InArm® has the lowest weight and space claim of all armoured vehicle suspension systems Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. and provides a growth path to advanced variable damping, lock-out and ride height management systems.

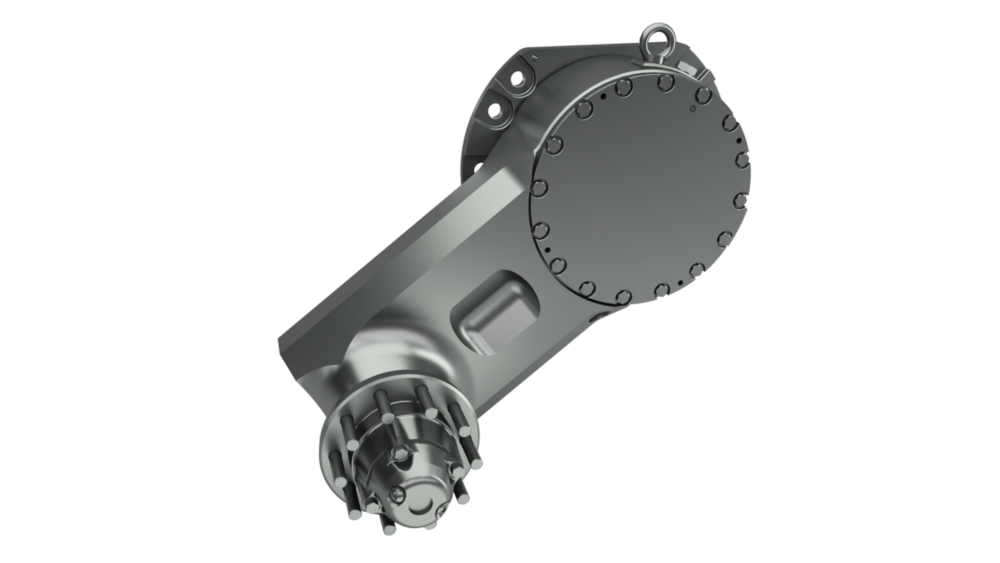

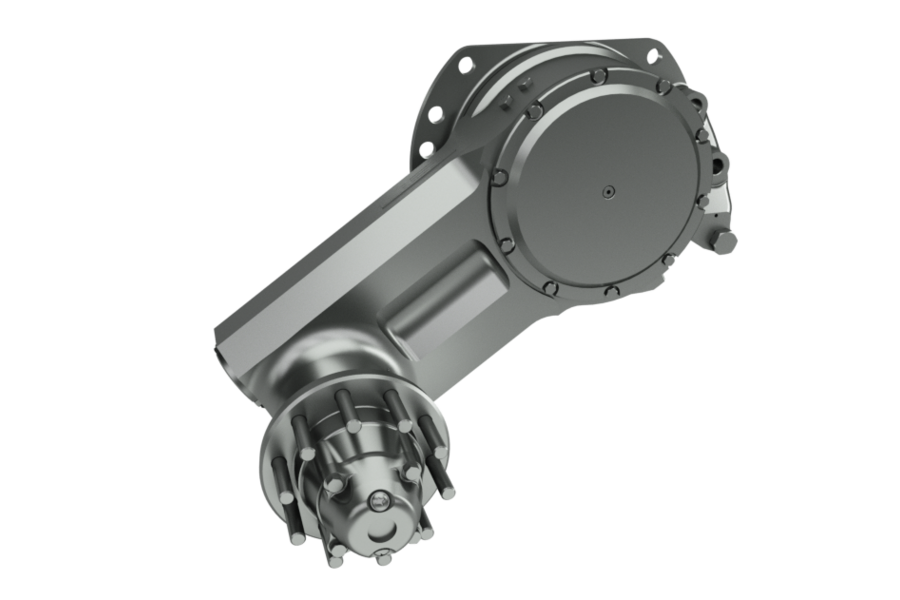

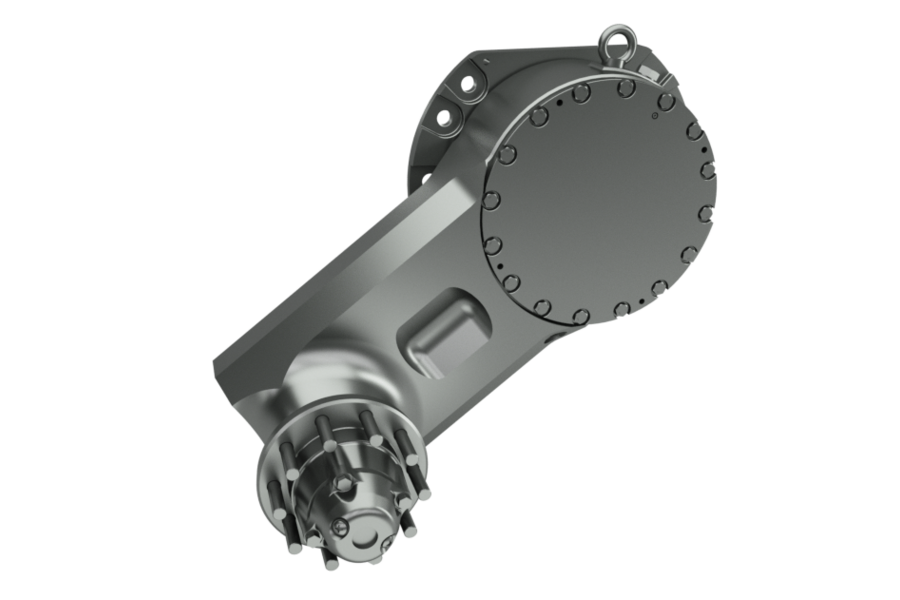

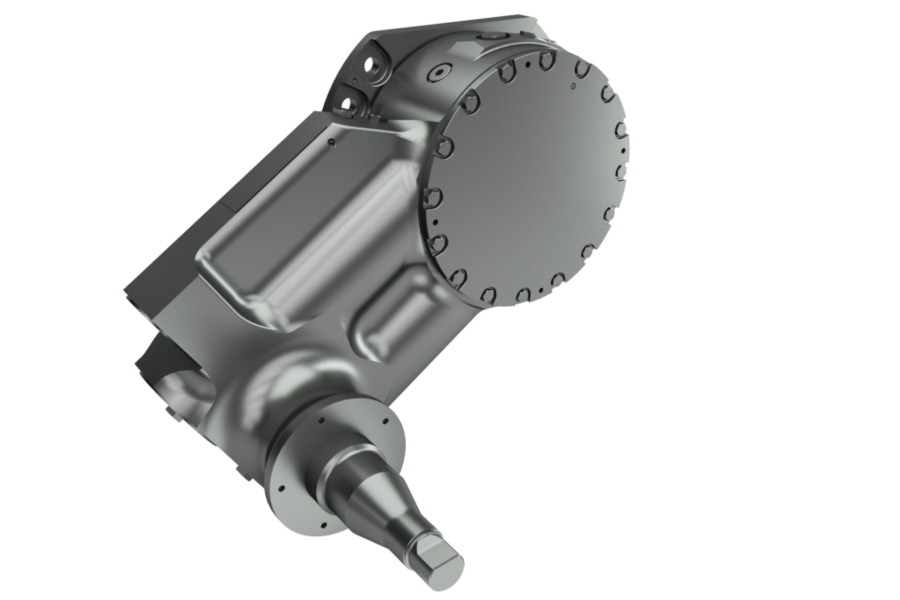

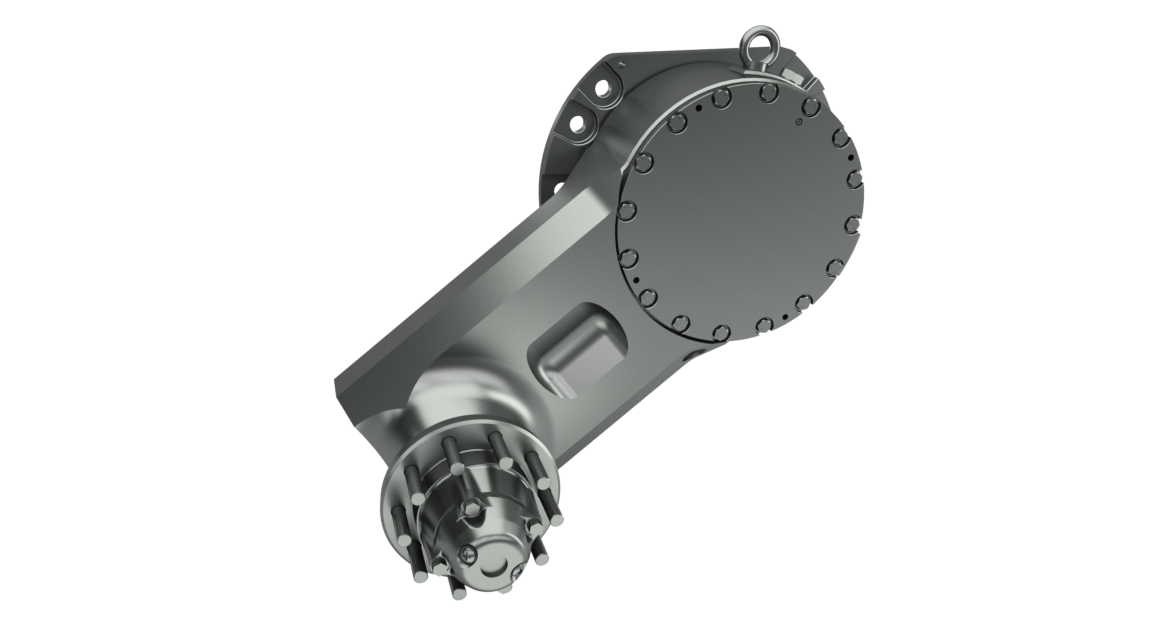

The Horstman InArm® hydro-pneumatic suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. uses high-pressure nitrogen gas and an integral oil damper that are all contained within the road arm. As a consequence this reduces weight and space, compared to other hydro products, HSU or coil solutions. Designed as the most efficient packaging space solution, InArm® provides a growth path to advanced variable damping, lock-out and ride height management systems.

Developed by Horstman in the mid-1990s initially for the UK MODs Future Scout Cavalry System (FSCS) Tracer and US Army’s Future Combat System (FCS) programs, InArm® is designed to eliminate the need for torsion bars and to minimize or eliminate road arm penetration of the vehicle hull.

Compact vehicle design, enhanced performance and survivability.

By removing the torsion bars and adopting an integrated system approach, we've not only saved mass but have also significantly enhanced the vehicle's operational capabilities. The external mounting of the independent suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. lowers the vehicle's profile, directly contributing to its survivability. Moreover, this setup provides a clear upgrade path for incorporating advanced suspension Suspension systems Suspension systems are designed to dampen the shocks and vibrations experienced when driving on uneven terrain. features and accessories, ensuring our vehicle remains at the cutting edge of military technology. This holistic approach exemplifies our commitment to innovation, performance, and the safety of those who operate our vehicles.

- Additional space for equipment, ability to have a floor mounted emergency escape hatch

- Reduced fragmentation effects from secondary projectiles from mine blast or IED blast

- Integration of damper and gas spring inside road arm minimizes space claim

- Simpler than a torsion bar system which needs separate road arms, bump stops, dampers, torsion bar attachments and protective tubes

- Damaged units can be replaced more easily than bent or seized torsion bars

- Reduced hull machining without precision alignment between left and right side of vehicle

- Ability to lower the turret basket and reduce the height of the vehicle gives improved survivability (lower silhouette)

- The saving of the hull side armour is typically 100-500kg

There is a upgrade path regarding ride height, lockout and semi active damping.

- Charging kit and Nitrogen Charging – Hydrobooster™

- External Lockout (engineering / special role)

- Wheel hub, lightweight wheels, wear guards, bump stops

Gallery

Application

Downloads

- Horstman - InArm (309 kB)

E-Mail angeben

Bitte geben Sie Ihre E-Mail-Adresse an, um den Download zu starten.

Get in touch with our specialists.