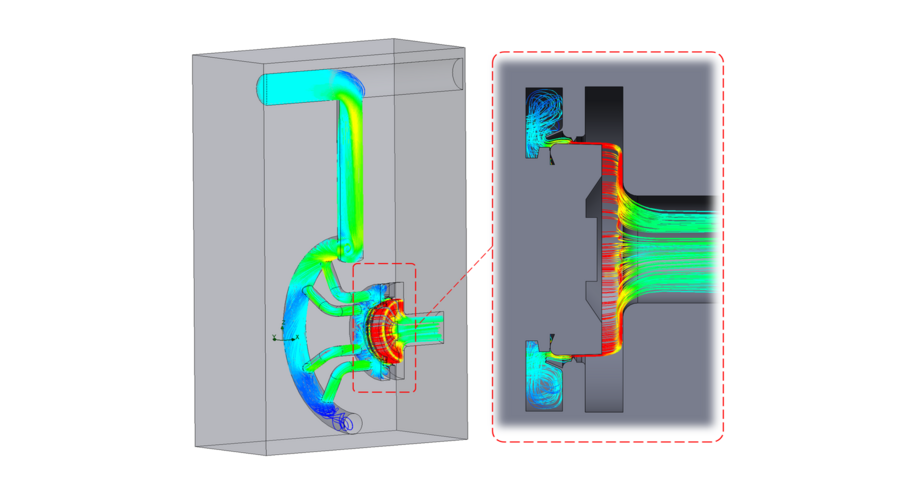

RENK test rigs can be used to perform high-speed tests on rotating engine components. These are usually compressor and turbine disks, blades, blisks or a combination of these. Depending on the test objective, the tests are performed both in vacuum and under atmosphere.

Among other things, the following tests can be carried out:

- Overspeed tests

- Low cycle fatigue test (LCF test)

- Blade excitation tests (superposition of static and dynamic loads)

- Containment tests

- Tests on sealing systems, especially brush seals

- Tests on engine bearings

- Impact of foreign bodies (e.g. birds) on engine blades

- Tests on engine sensors and measurement equipment in simulated engine environment

In addition to the core test rig development and assembly, our work on these complex systems often starts with the initial planning of the plant and the feasible testing options. Even during the later operation of the plant, RENK remains a reliable partner for application support as well as maintenance or adaptation work.

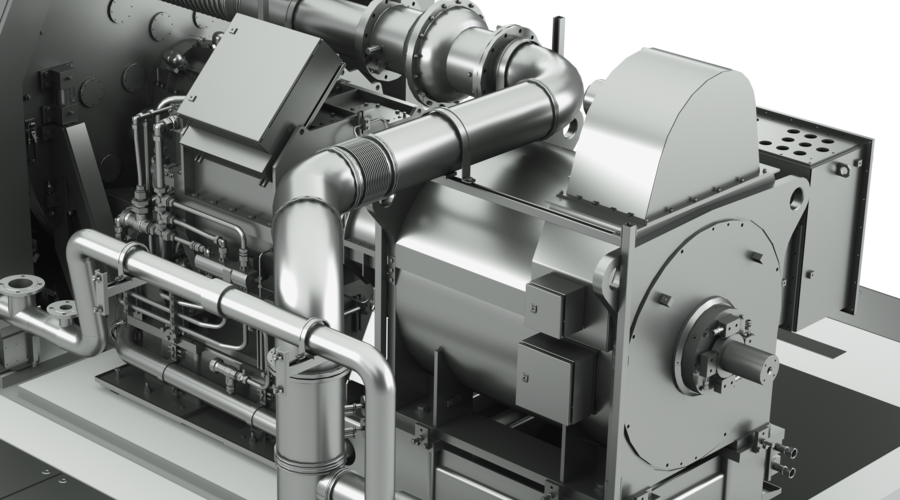

High speed in every component

In addition to turnkey test rigs, RTS also offers individual powertrain components or test item supports for use in turbine test rigs. Regardless of whether it is a component or an entire system, the focus is always on taking into account all customer-specific requirements to ensure optimum test results.

Maximum expertise – maximum support

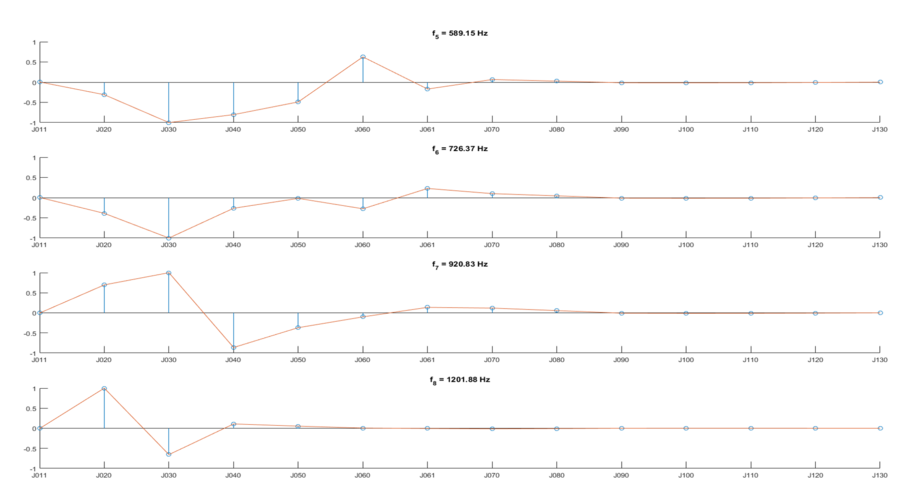

When working with these extremely high speeds, detailed modeling and calculations of all rotating components are the key to a satisfactory system. Using common and in-house design procedures, RENK specializes in the dimensioning of such drive trains. Our service does not end with the handover of the test rig to the customer. When changing test specifications or integrating new test specimens, we can simulate the behavior of the powertrain in advance in order to initiate suitable actions for system optimization together with the customer even before the first real tests. This guarantees the highest possible and sustainable availability of the test system Test systems Test systems evaluate the functionality, load capacity and wear of technical components under realistic conditions. .

Mechanical + thermal + chemical stresses

MTC testing is understood to mean that the loads occurring in reality due to mechanical, thermal and chemical stresses are not only simulated individually, but superimposed in a single test procedure. The result is a much higher degree of realism in the development of turbine components than with separate tests.

Features

- Test rig components and turnkey test rigs for development and verification of rotating turbine components

- Unique powertrain design

- MTC tests

- Unrivaled reliability and durability

- Master RENK RDDS automation system and measurement acquisition