Flywheel brake dynamometers

- 01Automatically switchable flywheel masses

- 02Direct braking force measurement

- 03Certified test runs

Our technologies for your demands

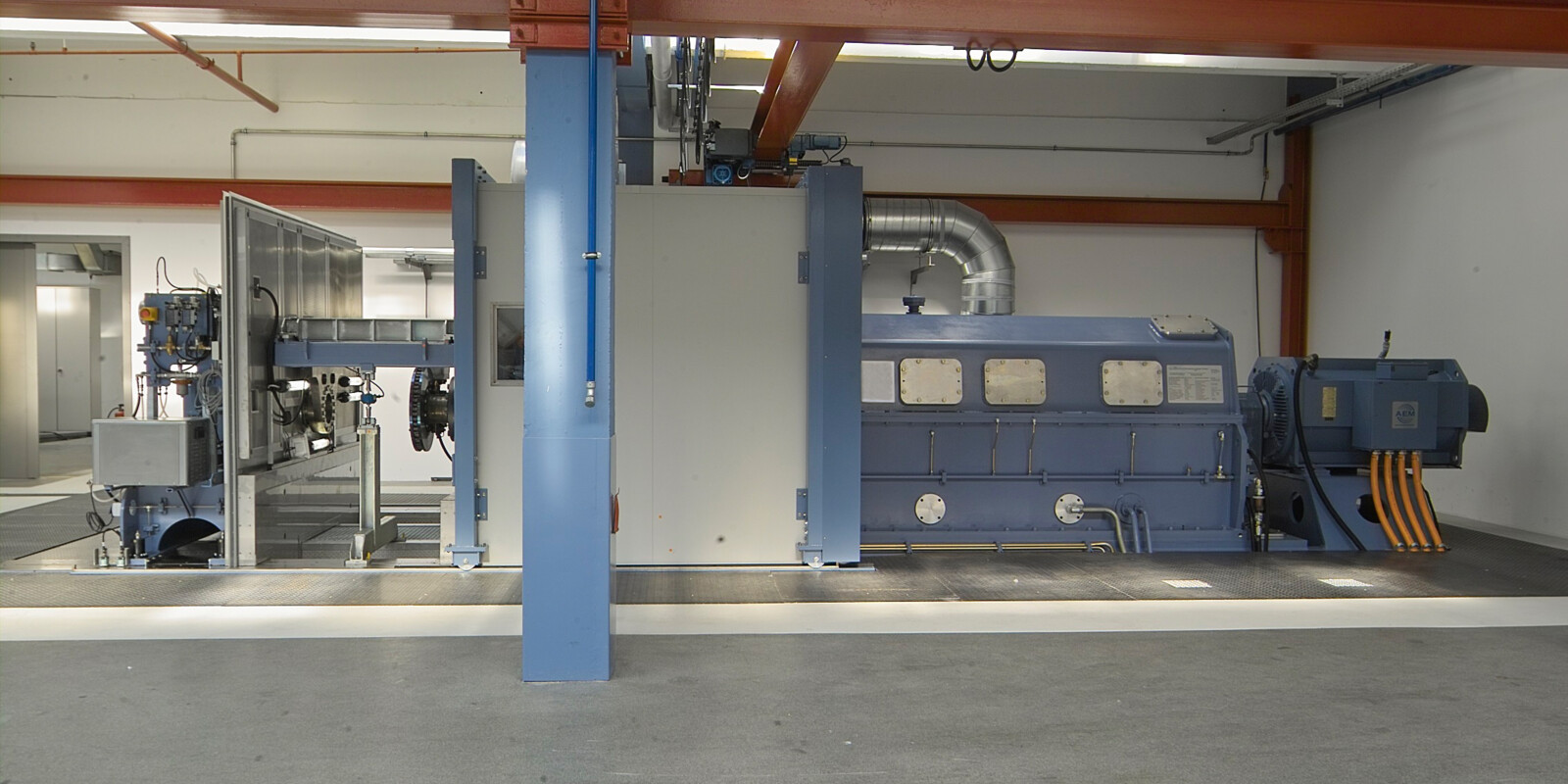

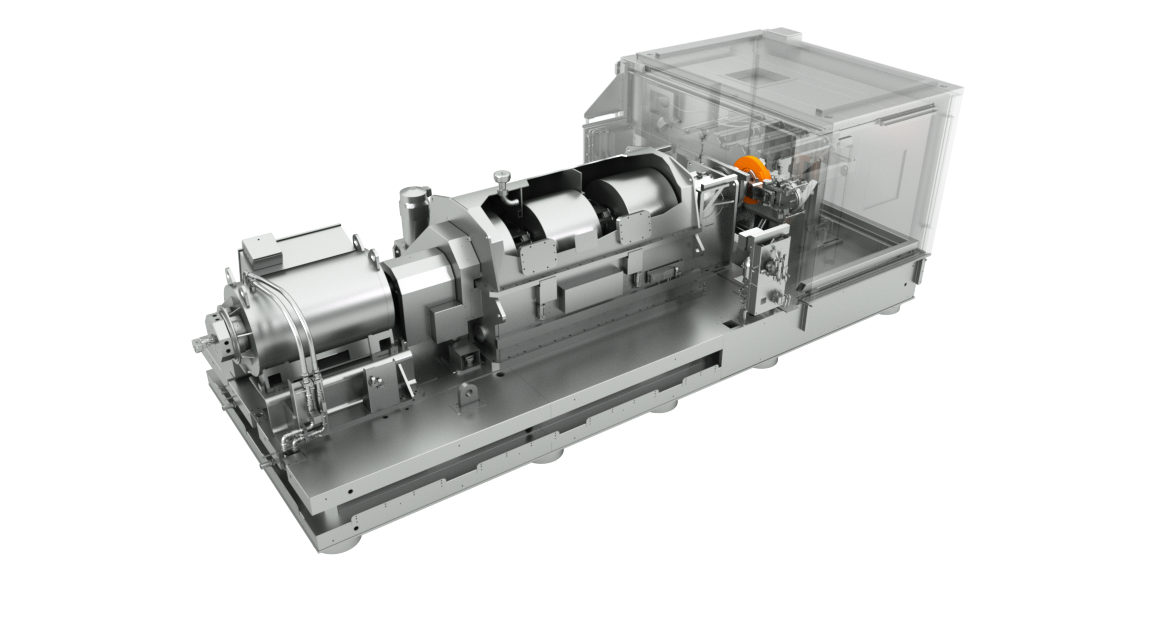

A reliable braking system has always stood for driving safety. Flywheel brake dynamometers from RENK are designed for the optimization of existing brake systems and development of settings for future rail vehicles.

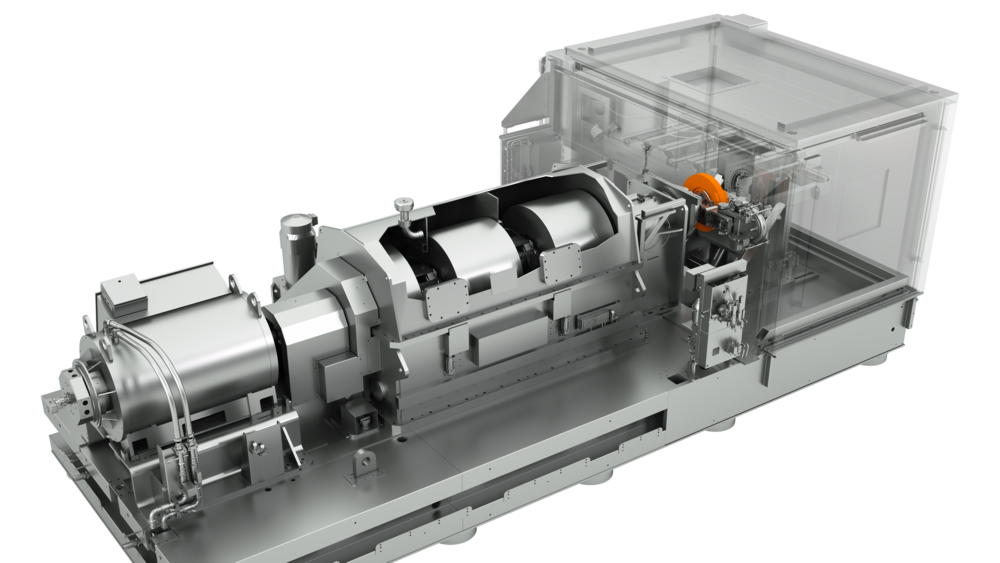

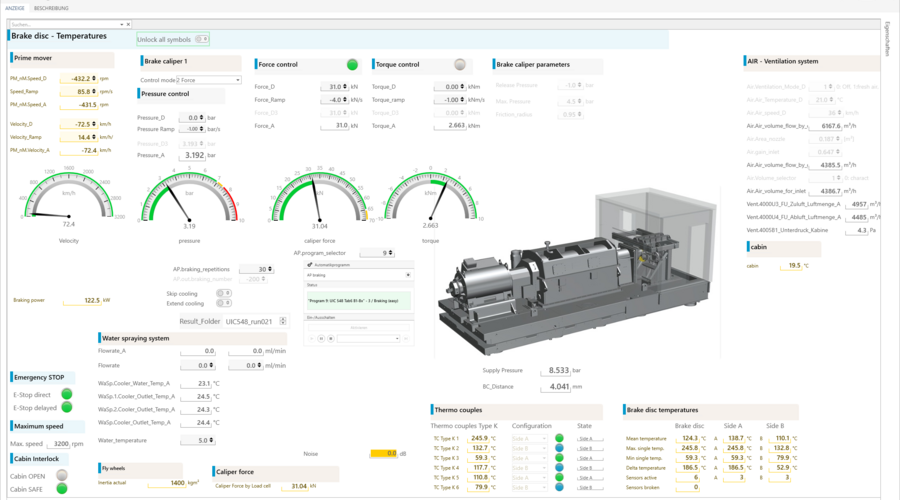

The number of flywheel masses used to simulate the inertia of the train can be selected according to customer requirements. An electrical mass simulation covers the intermediate ranges or, for certain requirements, even entire subranges of the total mass inertia.

The type of braking system, and the way braking pressure is generated are adapted to the specific project.

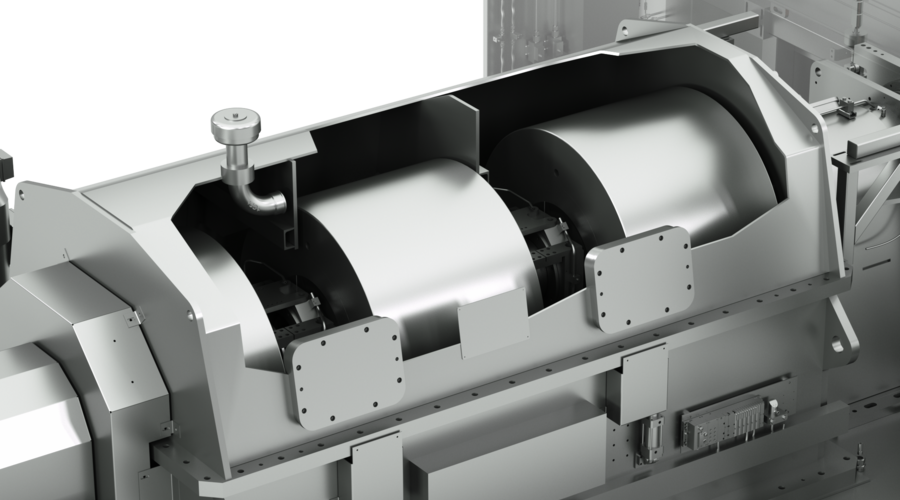

Automatically switchable flywheel masses

A key design characteristic of RENK brake dynamometers are the automatically switchable flywheel masses, which are used as standard. Controlled by test stand automation, this makes it possible to modify the simulated vehicle weight anywhere in the adjustment range without manual intervention even during a test run. This is the requirement for automatic long-term testing.

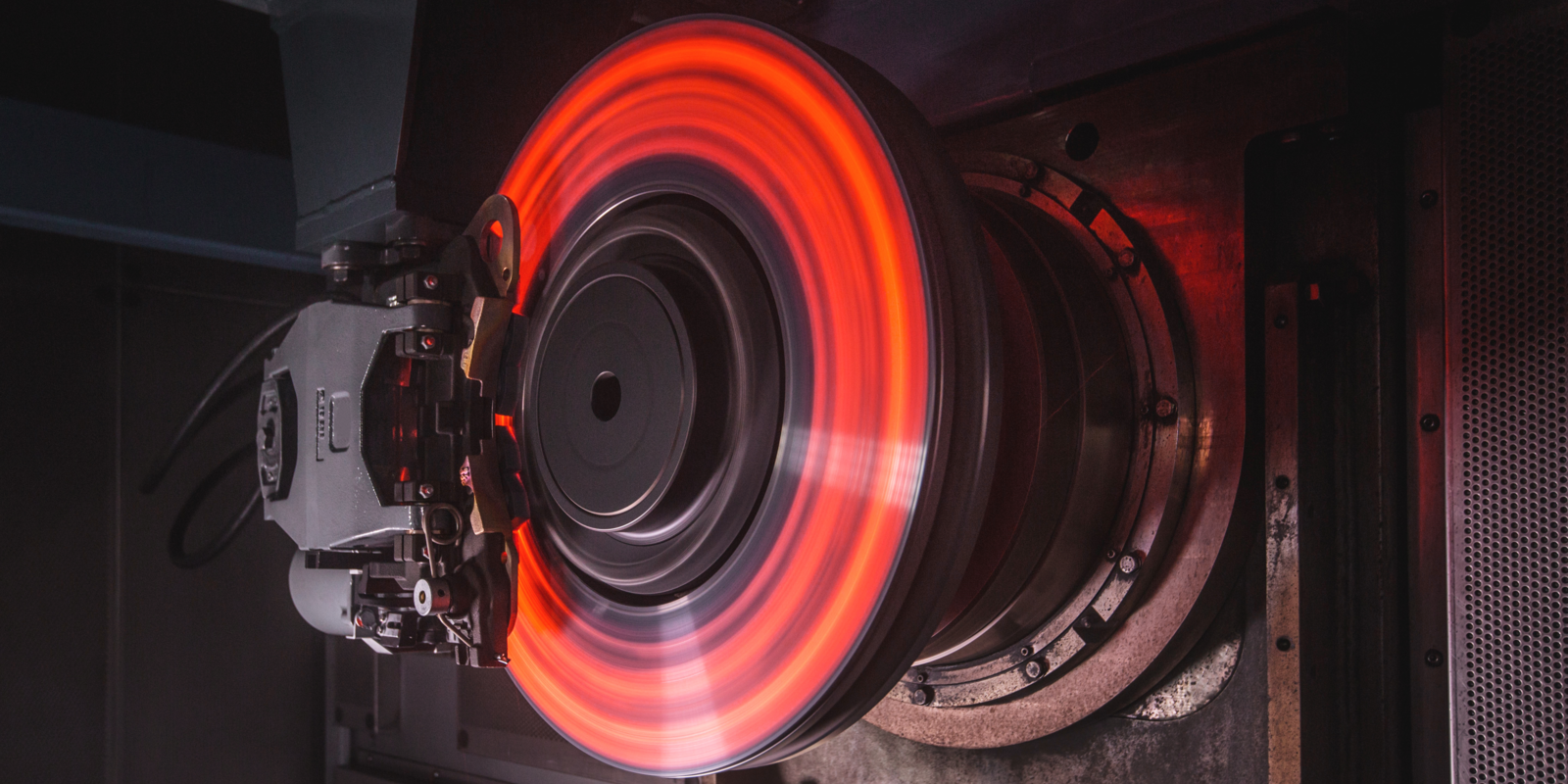

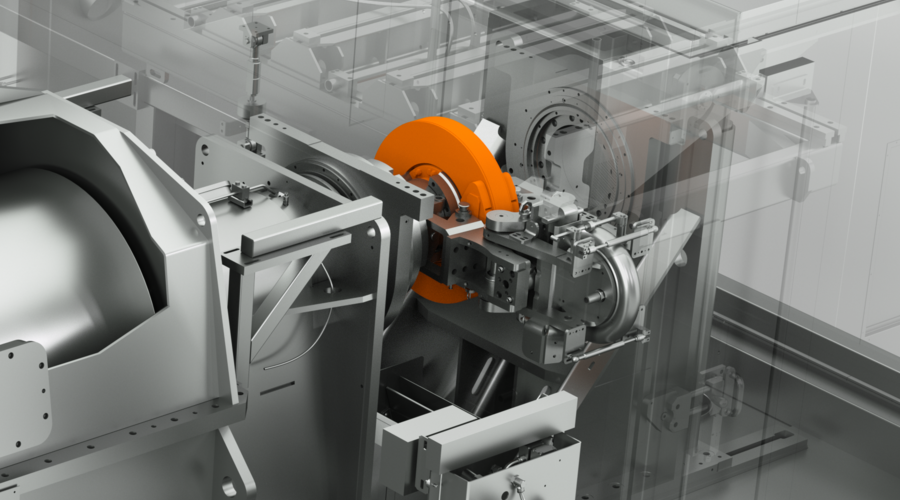

Direct braking force measurement

To obtain realistic brake values, we not only record the brake pressure in the brake cylinder, but also the real brake force at the brake caliper. A decisive advantage, especially for dynamic braking processes.

UIC audited

RENK flywheel brake dynos meet the standard UIC requirements according to UIC-541-3 and UIC 548 for the development of brake systems and their components. Other country-specific certifications (e.g. TB or AAR) can also be considered upon request.

For all certification measures, RENK can support the customer with great expertise.

Features

- Flywheel brake dynamometers for the optimization of existing and development of brake systems for future rail vehicles.

- Internationally certifiable test stands (e.g. according to UIC-541-3 / UIC 548)

- Automatically switchable flywheel masses and additional electrical mass simulation for continuous mapping of the vehicle masses

- Direct braking force measurement with load cell for optimized accuracy

- Hydraulic and pneumatic brake pressure generation

- Optional environmental simulation (rain, low temperature, snow, …)

- RENK RDDS test bench automation and data acquisition

Get in contact with our experts from

Team Railway: